Electronic grade malonic acid

A malonic acid, electronic-grade technology, applied in the field of malonic acid, industrial mass production of malonic acid, can solve the problems such as the purity and quality can not meet the use of the electronic industry, the yield of malonic acid is low, etc., and achieve high use Value, Product Yield, Easy-to-Get Results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

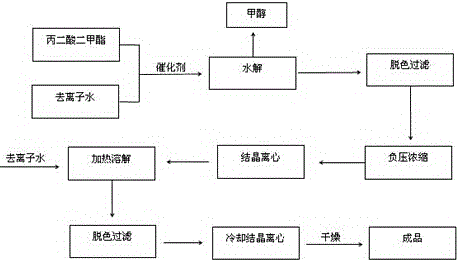

Method used

Image

Examples

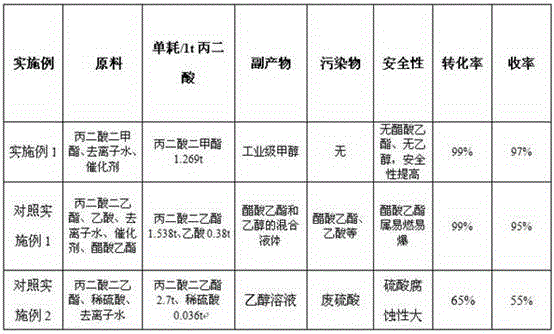

Embodiment 1

[0027] Put 132g of dimethyl malonate and 400g of deionized water in the glass reactor containing the treated catalyst, then start to heat up to 70-80°C, start hydrolysis under reduced pressure, and distill out crude methanol in 2-3 hours Solution, obtain malonic acid solution and measure the content of malonic acid, calculate the transformation rate of malonic acid more than 99%;

[0028] The malonic acid solution prepared above was decolorized and filtered, concentrated under negative pressure, and crystallized and centrifuged to obtain 95.1 g of malonic acid crude product, and recovered the centrifuged mother liquor to obtain 7.1 g of malonic acid crude product. Combine the crude malonic acid and add 50g of deionized water to heat and dissolve, filter and decolorize, cool and crystallize and centrifuge to obtain the semi-finished product of malonic acid, and finally dry it to obtain 101.4g of electronic grade finished product of malonic acid. The content is above 99.5%, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com