Module combination type microcirculation biological nitrogen removal reactor and method thereof

A biological denitrification and reactor technology, applied in chemical instruments and methods, biological treatment devices, biological water/sewage treatment, etc., can solve the problem of easy aggregation of organisms into granular sludge, low cell yield, and no application, etc. problems, achieve high engineering application value, accelerate biological denitrification reaction, and facilitate manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

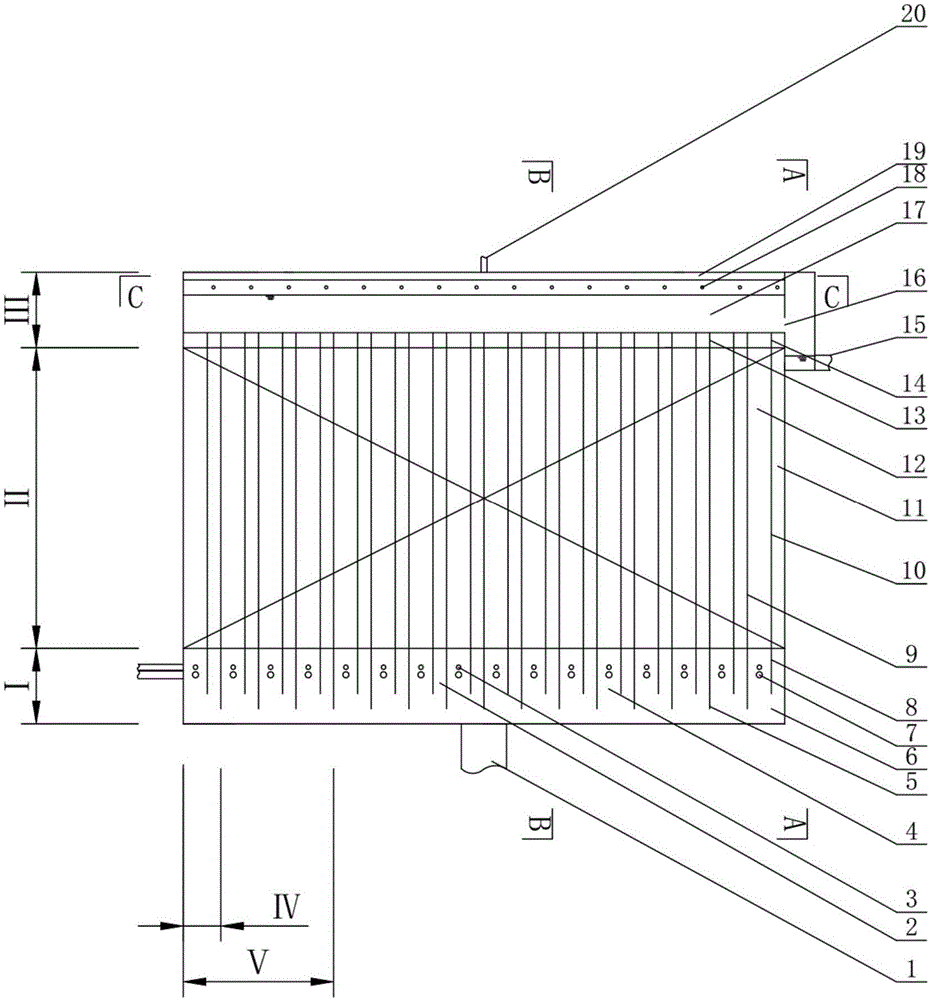

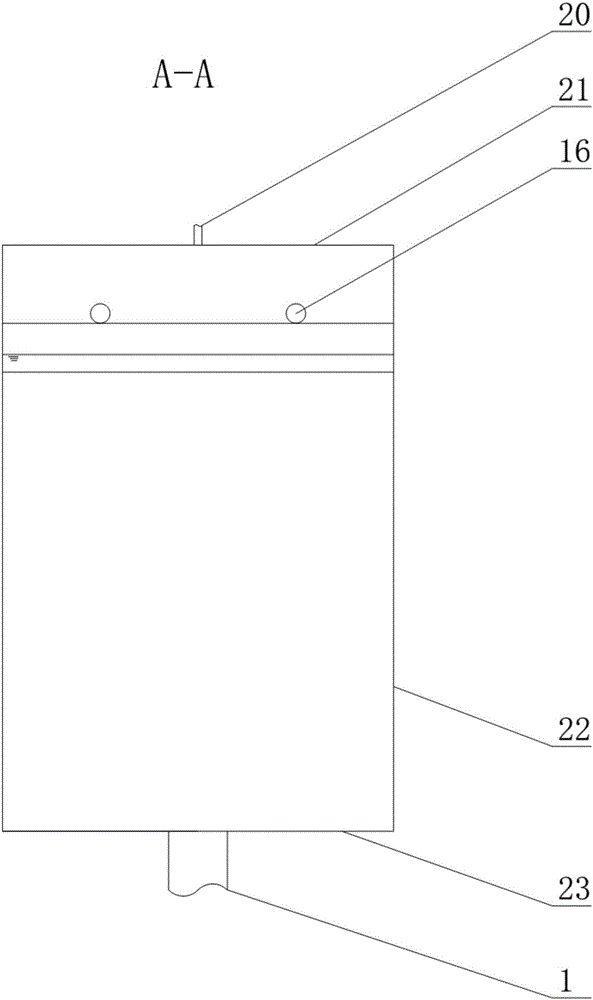

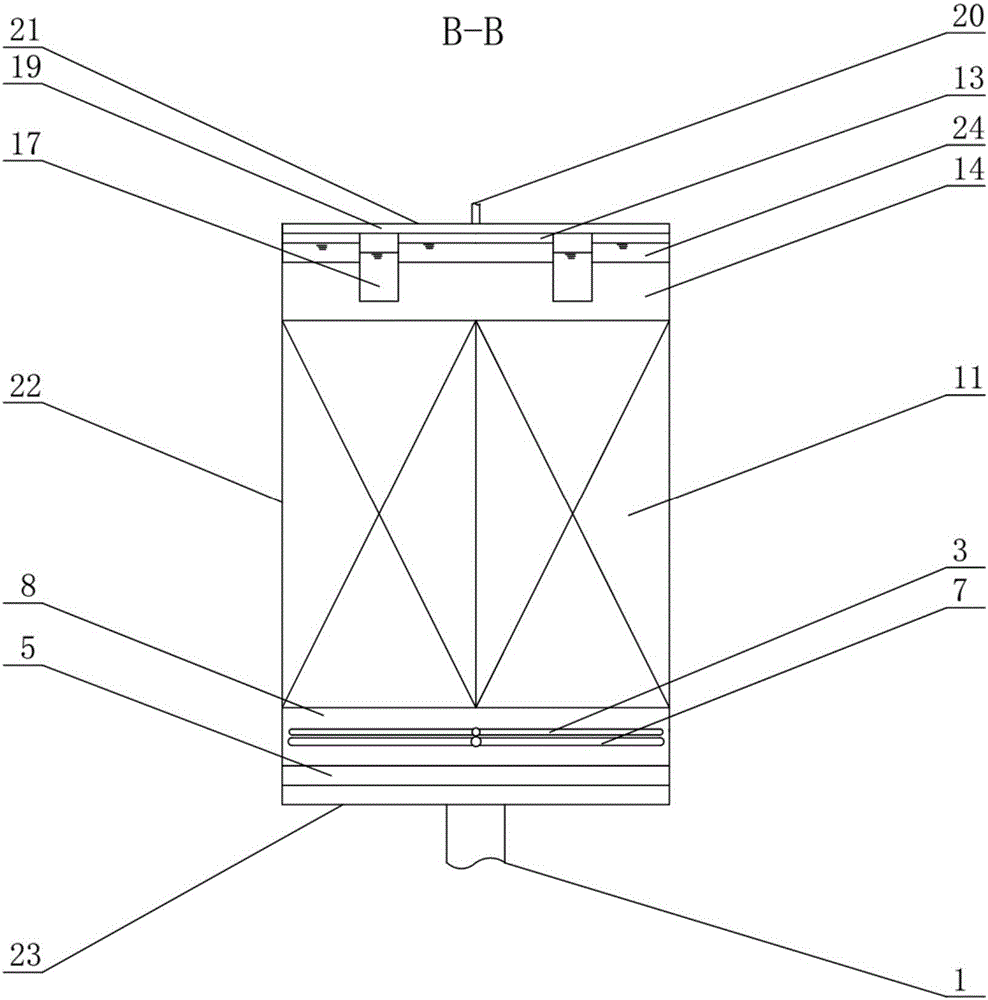

[0022] The purpose of the present invention is to overcome the deficiencies of the prior art and provide a modular combined microcirculation biological denitrification reactor.

[0023] Such as Figure 1-5 As shown, a combined microcirculation high-efficiency biological denitrification reactor, the main body of the reactor is a container body, and the ratio of the length, width, and height of the container is 6.0~6.5:2.0~2.5:3.0~3.5; the inside of the container is composed of several modules V Combined, in this embodiment, two modules V are arranged in parallel rows when viewed horizontally, that is, two rows are arranged in the width direction of the reactor. According to needs, one or more rows of modules V can be arranged in the width direction of the reactor; Modules V are combined into columns.

[0024] The ratio of the length, width and height of each module V is 1:1:3~3.5, and each module V is divided into four units IV vertically, which perform denitrification functio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com