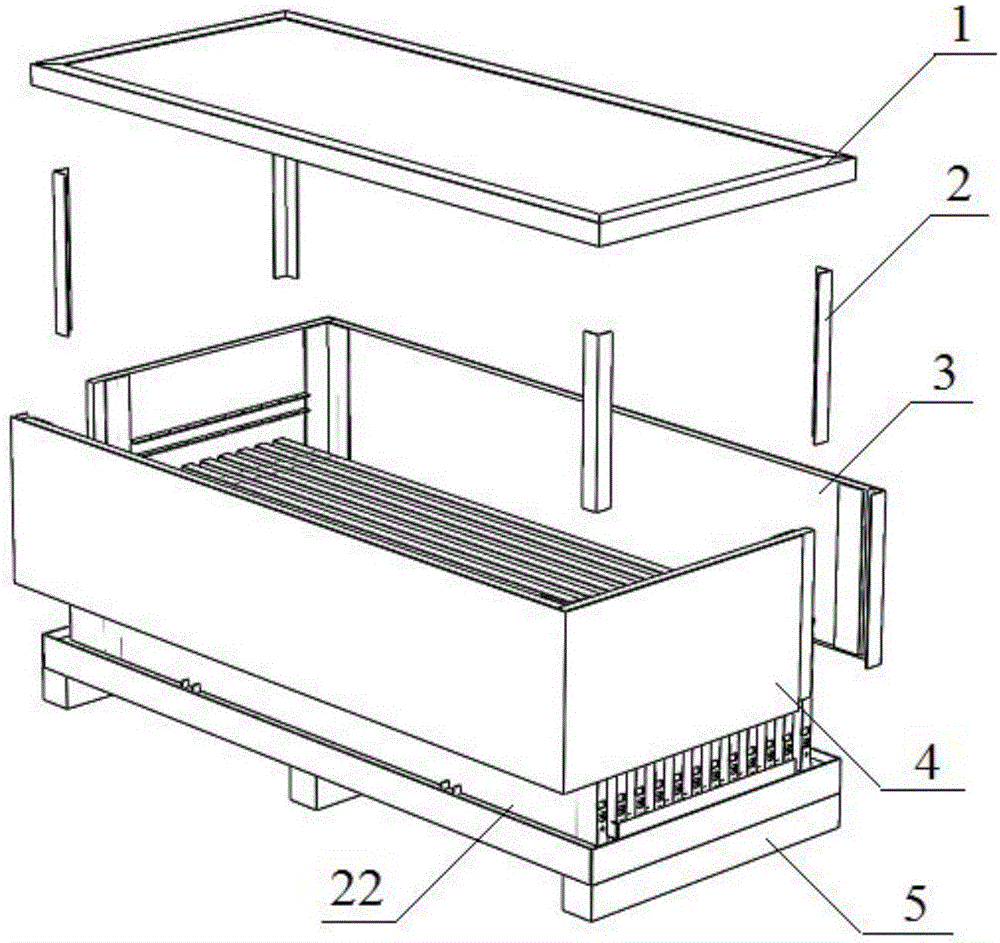

Electromechanical product heavy paper packing case based on packaging unit and packing method thereof

A technology for electromechanical products and packaging boxes, applied in packaging, transportation and packaging, rigid containers, etc., can solve the problems of unfavorable placement and removal of goods, inconvenient transportation and storage, and low forming efficiency of heavy cartons, so as to reduce packaging logistics costs. , Reduce the cost of storage and transportation, the effect of excellent load-bearing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Packaging for automotive stainless steel trim. Such as Figure 11 shown. On the corrugated cardboard 20, a card holder 19 made of EPE or EPS is bonded.

[0035] The automobile stainless steel decorative strip is embedded on the deck 19 to form a combined packaging unit. then press Figure 9 The method shown is packaged.

[0036] The components on the packaging unit are not limited to the above, and can also be component products of other shapes, sizes and textures.

Embodiment 2

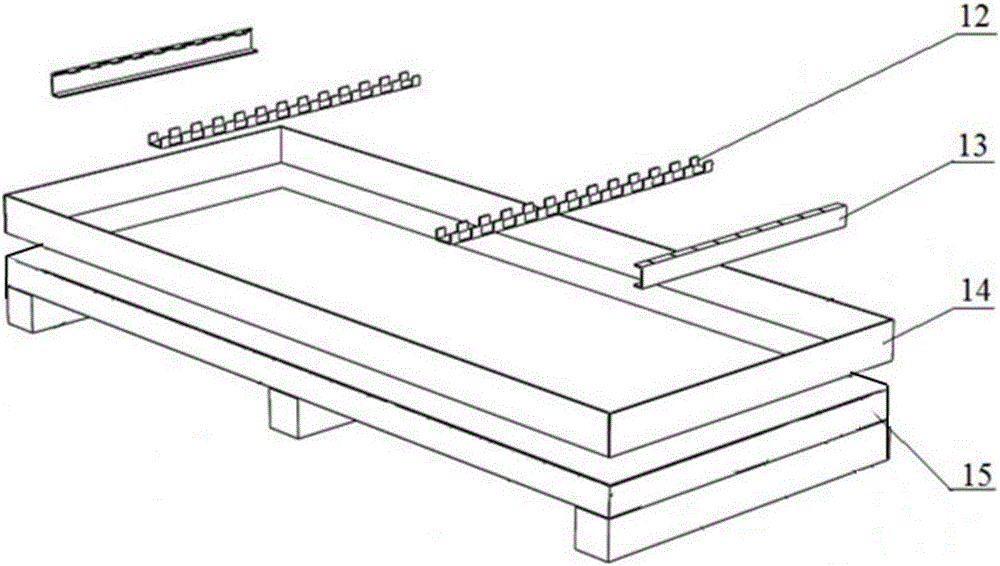

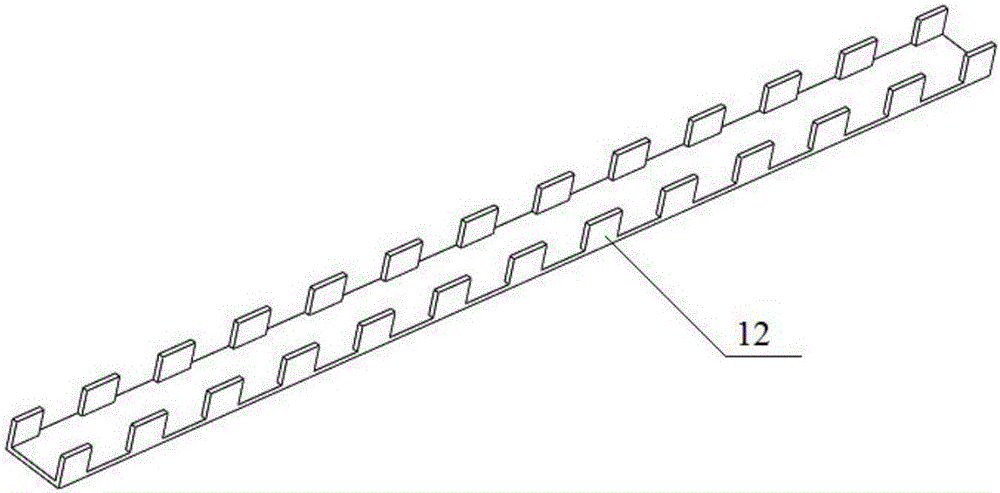

[0038] It is used for the packaging of thin plate products such as elevator car wall panels. During implementation, process according to the embedding size of the elevator car wall panel image 3 , Figure 4 The shown middle part paper corner bracket 12 and two rows of end corner brackets 13, and the notch on the corner bracket 9 on the case plate are used for mounting the elevator car wall plate. then press Figure 9 The method shown is packaged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com