Honey comb structure paper board package box of 180 degree two-double and production method thereof

A technology of honeycomb cardboard and packaging boxes, which is applied in the fields of carton/carton manufacturing machinery, packaging, transportation and packaging, etc., which can solve the problems of occupying a large warehouse, occupying a large space for vehicles and ships, and high transportation costs, so as to reduce storage and transportation Space, transportation cost reduction, cost saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

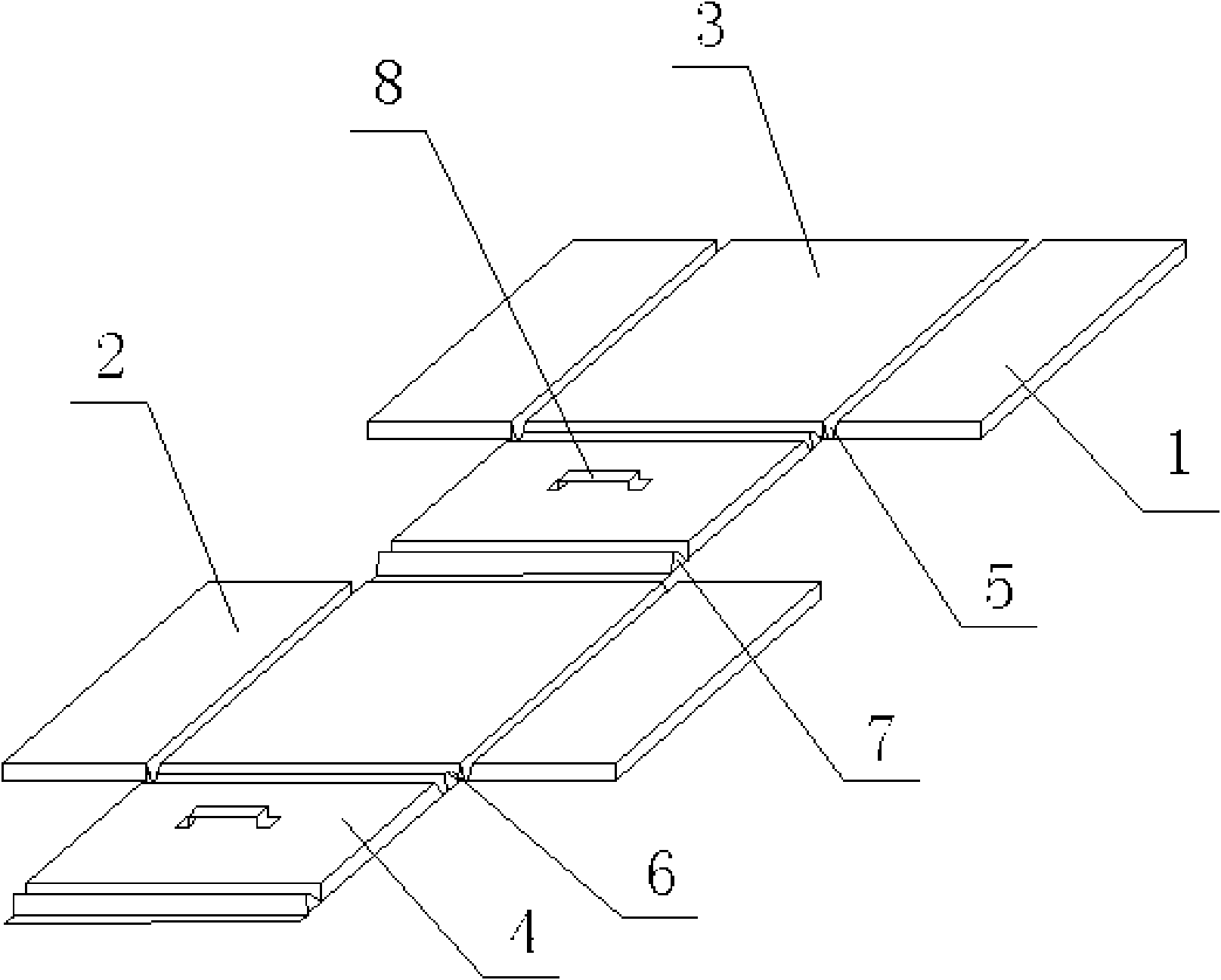

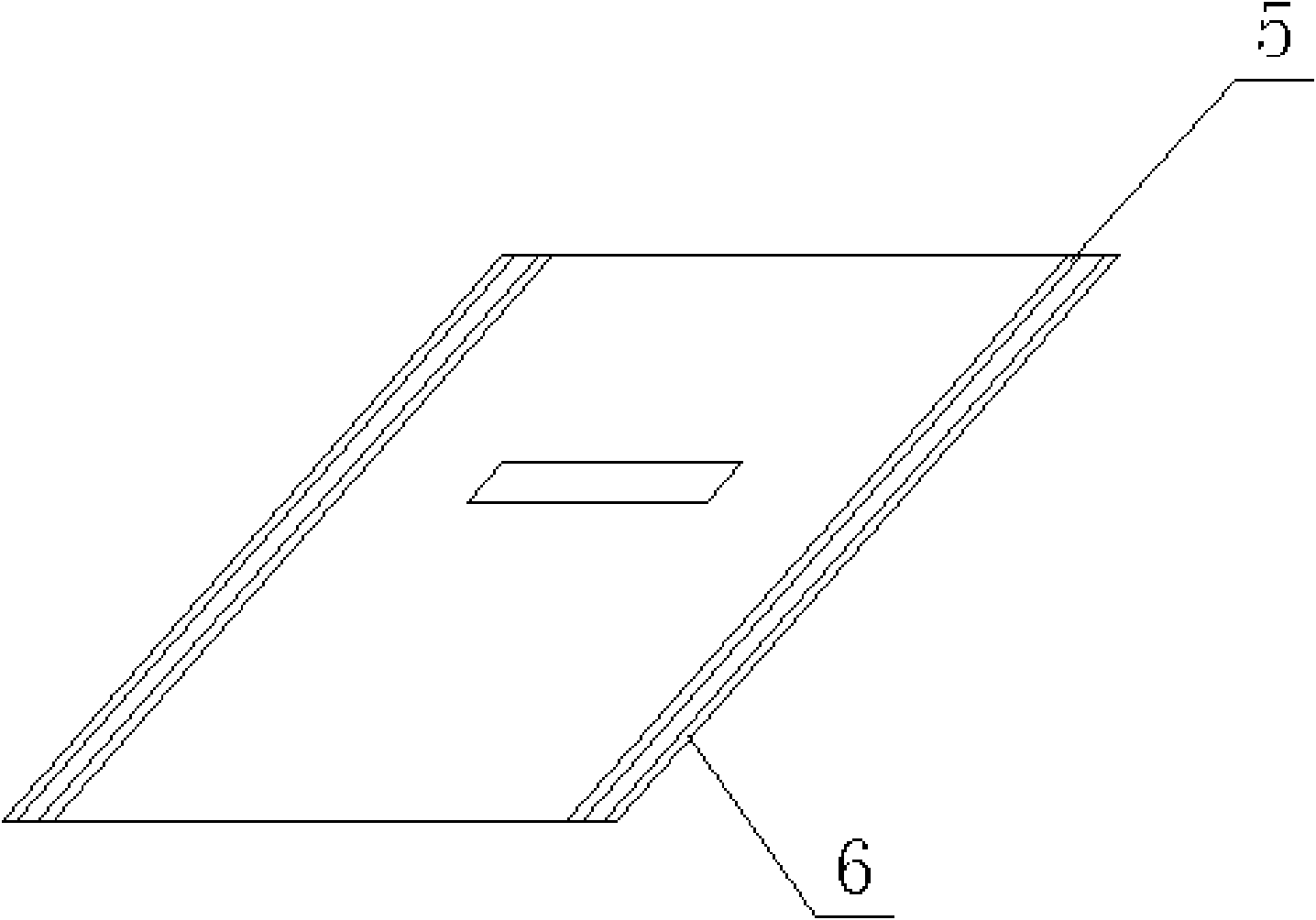

[0012] Embodiment: The honeycomb cardboard packaging box in this embodiment includes a bottom plate 1, a cover plate 2, front and rear side panels 3 and left and right side panels 4 connected to the bottom plate and cover plate, and the bottom plate 1 and the front and rear side panels are connected by a single pressure wheel. 3 and the connection between the cover plate 2 and the front and rear side panels 3, and press a connection indentation 5, at the connection between the left and right baffles 4 and the front and rear side panels 3 and the distance from the connection is twice the thickness of the honeycomb cardboard One indentation is pressed by the two pressing wheels to form one connection indentation 5 and one folding indentation 6, and the connection indentation and the folding indentation are approximately triangular 7. A handle 8 is respectively provided on the left and right baffle plates. The folding indentation of the left and right baffles is folded 180 degree...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com