A dynamically reversible adjustable bichiral nanostructure and its preparation method

A nano-structured, chiral technology, applied in chemical instruments and methods, other chemical processes, vacuum evaporation plating, etc., can solve problems such as high experimental costs, and achieve the effect of reducing experimental costs and consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

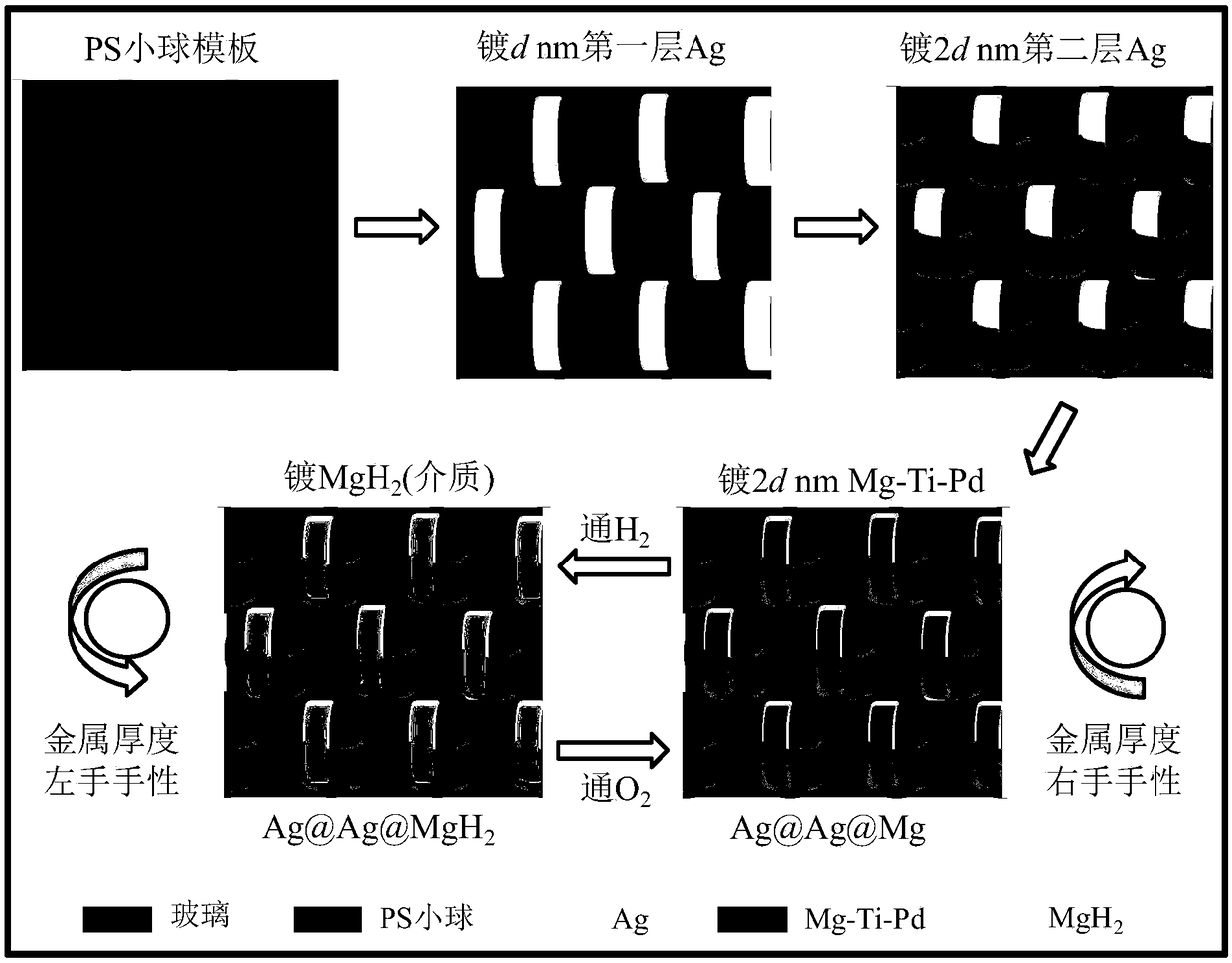

[0034] A dynamically reversible adjustable bichiral nanostructure, the bottom surface of the structure is L-shaped, the short side of the L-shape is a metal material, and the thickness is 20nm; the long side of the L-shape is a four-layer structure, the bottom layer is a metal material, the thickness The metal material is a gas-sensitive metal material with a thickness of 20nm, and the gas-sensitive metal material is an isolation layer with a thickness of 2nm; the upper layer of the isolation layer is a catalytic layer with a thickness of 2nm.

[0035] In this embodiment, the metal material is Au; the gas-sensitive metal material is Mg; the isolation layer is Ti; and the catalytic layer is Pd.

[0036] The preparation method of the bichiral nanostructure with dynamic reversible adjustment in this embodiment comprises the following steps:

[0037] Step 1, prepare at least five 1cm*2cm glass pieces a and two 1cm*1cm glass pieces b, and clean them up. The specific cleaning proces...

Embodiment 2

[0048] A dynamically reversible adjustable bichiral nanostructure, the bottom surface of the structure is L-shaped, the short side of the L-shape is a metal material, and the thickness is 100nm; the long side of the L-shape is a four-layer structure, the bottom layer is a metal material, the thickness 50nm, above the metal material is a gas-sensitive metal material with a thickness of 100nm, above the gas-sensitive metal material is an isolation layer with a thickness of 8nm; above the isolation layer is a catalytic layer with a thickness of 8nm.

[0049] In this embodiment, the metal material is Ag; the gas-sensitive metal material is Mg; the isolation layer is La; and the catalytic layer is Pd.

[0050] The preparation method is the same as the preparation method in Example 1, the difference is only in step 9: tilt the substrate of the single-layer polystyrene bead template obtained in step 8 by 4°, deposit Ag 50nm, after the Ag deposition is completed, reverse Rotate the su...

Embodiment 3

[0052] A dynamically reversible adjustable bichiral nanostructure, the bottom surface of the structure is L-shaped, the short side of the L-shape is a metal material, and the thickness is 60nm; the long side of the L-shape is a four-layer structure, the bottom layer is a metal material, the thickness The metal material is a gas-sensitive metal material with a thickness of 60nm, and the gas-sensitive metal material is an isolation layer with a thickness of 5nm; the upper layer of the isolation layer is a catalytic layer with a thickness of 5nm.

[0053] In this embodiment, the metal material is Au; the gas-sensitive metal material is a lanthanum-nickel alloy; the isolation layer is La; and the catalytic layer is Pd.

[0054] The preparation method is the same as the preparation method in Example 1, the difference is only in step 9: tilt the substrate of the single-layer polystyrene bead template obtained in step 8 by 4°, deposit Au 30nm, and after the gold deposition is complete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com