Preparation device and method for recycled paper

A preparation device and technology for recycled paper, which are applied in pulp beating/refining methods, papermaking, and papermaking machines, etc., can solve the problems of high energy consumption, resource outflow, low waste water and environmental protection treatment capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

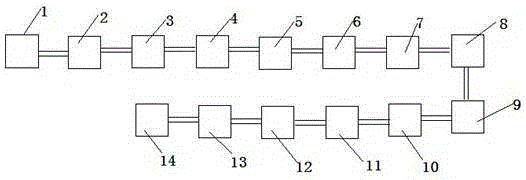

[0015] Such as figure 1 As shown, a production device for recycled paper, the pulper 1 is sequentially connected with the impurity separator 2, high-consistency slag remover 3, fiber separator 4, outflow pressure slot screen 5, low-concentration desander 6, The multi-disc thickener 7, the refiner 8, the height adjustment box 9, the front screen 10, the headbox 11, the fourdrinier mesh surface 12, the squeezer 13 and the dryer 14 are connected.

[0016] The fiber separator 4 includes a first-stage fiber separator and a second-stage fiber separator.

[0017] The low-concentration desander 6 includes three sections of low-concentration desander.

[0018] The press 13 includes a vacuum couch roll and a blind hole press roll with two large rolls.

[0019] The tailing end of the outflow pressure slot screen 5 is connected with the second stage outflow pressure slot screen through a pipeline.

[0020] The pulp and residue outlet end of the front screen 10 communicates with the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com