A kind of processing method of machine-harvested fresh-leaf floral-scented black tea

A processing method and fresh leaf technology are applied in the processing field of machine-picked fresh-leaf floral black tea, which can solve the problems of large proportion of finished tea and tea, low product value, incomplete product, etc. Unique style, rich and fresh effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

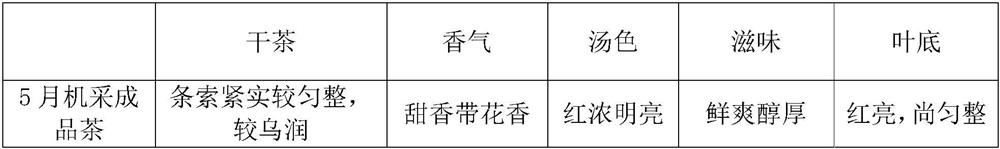

Embodiment 1

[0045] Implementation location: Enshi Qingjiang Tea Industry Co., Ltd., implementation time: May 2016, specific implementation methods:

[0046] 1. Tea tree buds and leaves mechanically composed of one bud and two leaves accounted for 50%, mechanically picked fresh leaves without dew or rain in the afternoon, lightly picked by a single tea picker, machine-picked fresh leaves, buds and leaves mechanically composed of complete leaves accounted for 57%, Single buds account for 8%, single leaves account for 30%, and old stems and impurities account for 5%.

[0047] 2. The fresh leaves collected by machine are returned to the factory in time, spread thinly on the drying mat, and sun-dried in the evening sun for 15 minutes, the weight of the green tea is reduced by 13%, the leaf color is dark green, the tea stalk is soft, and the green smell gradually disappears , the aroma is getting stronger.

[0048] 3. Move the sun-dried green leaves to the room in time, and let it cool for 1.5...

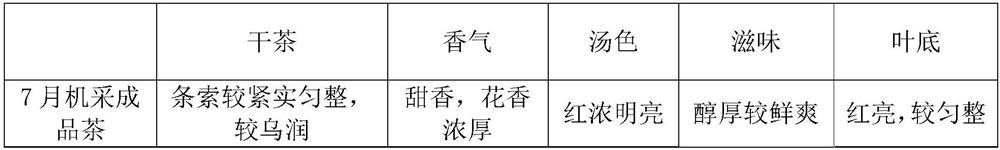

Embodiment 2

[0061] Implementation location: Tea Research Institute of Enshi Academy of Agricultural Sciences, implementation time: July 2016, specific implementation methods:

[0062] 1. Tea tree buds and leaves mechanically composed of one bud and two leaves accounted for 60%, mechanically picked fresh leaves without dew or rain in the afternoon, lightly picked by a single tea picker, machine-picked fresh leaves, buds and leaves mechanically composed of complete leaves accounted for 68%, , single leaves account for 25%, old stems and impurities account for 7%.

[0063] 2. The fresh leaves harvested by machine should be returned to the factory in time and spread thinly indoors. In the evening, move the tea greens to the sun for drying. After drying for 10 minutes, the tea greens will lose 15% of their weight. Disappears, the aroma is stronger.

[0064] 3. Move the sun-dried green leaves to the room in time, and let it cool down for 80 minutes.

[0065] 4. Turn over the green tea lightly...

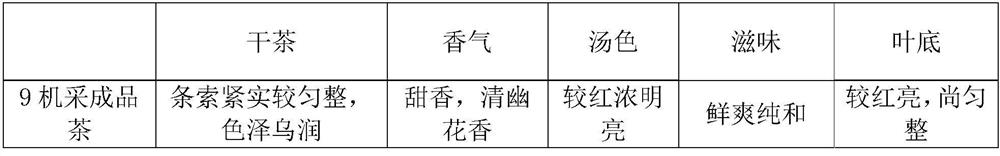

Embodiment 3

[0077] Implementation location: Lichuan, implementation time: September 2016, specific implementation methods:

[0078] 1. Tea tree buds and leaves mechanically composed of one bud and two leaves accounted for 70%. Mechanically picked fresh leaves without dew or rain in the afternoon. Two-person tea picking machines were used for light picking. Machine-picked fresh leaves accounted for 72% of complete leaves. Leaf leaves account for 20%, old stems and impurities account for 8%.

[0079] 2. Machine-picked fresh leaves are returned to the factory in time for thinning, and in the evening, move the tea leaves to the sun for drying. After drying for 15 minutes, the tea leaves will lose 10% of their weight. The leaves will be dark green, the tea stems will be softer, and the green smell will disappear Strong aroma.

[0080] 3. Move the sun-dried green leaves to the room in time, and let it cool down for 60 minutes.

[0081] 4. Turn over the green tea lightly for the first time by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com