Heating plate horizontal measurement tool structure and measurement method

A technology of level measurement and measurement method, applied in the direction of mechanical roughness/irregularity measurement, etc., can solve problems such as difficult operation and complicated measurement method, and achieve the effect of increasing accuracy, simple operation method and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

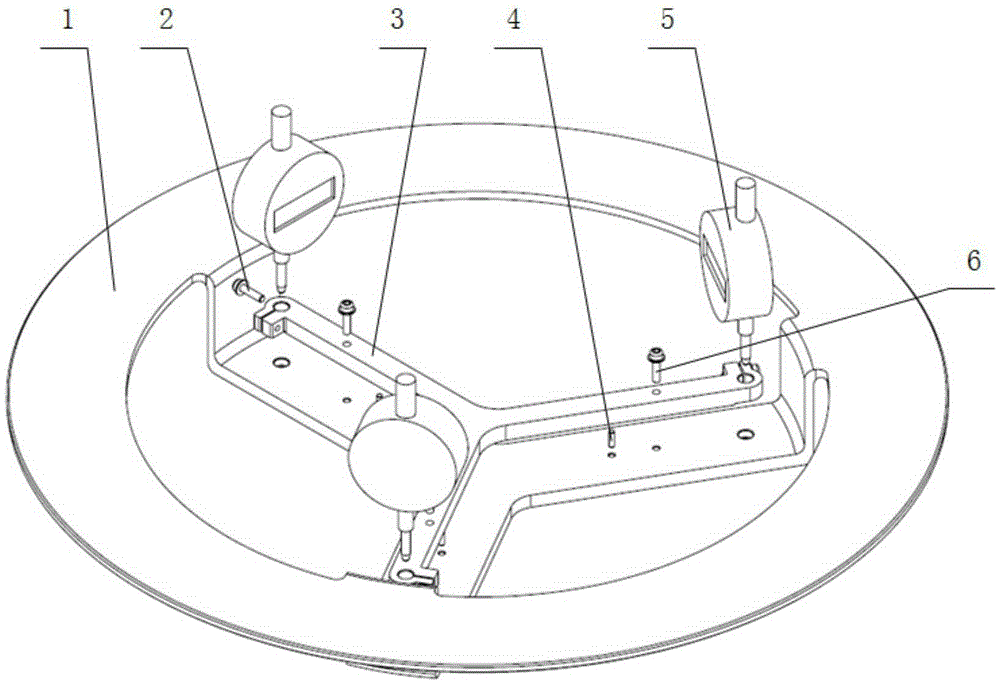

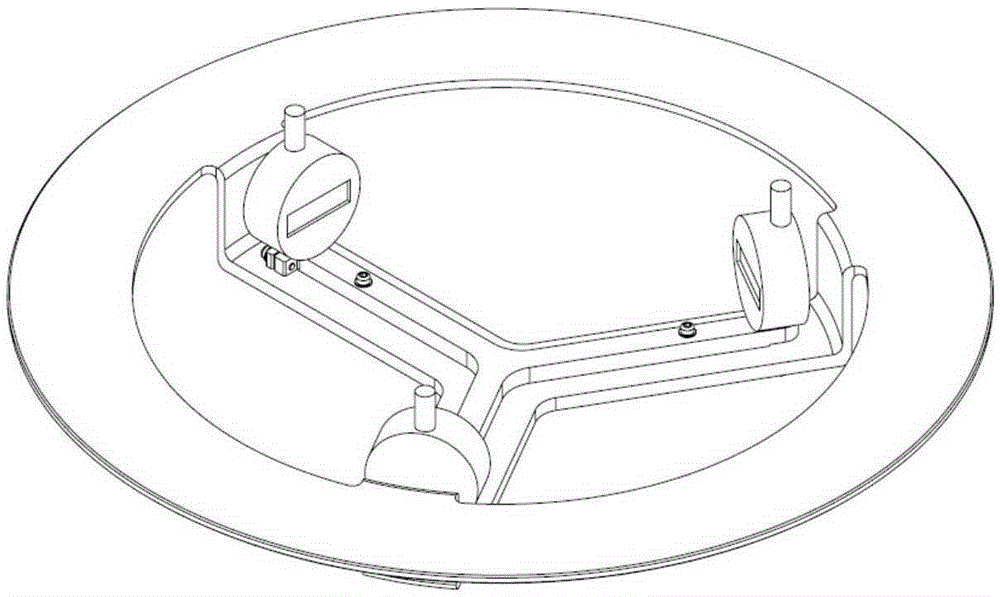

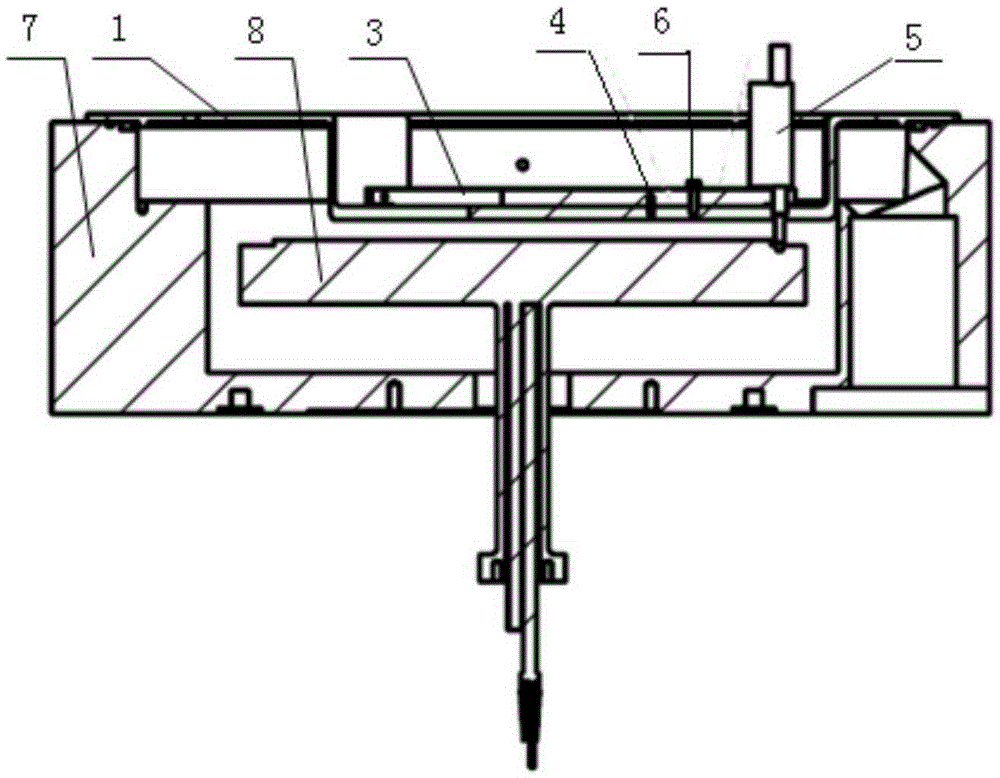

[0017] refer to Figure 1-3 , The heating plate level measurement tooling structure, including: positioning base 1, fastening digital dial gauge bolt 2, fixing frame 3, positioning pin 4, fastening bolt 6 and digital display dial gauge 5. The positioning base 1 is placed on the reaction chamber, and the lower surface of the disc of the positioning base 1 coincides with the positioning reference on the reaction chamber, so that the reference moves down to the positioning holes of the three dial gauges of the positioning base 1 . The dial gauge positioning hole of the positioning base 1 can ensure that the three digital display dial gauges 6 are measured on the same horizontal plane, and are evenly distributed on the surface of the heating plate at an angle of 120°. The fixing frame 3 is placed on the positioning base 1 through the positioning pin 4 , and the fixing frame 3 is fastened on the positioning base 1 with fastening bolts 6 . The digital display dial indicator 5 is pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com