Bearing tooth surface lubricating device for wind generating set

A technology for wind turbines and lubricating devices, which is applied in the directions of wind turbines, wind power generation, gear lubrication/cooling, etc. It can solve the problems that lubricant cannot be added to the working parts of the gears, reduce the work intensity of manual lubricant application, etc., and achieve enhanced Effects of life, wear reduction, and friction increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

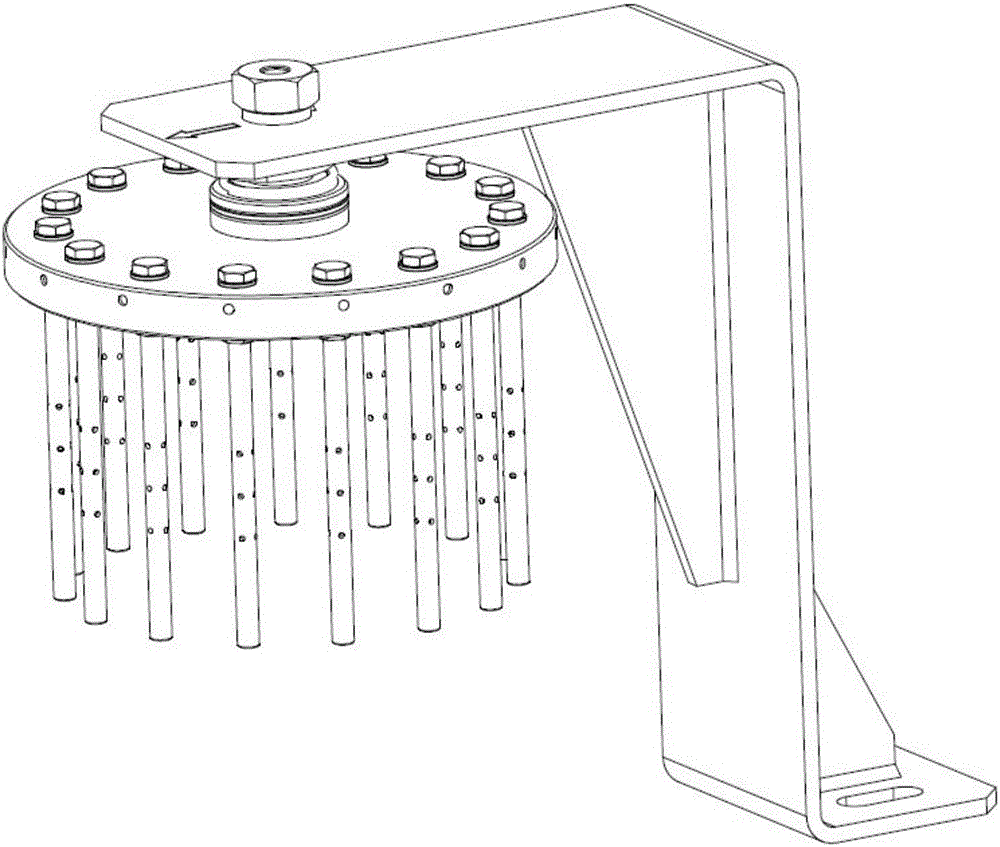

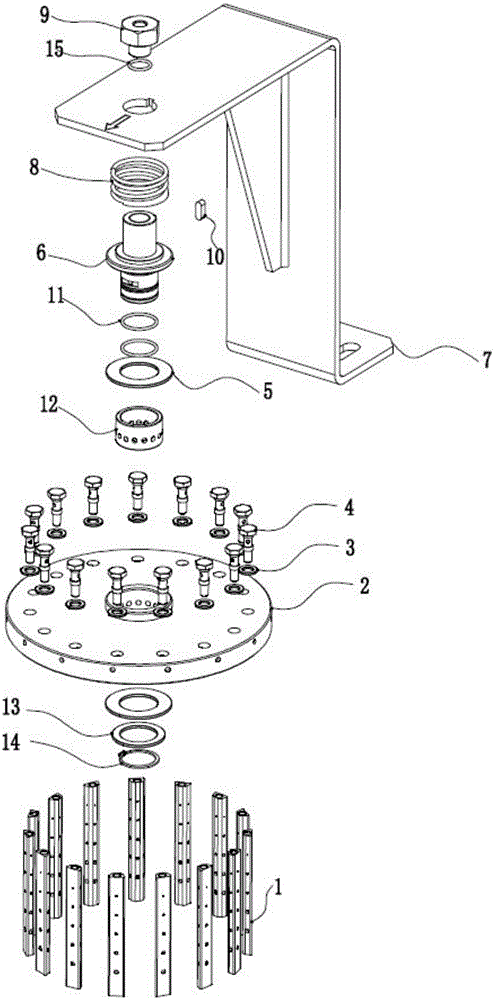

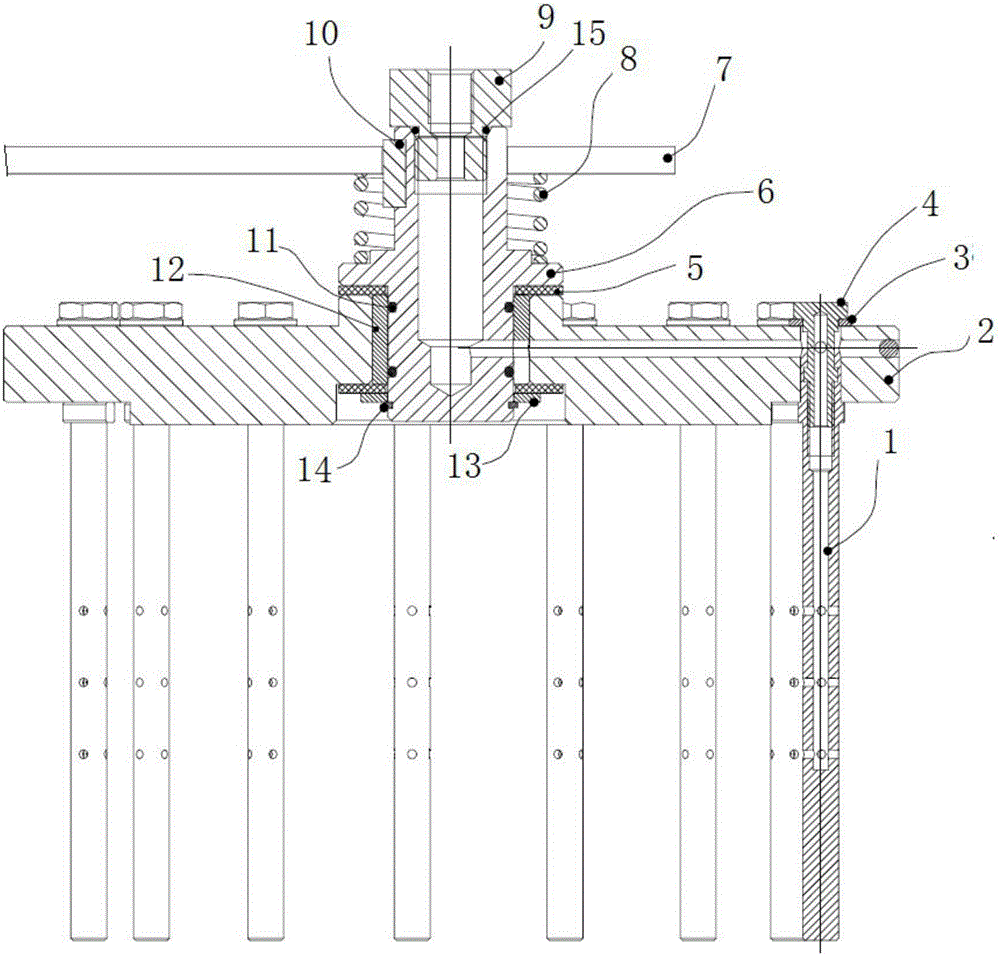

[0027] like Figure 1 to Figure 6 As shown, a bearing tooth surface lubricating device 40 for a wind power generating set is used for lubricating the meshing part of the pitch ring gear, installed on the driving gear, and rotates together with the driving gear teeth ( Image 6 ).

[0028] like Figure 1 to Figure 3 As shown, the device includes an oil spreader 1, an oil separator 2, a sealing gasket 3, a connecting bolt 4, a gasket 5, a shaft 6, a fixing bracket 7, a spring 8, a connecting joint 9, a flat key 10, and an o-ring A11, tin bronze sleeve 12, washer 13, shaft retaining ring 14, O-ring B15.

[0029] The oil pan 2 is connected to the fixed bracket 7 through the shaft 6, the upper part of the shaft 6 is fixedly connected with the fixed bracket 7 through the flat key 10, the upper end of the shaft 6 and the connecting joint 9 are sealed and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com