Colored flame-retardant polyester-cotton fabric and preparation method thereof

A technology for colored polyester-cotton fabrics and polyester-cotton fabrics, applied in the field of colored flame-retardant polyester-cotton fabrics and their preparation, can solve the problems of rare products and high cost, achieve easy operation, ensure safety, and ensure that raw materials are environmentally friendly sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

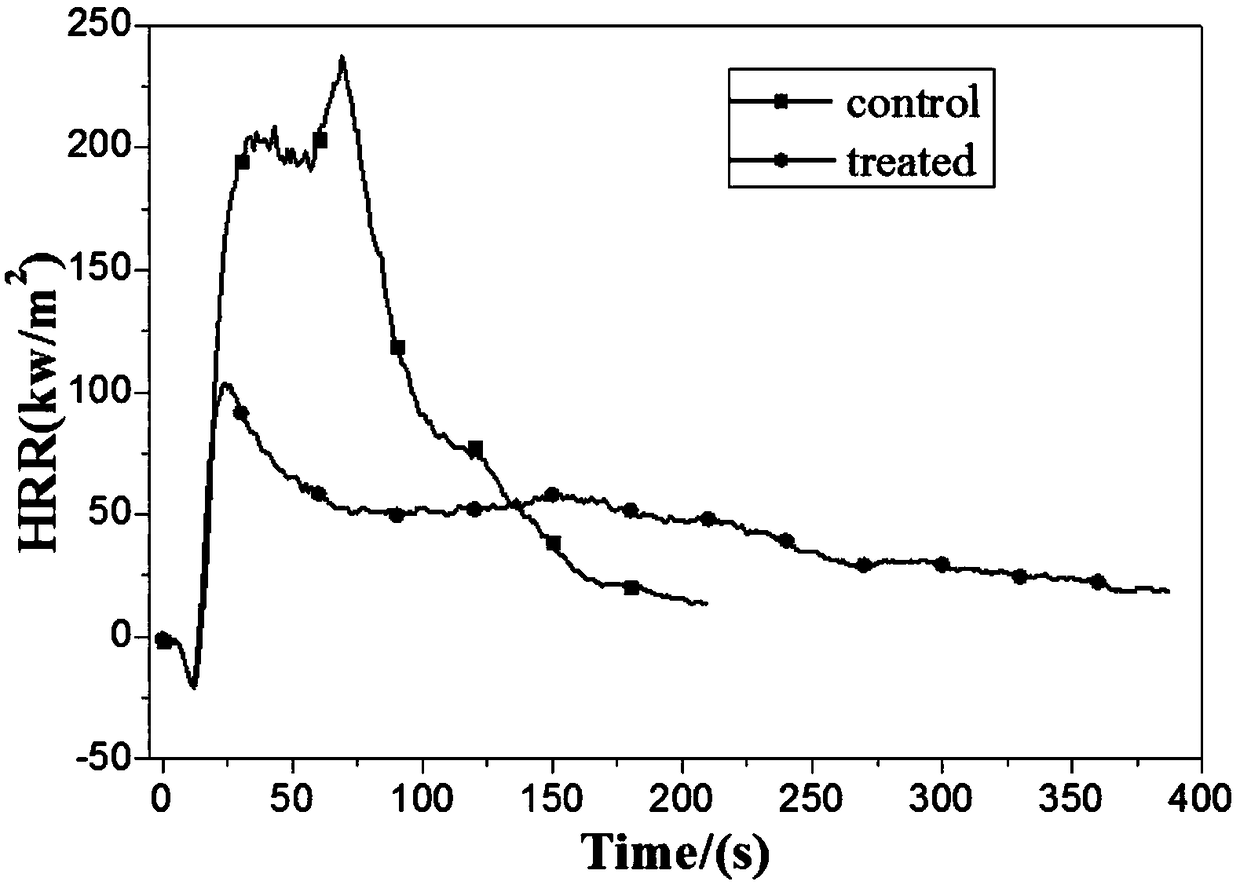

[0031] Soak 65 / 35 polyester-cotton fabric in 2g / L dopamine aqueous solution, treat at 35°C for 24 hours, take out the fabric, wash with water, and dry to obtain light brown polyester-cotton fabric. Prepare a sodium phytate aqueous solution with a mass fraction of 1.5%, and adjust the pH value to 2. Immerse the dopamine-treated light brown polyester-cotton fabric in the above sodium phytate aqueous solution, take it out after soaking for 15 minutes, rinse, and dry; Take it out after 5 minutes, rinse and dry. Thereafter, alternately immerse in sodium phytate aqueous solution and chitosan aqueous solution for 5 minutes each, repeat dipping, rinsing, and drying, and do a total of 15 alternate dippings to obtain colored flame-retardant polyester-cotton fabrics. According to the oxygen index method of GB / T5454-1997 textile combustion performance test, the oxygen index of the colored flame-retardant polyester-cotton fabric is 28.6%, while the oxygen index of the 65 / 35 polyester-cott...

Embodiment 2

[0033] Soak 45 / 55 polyester-cotton fabric in 1.5g / L dopamine aqueous solution, treat at 35°C for 24 hours, take out the fabric, wash with water, and dry to obtain light brown polyester-cotton fabric. Prepare a sodium phytate aqueous solution with a mass fraction of 2%, adjust the pH value to 3, immerse the dopamine-treated light brown polyester-cotton fabric in the above-mentioned sodium phytate aqueous solution, soak for 15 minutes, take it out, rinse, and dry. Then immerse in a chitosan solution with a pH value of 5 and a mass fraction of 1%, take it out after 5 minutes of immersion, rinse, and dry, then alternately immerse in sodium phytate aqueous solution and chitosan aqueous solution for 5 minutes each, repeat dipping and rinsing. Washing, drying, and doing 20 alternate impregnations altogether, obtain colored flame-retardant polyester-cotton fabric. According to the oxygen index method of GB / T5454-1997 textile combustion performance test, the oxygen index of the colored...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com