A strain of Bacillus licheniformis resistant to high temperature degradation of crude oil to produce emulsifier and its application

A technology of Bacillus licheniformis and a biological emulsifier, which is applied in the fields of energy biotechnology and environmental biology, can solve the problem of not many bacterial species, and achieves improved colloid content, high emulsifying ability and temperature resistance, and improved crude oil recovery. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

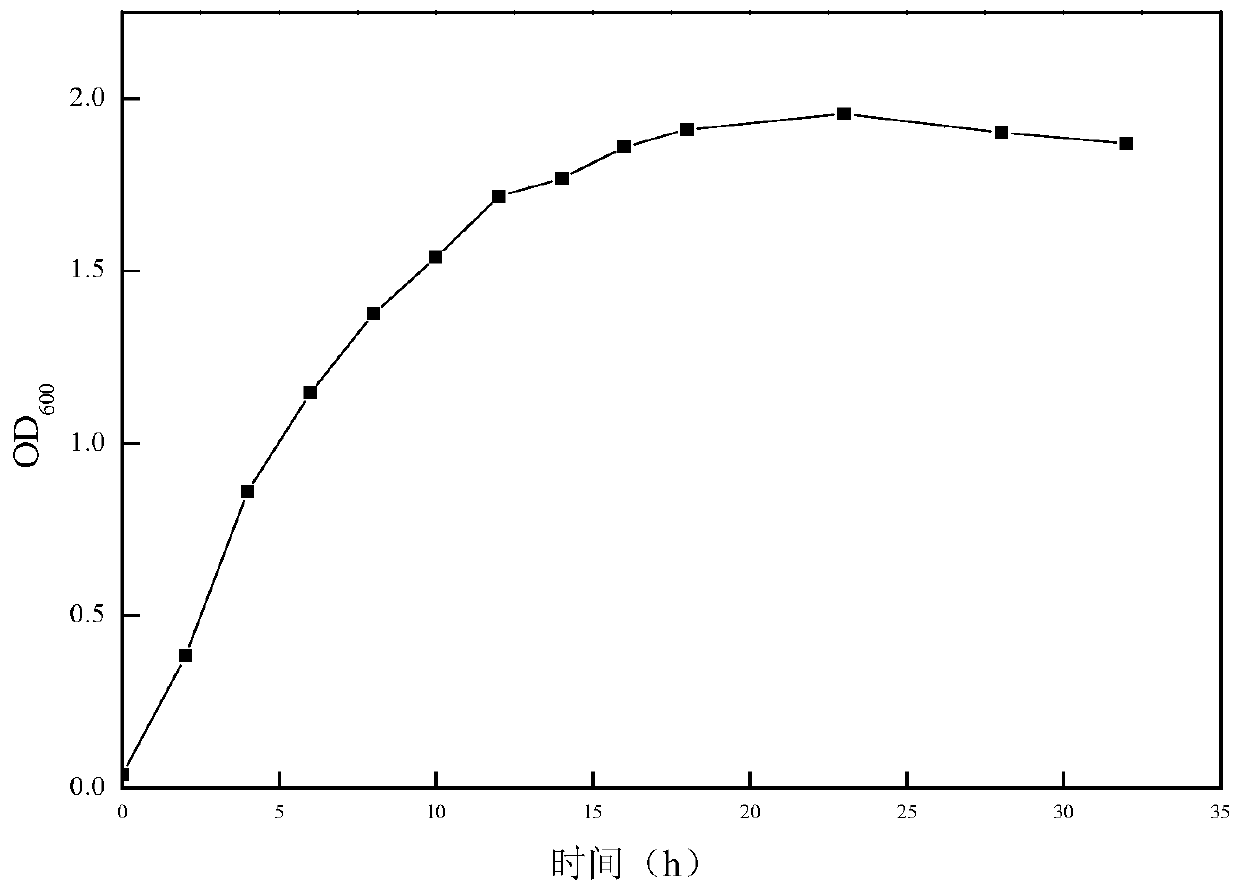

[0046] Screening, isolation, identification and growth curve determination of the high temperature resistant oil production bacteria T6189 of the present invention

[0047] The first step: Screening of high temperature resistant oil production bacteria T6189

[0048] The screening method of high temperature-resistant oil production bacteria T6189: according to the crude oil inorganic salt medium (its composition is: NaNO 3 10g / L, Na 2 MO 4 0.08g / L, FeSO 4 0.12g / L, MgSO 4 0.2g / L, CaCl 2 0.12g / L, KH 2 PO 4 1.0g / L, (NH 4 ) 2 HPO 4 1.0g / L, crude oil (derived from Xinjiang T6189 well production fluid) 2% (V / V), sucrose 0.2‰ (W / V) (the amount of crude oil and sucrose added is based on 100% of the inorganic salt medium); pH value Prepare medium for 7.0-7.2) formula, wherein add 0.2‰ sucrose in the medium to quickly activate the bacteria so that the screening process can be carried out quickly.

[0049] The experimental steps are as follows:

[0050] (1) Pack the pre...

Embodiment 2

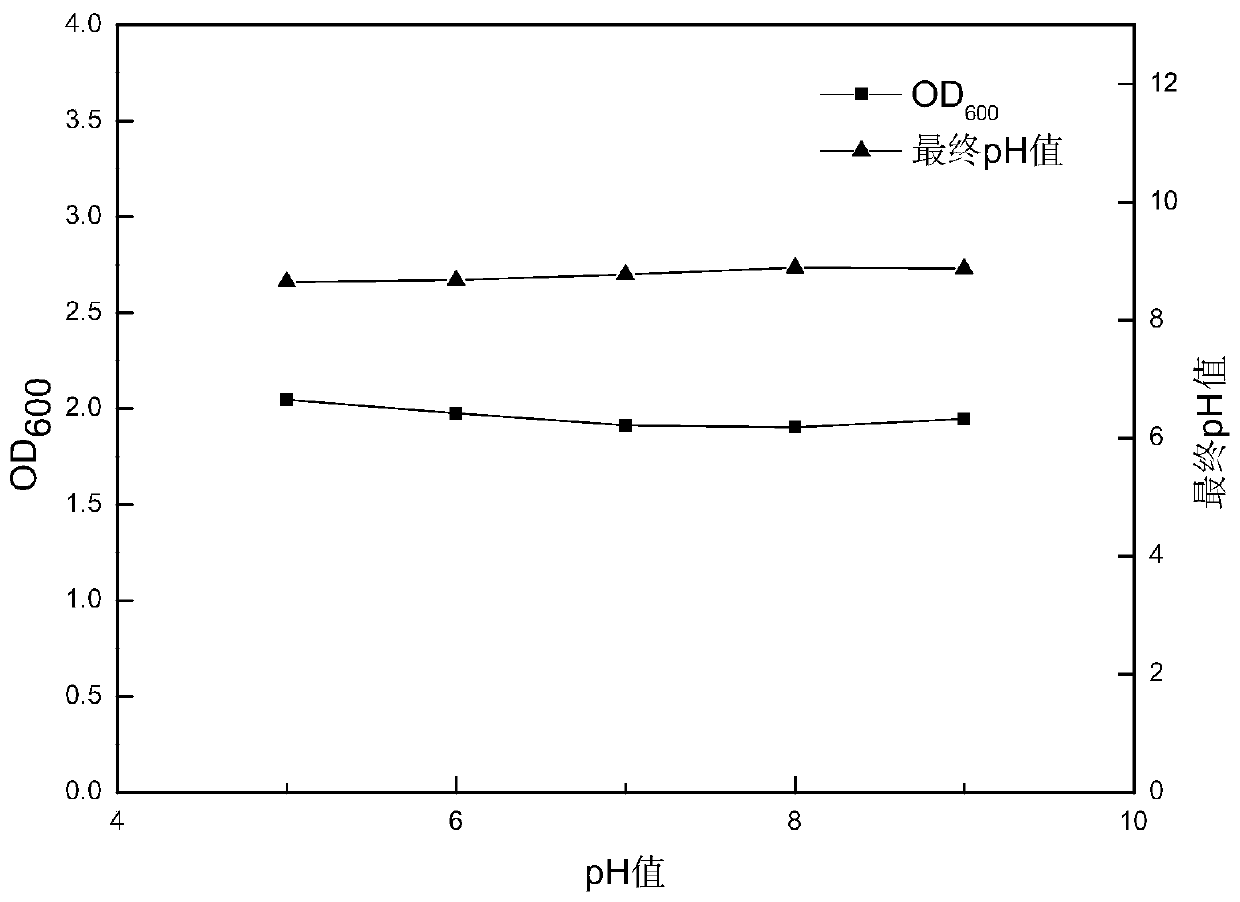

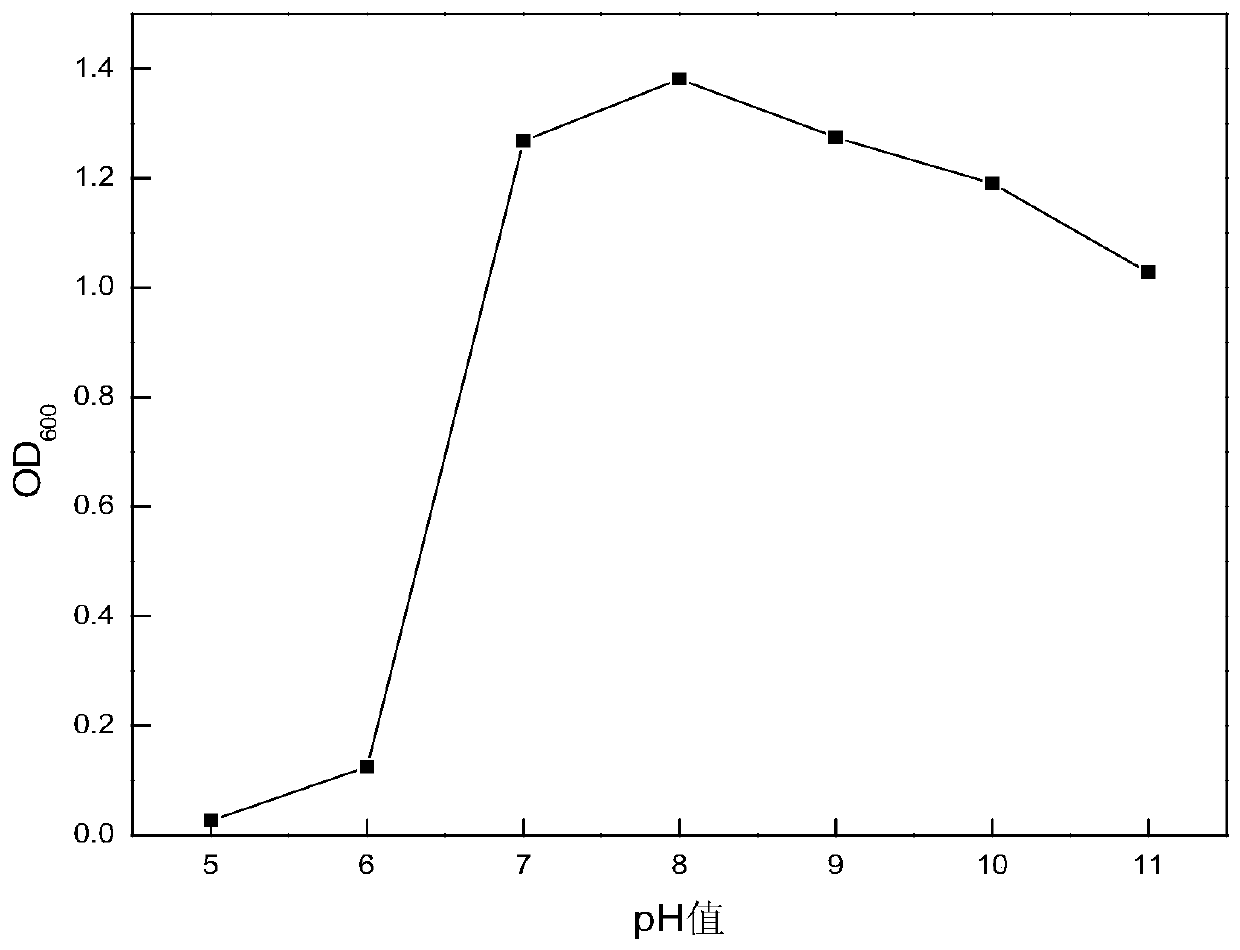

[0071] Effects of Different pH Values, Temperatures and Salinity on the Growth of Thermostable Oil Production Bacteria T6189

[0072] (1) Effect of pH value on the growth of the bacterium: ① prepare LB liquid culture medium, pack in 150mL Erlenmeyer flasks, and the volume of each bottle is 100mL; use 1mol / L hydrochloric acid and 1mol / L sodium hydroxide to adjust each The pH values in the bottle are 5, 6, 7, 8 and 9 respectively; ② Sterilize in a high-temperature and high-pressure sterilizer, and insert the seed liquid (that is, the bacterial liquid after LB medium activates the T6189 strain) according to the inoculum amount of 2wt% , and then cultivated at 55°C and 150rpm for 48 hours; ③ After the cultivation, take 4mL of the culture solution in a centrifuge tube, centrifuge to wash the precipitate and suspend the bacteria with an equal volume of distilled water, measure its absorbance under the condition of 600nm in a UV spectrophotometer and observe its Bacterial concentra...

Embodiment 3

[0077] Metabolic characteristics of oil production bacteria T6189 with high temperature tolerance to crude oil

[0078] Step 1: Microbial metabolism and extraction separation of crude oil

[0079] The crude oil used in the present invention is respectively from the oil samples of Well 4001, Well 4024, Well 4027, Well 4032 and Well 4045 in Henan Oilfield, wherein the oil samples of Well 4027 are liquid at normal temperature, and the oil samples of other oil wells are all solid at normal temperature . The specific experimental steps are as follows:

[0080] (1) Microbial metabolism of crude oil: 1. Prepare the medium according to the inorganic salt medium, add 0.2wt% sucrose in the medium as a rapid microbial activator, and then add 0.5wt% of different crude oils to each 100mL culture medium Sealed in a 150mL Erlenmeyer flask, and sterilized at 121°C for 15min; ②Take out each Erlenmeyer flask containing different crude oils and cool them in an ultra-clean workbench, and inocul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com