Nylon sheath material for wires and cables and preparation method thereof

A nylon sheath material, wire and cable technology, applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of restricting the expansion and application of wire and cable fields, increasing the production burden of factories, and difficult high-speed production, etc., to achieve excellent chemical corrosion resistance capacity, increased production burden, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

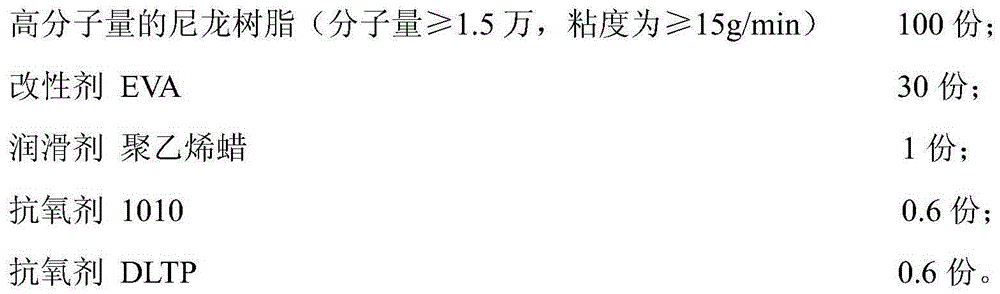

[0041] In the cable material formula, the name of each component and the proportion of each component by weight are as follows:

[0042]

[0043] Components Select the raw materials for each component according to the stated ratio, fully mix the accurately weighed resin and additives in a high-speed mixer at a speed of 100-1500 rpm, and the mixing temperature of the high-speed mixer is 25-75°C. The mixing time is 5-20min. Extrude and granulate in a feed extrusion granulation mixing type twin-screw extrusion granulator, the extrusion temperature of the twin-screw extruder is 220-280 ° C, the temperature setting of the twin-screw extruder It is: feeding section 220-240°C, mixing section 230-250°C, extrusion granulation section 240-270°C, head part 255-280°C. Drying after granulation, the drying temperature is 60-95° C., and the drying time is 1-3 hours, and the pellets for cables are obtained. The composition and weight ratio of the raw material components are shown in Tabl...

Embodiment 2

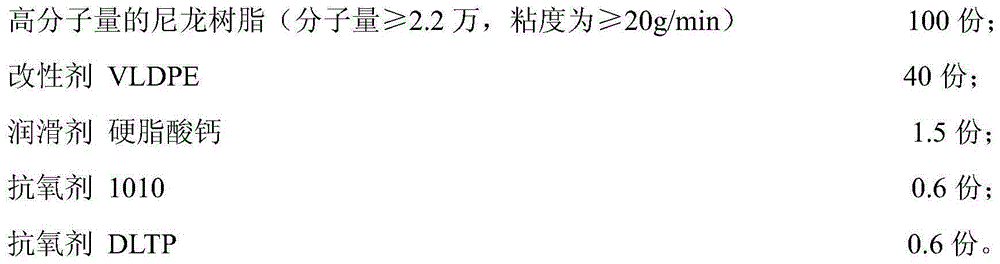

[0045] In the cable material formula, the name of each component and the proportion of each component by weight are as follows:

[0046]

[0047] Components Select the raw materials for each component according to the stated ratio, fully mix the accurately weighed resin and additives in a high-speed mixer at a speed of 500-1000rpm, the mixing temperature of the high-speed mixer is 50°C, and the mixing time 15min. Extrude and granulate in a feeding extrusion granulation mixing type twin-screw extrusion granulator, the extrusion temperature of the twin-screw extruder is 230-270 ° C, the temperature setting of the twin-screw extruder It is: 230°C in the feeding section, 240°C in the mixing section, 260°C in the extrusion granulation section, and 270°C in the head part. Drying after granulation, the drying temperature is 80° C., and the drying time is 2 hours, to obtain granules for cables. The composition and weight ratio of the raw material components are shown in Table 1. ...

Embodiment 3

[0049]In the cable material formula, the name of each component and the proportion of each component by weight are as follows:

[0050]

[0051]

[0052] Processes such as mixing and extrusion granulation are the same as in Example 1. The composition and weight ratio of the raw material components are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com