A kind of olefin polymerization catalyst system and its application

An olefin polymerization and catalyst technology, applied in the field of olefin polymerization, can solve problems such as difficulties, and achieve the effects of simple polymerization method, high polymerization activity, and improved hydrogen modulation sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

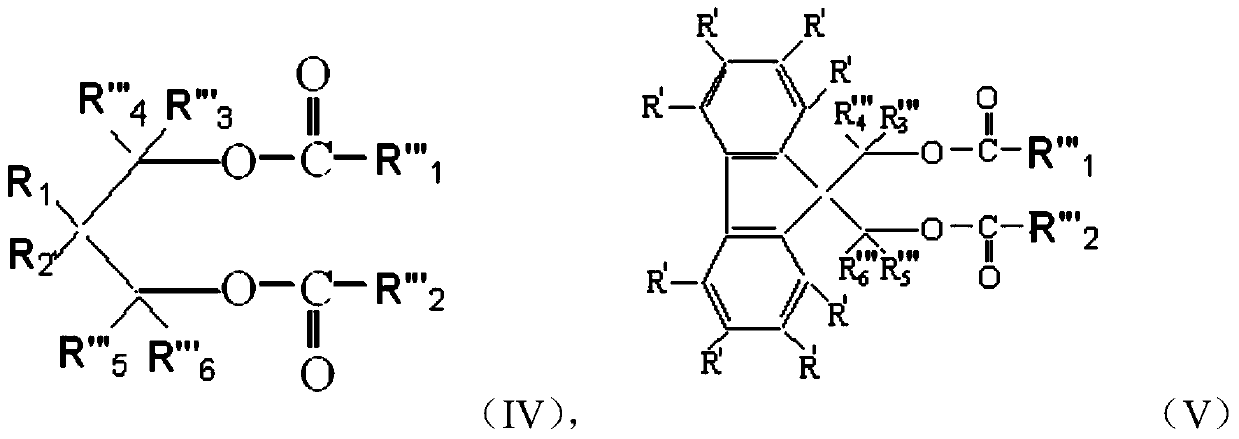

Image

Examples

Embodiment approach

[0087] According to a specific embodiment of the present invention, the specific preparation method of the magnesium halide alkoxide carrier includes: mixing anhydrous magnesium halide and a lower alcohol, heating up the reaction to generate a magnesium halide alkoxide melt, and the reaction temperature is At 90-140°C, the dispersion medium is subjected to high shear and placed in a cooled inert medium to form spherical magnesium halide alcoholate particles, which are washed and dried to obtain a spherical carrier. The high shear effect can be obtained by conventional methods, such as high-speed stirring method (such as CN1330086), spray method (such as US6020279), supergravity rotating bed (such as CN1580136A) and emulsifier method (CN1463990A). The dispersant system uses hydrocarbon inert solvents, such as kerosene, white oil, silicone oil, paraffin oil, petrolatum, etc. The cooling medium is selected from pentane, hexane, heptane, petroleum ether, raffinate and the like.

[0...

preparation example

[0101] Add 100ml of titanium tetrachloride to a 300ml glass reaction flask with stirring that has been fully replaced by high-purity nitrogen, cool to -20°C, add spherical magnesium chloride alkoxide (see Chinese Patent CN1330086A for the preparation method), and slowly raise the temperature to 110 ℃, add 2.5mol of diol ester compound and 3.9mmol of carboxylate compound during the heating process, after constant temperature at 110°C for 0.5h, filter out the liquid, add titanium tetrachloride for two treatments, and then wash with hexane five times. After vacuum drying, a titanium-containing solid catalyst component A is obtained.

Embodiment

[0103] According to the components in Examples 1-14 and Comparative Examples 1-4 in Table 1, the polymerization reaction of propylene was carried out with reference to the following conditions.

[0104] In a 5-liter autoclave, purged with a nitrogen stream at 70°C for 1 hour, and then replaced the polymerizer with gas phase propylene three times, and introduced 5 ml of alkyl aluminum compound (the concentration of triethyl aluminum is 0.5 mmol / ml), 1ml of hexane solution of the external electron donor (the concentration of the external electron donor is 0.1mmol / ml), 10ml of anhydrous hexane and 8-12mg of titanium-containing solid catalyst component A. Close the autoclave, introduce a certain volume of hydrogen (at 25°C, normal pressure) (L) and 1.0-1.2Kg of liquid propylene; quickly raise the temperature in the scalp to 70°C under stirring. After the polymerization reaction at 70°C for 1 hour, the stirring was stopped to remove the unpolymerized propylene monomer, and the polymer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com