Tooth shape grinding device for connecting rods

A grinding device and tooth type technology, which is applied in the direction of grinding devices, grinding drive devices, grinding machine tools, etc., can solve the problems of large grinding workload, high labor load intensity, and high grip point, so as to shorten the repair cycle and reduce manpower Consumption, the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

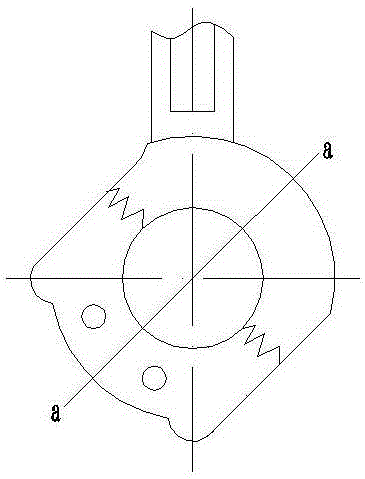

Image

Examples

Embodiment Construction

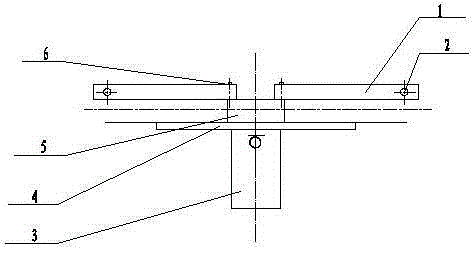

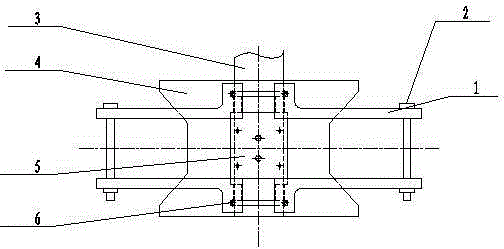

[0014] Such as figure 2 , 3 As shown, the present invention comprises a fastening plate 1, an I-shaped plate 4, and a cylinder 5; the cylinder 5 is fixed on the connecting rod between the upper and lower sides of the I-shaped plate 4 with bolts, and the four fastening plates 1 are respectively passed through the bolts 6 Fixed on the piston of the cylinder 5, the four fastening plates 1 are L-shaped respectively, and the bottom edges of every two L-shaped fastening plates 1 are fixed by bolts 6, and the four L-shaped fastening plates 1 form a frame Clamp the piston of the cylinder 5, and fix the fastening plate 1 on the piston of the cylinder 5 through the bolt 6. When the cylinder 5 is working, the reciprocating motion of the cylinder piston can drive the four fastening plates 1 along the I-shaped plate 4 The connecting rod between the upper and lower sides, that is, image 3 Reciprocating linear motion in the up and down direction of the center, screw holes are provided on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com