High-strength spheroidal graphite cast iron forging method

A ductile iron, high-strength technology, used in the manufacture of tools, forging/pressing/hammer devices, heating/cooling equipment, etc., can solve the problem of reducing the quality and use quality of ductile iron products, casting problems are not well solved, waste products. The problem of high loss rate can achieve the effect of avoiding poor spheroidization, good application prospects and refining internal grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

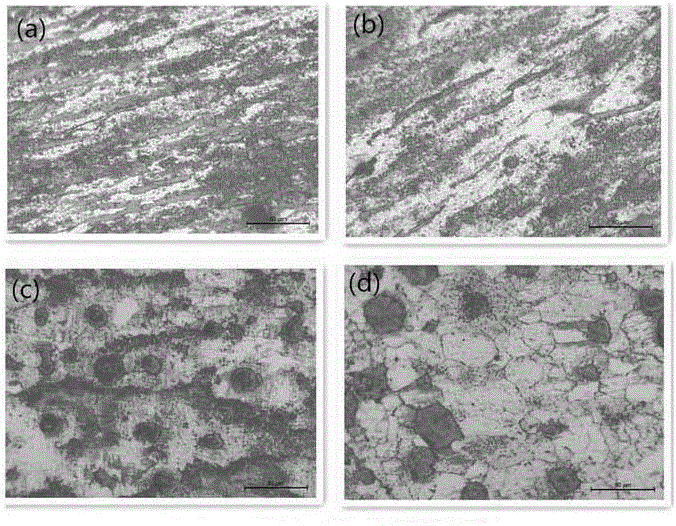

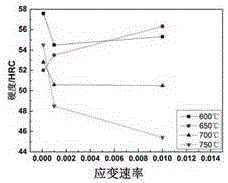

[0025] Take a cylindrical ductile iron sample with a size of φ10×15mm, and keep it at 550°C for 30 minutes. Raise the temperature by 5°C; then forge and shape. The initial forging temperature is 550°C and the final forging temperature is 500°C. During forging, the deformation of a single forging is controlled to be 70%, and the strain rate is 0.0001 / s. Natural cooling in the air.

Embodiment 2

[0027] Take a cylindrical ductile iron sample with a size of φ50×75mm, and keep it at 590°C for 54 minutes. Raise the temperature by 12°C, and increase the temperature by 7°C per minute in the range of 500-590°C; then forge and shape, the initial forging temperature is 586°C, and the final forging temperature is 540°C. The weight is 60%, the strain rate is 0.005 / s, and it is naturally cooled in the air after forging.

Embodiment 3

[0029] Take a cylindrical nodular cast iron sample with a size of φ100×150mm, and keep it at 635°C for 60 minutes. The temperature is raised by 15°C, and the temperature is raised by 9°C per minute in the range of 500-635°C; then the double-sided alternate forging method is used for forging and forming, the initial forging temperature is 630°C, and the final forging temperature is 600°C, and the single forging deformation is controlled during forging The amount is 40%, the total deformation of forging is 65%, the strain rate is 0.008 / s, and water cooling is carried out after forging.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com