Coil autoexcitation electromagnetic ultrasonic lamb wave transducer

An electromagnetic ultrasonic, transducer technology used in the direction of fluids that utilize vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

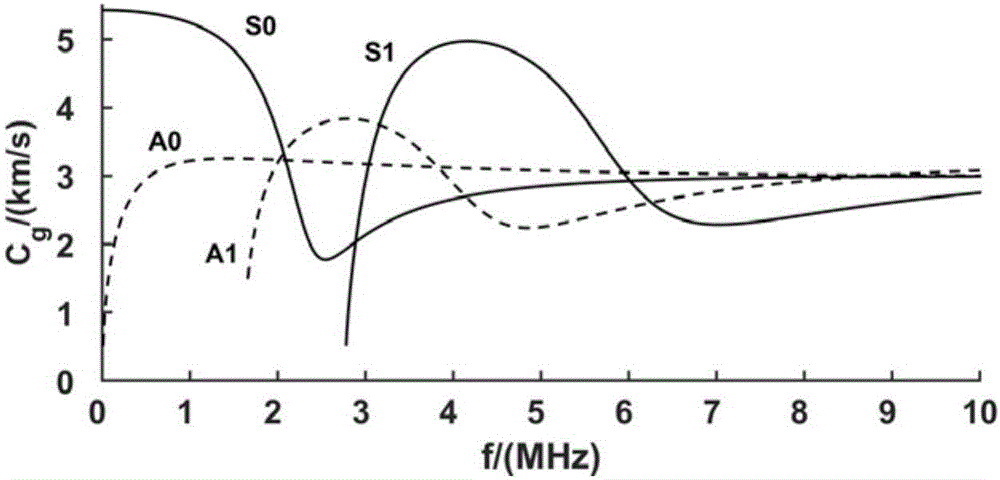

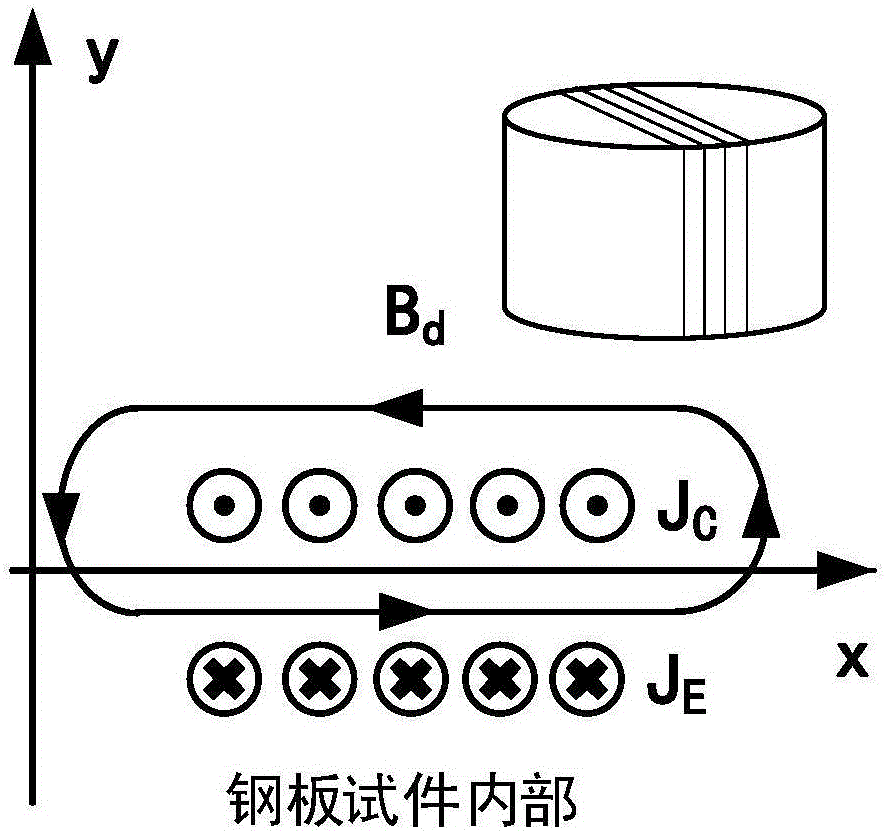

[0021] The self-excited transducer is designed as image 3 shown. image 3 The small picture in the upper right corner of the center shows the coil winding method of the self-excited transducer. A copper enameled wire with a diameter of 0.03mm to 2mm is selected for linear winding on a cylindrical plastic 3D printed plastic model. The diameter of the 3D printed model ranges from 10mm to 50mm. , the height range is 3mm to 50mm, and the number of coil winding turns is 3 to 15 turns. The product of the excitation pulse current frequency and the thickness of the ferromagnetic sheet is less than 1.5MHz·mm to ensure that only S 0 and A 0 Lambo. The energy conversion process is carried out between the coil and the ferromagnetic plate to be tested, such as image 3 shown. The x-axis represents the upper surface of the ferromagnetic sheet, the positive half-axis of the y-axis represents the air domain, and the negative half-axis of the y-axis represents the interior of the ferroma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com