Graphene oxide covalently bonded and coated magnetic nanoparticle composite material and preparation method thereof

A magnetic nanoparticle and composite material technology, applied in the field of graphene oxide covalent bond-coated magnetic nanoparticle composite material and its preparation, can solve the problems of composite material structure and performance influence, application value, adsorption performance decline and the like, Achieve the effect of excellent adsorption performance, structural improvement and adsorption regeneration performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

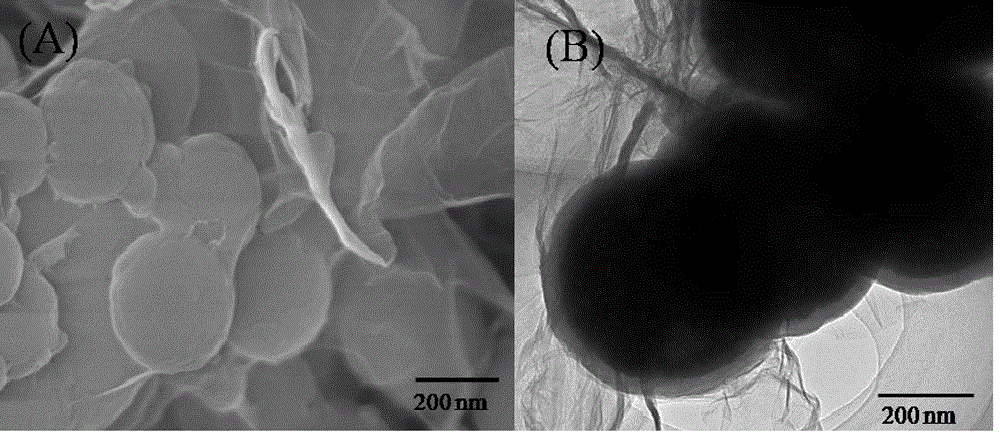

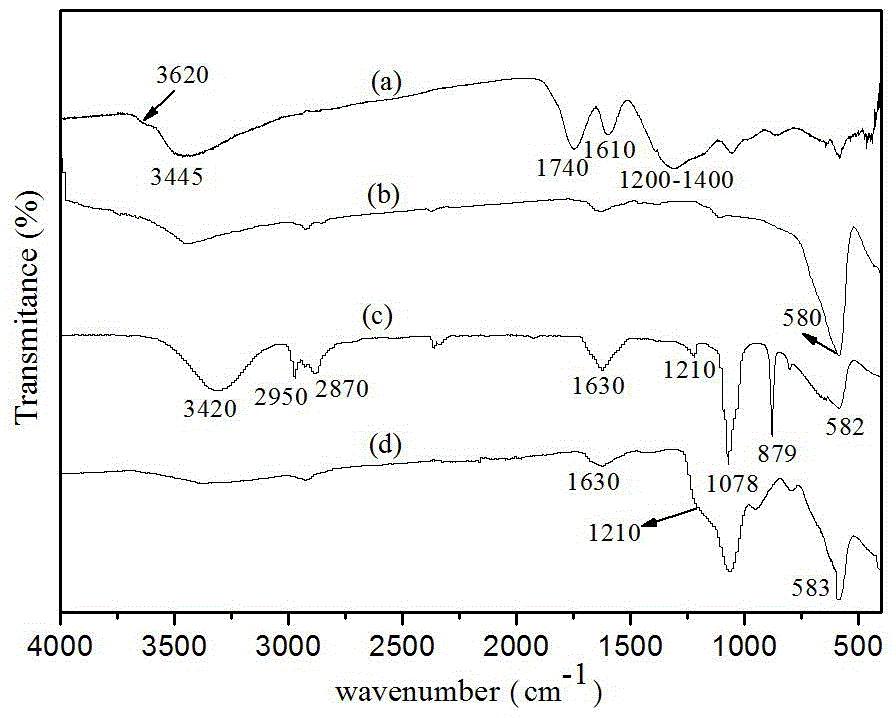

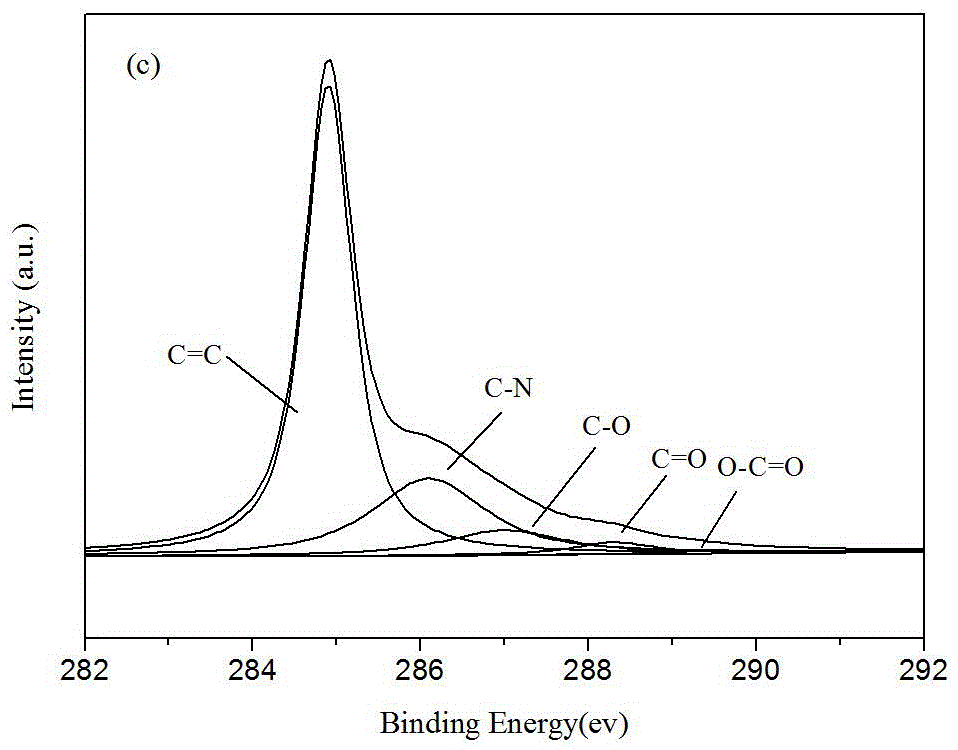

[0038] S1. Add 1.0 g of polyethylene glycol (PEG-4000) into 40 mL of ethylene glycol (EG), and stir magnetically for 30 minutes under heating in an oil bath at 80°C until PEG-4000 is completely dissolved. Weigh 1.35 g ferric chloride hexahydrate (FeCl 3 •6H 2 O), 3.6 g sodium acetate (NaAc 3H 2 O), add to the above dissolving solution, stir to make it dissolve completely, and add distilled water 5mL dropwise to the mixed solution during the dissolving process. Stirring was continued for 30 min until the mixture was completely dissolved, then transferred to a 100 mL stainless steel autoclave lined with polytetrafluoroethylene, reacted in a blast oven at 200 °C for 8 h, and cooled naturally to room temperature. Collected by centrifugation, washed several times with distilled water and absolute ethanol, and finally dried at 60°C for 6 hours to obtain Fe 3 o 4 Nanoparticles;

[0039] S2. Weigh 1.4g Fe 3 o 4 The nanoparticles were added to a four-neck flask containing 280 mL...

Embodiment 2

[0050] S1. Add 1.0 g of polyethylene glycol (PEG-4000) into 40 mL of ethylene glycol (EG), and stir magnetically for 30 minutes under heating in an oil bath at 80°C until PEG-4000 is completely dissolved. Weigh 1.35 g ferric chloride hexahydrate (FeCl 3 • 6H2O), 3.6 g sodium acetate (NaAc • 3H 2 O), add to the above dissolving solution, stir to make it dissolve completely, during the dissolving process, add distilled water H dropwise to the mixed solution 2 O 10mL. Stirring was continued for 30 min until the mixture was completely dissolved, then transferred to a 100 mL stainless steel autoclave lined with polytetrafluoroethylene, reacted in a blast oven at 200 °C for 4 h, and cooled naturally to room temperature. Collected by centrifugation, washed several times with distilled water and absolute ethanol, and finally dried at 60°C for 6 hours to obtain Fe 3 o 4 particle;

[0051] S2. Weigh 1.4g Fe 3 o 4 Sonicate for 15 min to disperse into a four-necked flask containing...

Embodiment 3~10

[0058] The preparation method of embodiment 3~6 is substantially the same as embodiment 1, difference is as follows:

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com