Shampoo special for coal mines

A shampoo and coal mine technology, applied in the field of shampoo, can solve the problems of susceptibility to skin diseases, severe skin damage, skin irritation, etc., achieve obvious moisturizing and moisturizing effects, reduce the number and time of bathing, and avoid skin irritation. damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

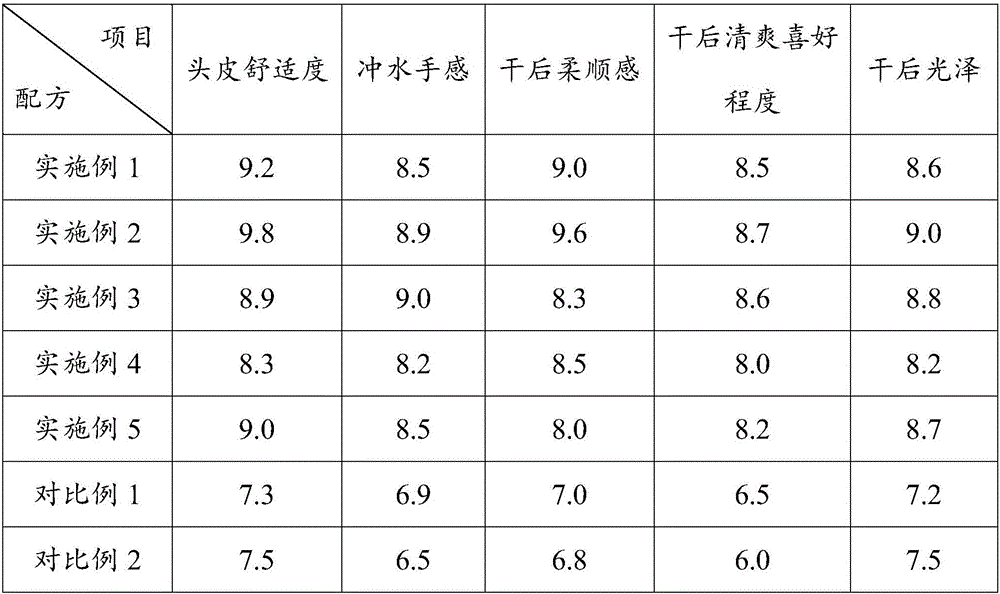

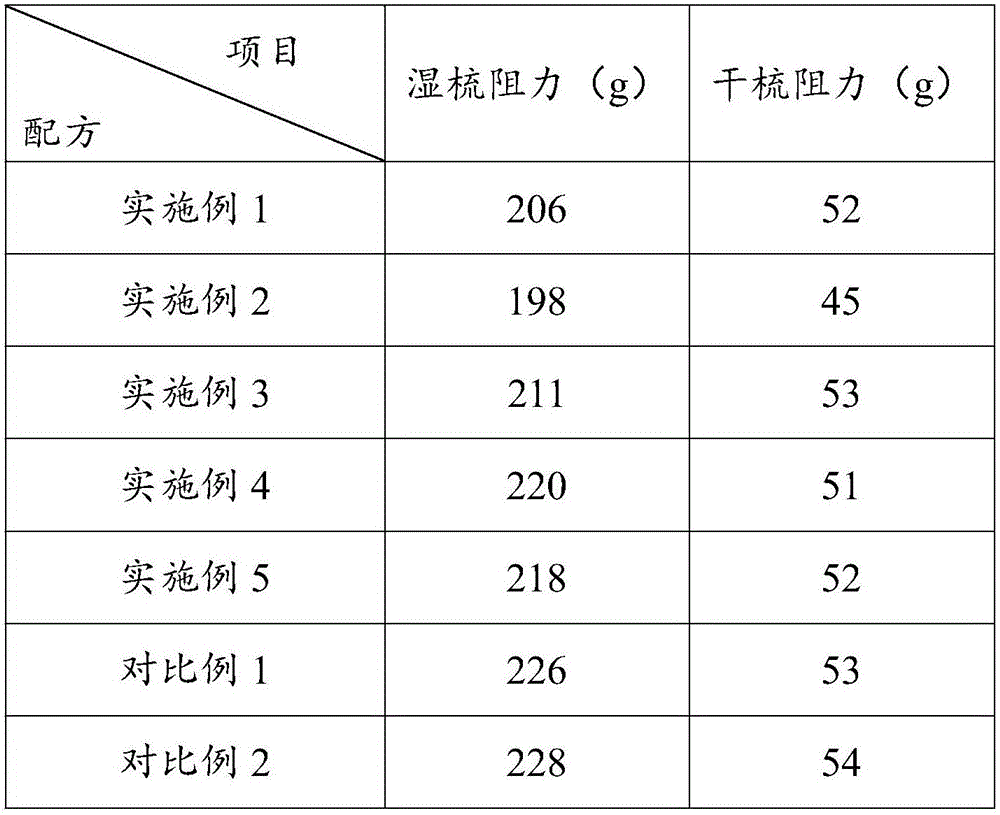

Examples

Embodiment 1

[0035] A special shampoo for coal mines, prepared according to the following method from the following raw materials in weight percent (%): under water bath conditions, 2.5% decyl glucoside, 8.5% sodium α-alkenyl sulfonate, methyl coconut oil Sodium taurate 2.0%, sodium laureth sulfate 10.0%, cocamidopropyl betaine 3.5%, coconut oil fatty acid diethanolamide 5.0% were dispersed in deionized water and ethylenediaminetetraacetic acid two by one Sodium 0.2%, heated to 80°C and stirred quickly; then sequentially added 0.25% guar gum, 2.5% PEG-7 glyceryl cocoate, 0.08% PEG-75 shea butter and 2.3% emulsified silicone oil to dissolve, And stir evenly; after cooling down to 45°C, add 0.35% hydantoin, 2.5% pearlescent paste, 1.0% sodium chloride, 1.5% citric acid and 0.15% essence for constant weight, adjust the pH value, and stir until uniform .

Embodiment 2

[0037] A special shampoo for coal mines, prepared according to the following method from the following raw materials in weight percent (%): under water bath conditions, 3.0% decyl glucoside, 10.0% sodium α-alkenyl sulfonate, methyl coconut oil Sodium taurate 3.0%, sodium laureth sulfate 12.0%, cocamidopropyl betaine 5.0%, coconut oil fatty acid diethanolamide 2.5% were dispersed in deionized water and ethylenediaminetetraacetic acid two by one Sodium 0.1%, heated to 80°C and stirred quickly; then added 0.4% guar gum, 1.0% PEG-7 glyceryl cocoate, 0.1% PEG-75 shea butter and 1.5% emulsified silicone oil to dissolve, and stir evenly; after cooling down to 45°C, add 0.4% hydantoin, 3.0% pearlescent syrup, 1.0% sodium chloride, 1.5% citric acid and 0.4% essence for constant weight, adjust the pH value, and stir until uniform .

Embodiment 3

[0039] A special shampoo for coal mines, prepared according to the following method from the following raw materials in weight percent (%): under water bath conditions, 5.0% decyl glucoside, 12.0% sodium α-alkenyl sulfonate, methyl coconut oil Sodium taurate 4.5%, sodium laureth sulfate 8.5%, cocamidopropyl betaine 6.0%, coconut oil fatty acid diethanolamide 4.5% were dispersed in deionized water and ethylenediaminetetraacetic acid two by one Sodium 0.1%, heated to 80°C and stirred quickly; then added 0.15% guar gum, 3.0% PEG-7 glyceryl cocoate, 0.2% PEG-75 shea butter and 3.0% emulsified silicone oil to dissolve, and stir evenly; after cooling down to 45°C, add 0.2% hydantoin, 5.0% pearlescent syrup, 1.5% sodium chloride, 2.0% citric acid and 0.3% essence for constant weight, adjust the pH value, and stir until uniform .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com