Hood module and method for producing hood module

A cover and bearing frame technology, which is applied to the sealing device, valve device, cylinder and other directions of the engine, can solve the problem of not having the ability to install the camshaft module.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

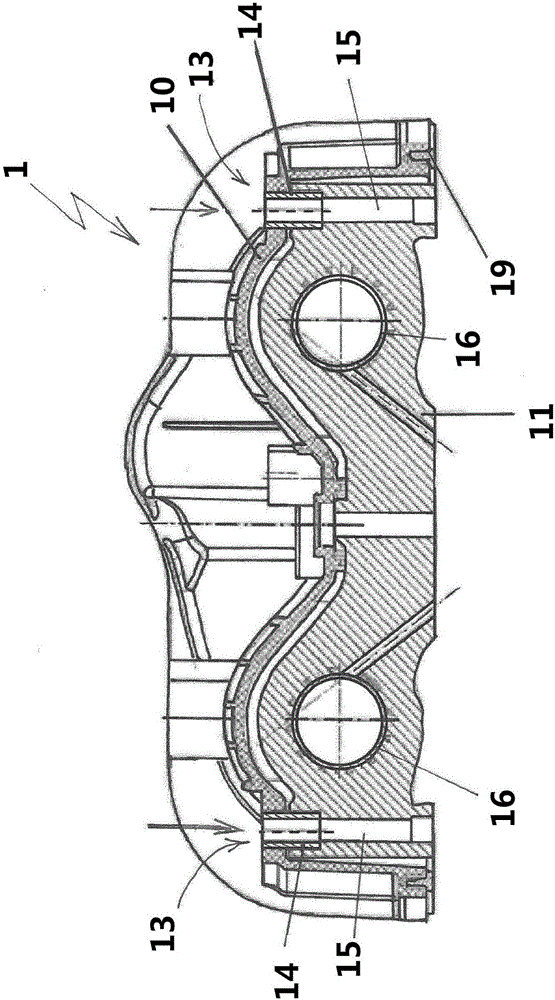

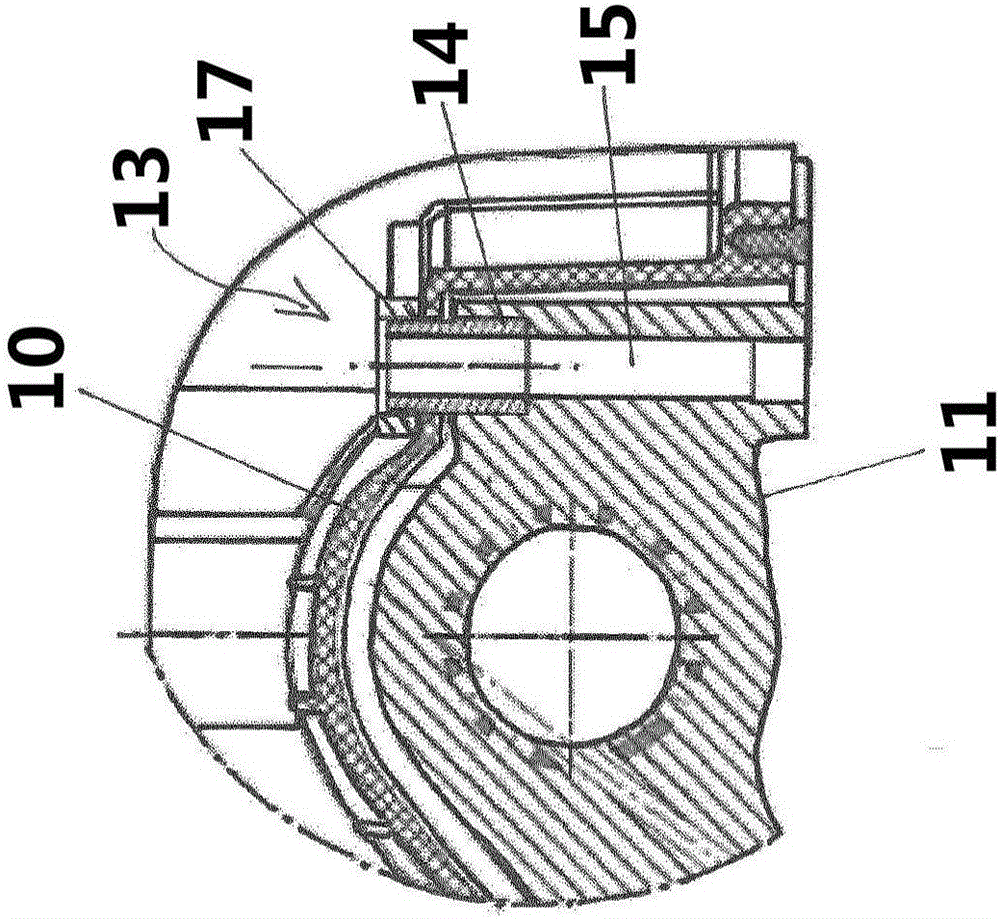

[0034] figure 1 The cover module 1 is shown in a perspective view from the bottom side and has a cover body 10 which has a cap-like or cover-like shape and forms the basic structure of the cover module 1 . The cover 10 is produced from plastic material by an injection molding process. For example, the shell can be produced from fiber-reinforced polyamide.

[0035] In the inner region of the housing 10 there are three visible bearing brackets 11 running parallel to one another for the rotatable holding of the two camshafts 12 . The side walls of the housing 10 also comprise further bearing brackets which are not present or are only partially present, so that the camshaft 12 is held on the housing module 1 by a total of five bearing brackets. The camshaft 12 can be inserted through an insertion opening 18 on one side of the housing 10 which can at the same time be the first bearing point for the camshaft 12, here the camshaft 12 is shown in simplified form without lifting elem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com