Silver-coated copper nanowire and preparation method therefor

A copper nanowire and silver-coated technology, which is applied in nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of increased production costs, low productivity of copper nanowires, and difficulty in large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

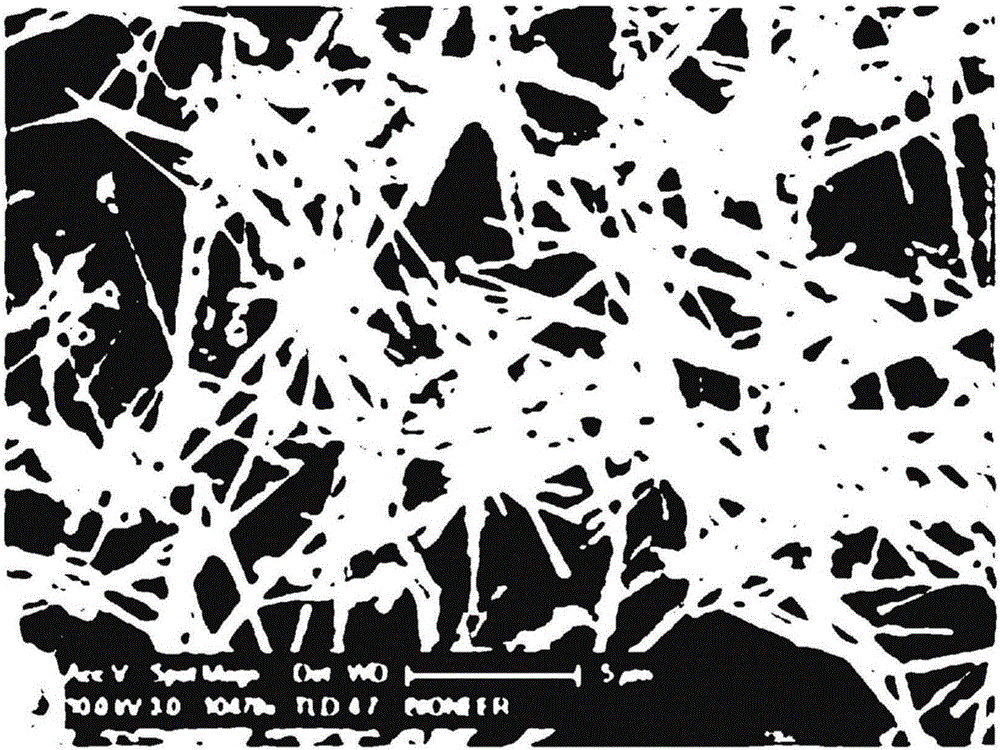

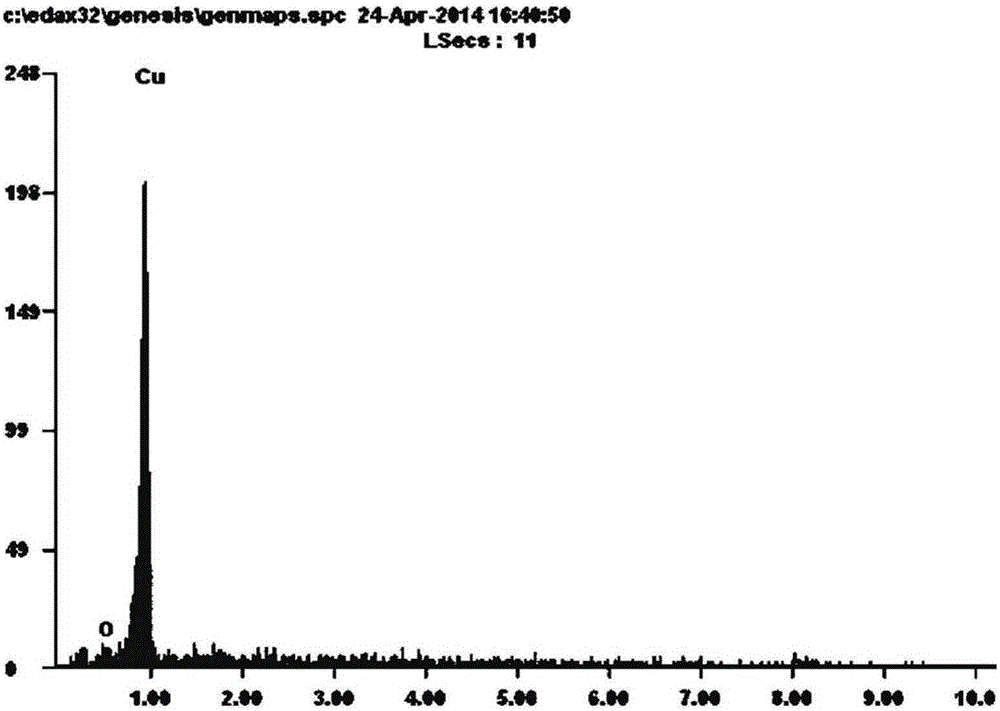

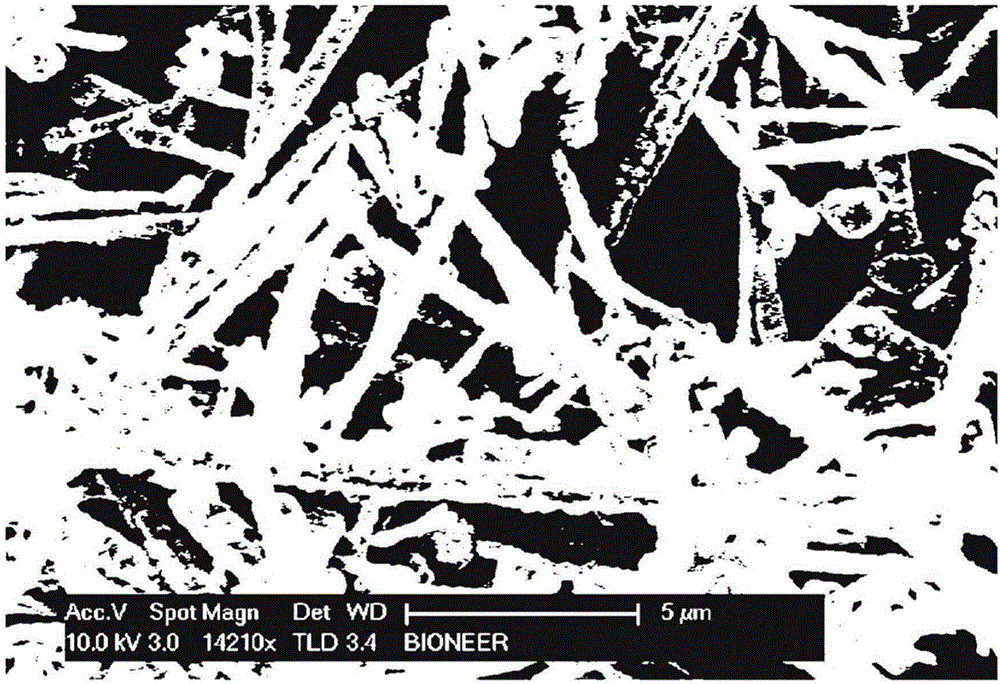

[0071] The silver-coated copper nanowires prepared by the preparation method of the present invention preferably have a length of 5-10 μm, a diameter of 200-300 nm, and a silver content of 5-90 parts by weight based on 100 parts by weight of the total nanowires, but the length, The diameter and silver content are not limited thereto.

[0072] Compared with conventional copper nanowires such as copper nanowires not coated with silver, the silver-coated copper nanowires of the present invention have better oxidation stability and thermal stability.

[0073] In the present invention, the silver content of the silver-coated copper nanowires may be 2-60 parts by weight based on 100 parts by weight of the total nanowires. When the silver content is less than 2 parts by weight based on the total weight, the copper nanowires cannot be completely coated with silver. When the silver content is 60 parts by weight or more, there is silver not coated on the copper nanowires, so there is a...

Embodiment 1

[0082] Embodiment 1: use piperazine (C 4 h 10 N 2 ) to prepare copper nanowires

[0083] 2000ml of water (ultrapure water) was added to a 3000ml round bottom flask and 1200g (15M) of sodium hydroxide (NaOH, Samchun Pure Chemical) was added while stirring in a stirrer. The internal temperature of the reactor heated by the exothermic reaction was cooled so as not to exceed 50 °C, and then 3.8 g (0.0079 M) of copper(II) nitrate (Cu(NO 3 ) 2 ·3H 2 O, Samchun PureChemical) was dissolved in 100ml of water (ultrapure water) and added to the reactor. Then 9.7g (0.268M) piperazine (C 4 h 10 N 2 , Sigma Aldrich) was dissolved in 100 ml of water (ultrapure water) and added to the reactor, then stirred at an average stirring rate of 300 rpm for 10 minutes. The temperature of the reactor was raised to 70°C. Then 4ml hydrazine (N 2 h 4 , Samchun Pure Chemical) was mixed with 240ml (0.04M) of water (ultrapure water), and then fed into the reactor at a rate of 4ml / min for 1 hour u...

Embodiment 2

[0084] Example 2: Silver Coating of Copper Nanowires Using Ethylenediamine

[0085] 200 ml of water (ultrapure water) and 0.5 g of copper nanowires prepared using piperazine were added to a 500 ml Erlenmeyer flask and treated at 53 kHz for 10 minutes using an ultrasonic cleaner (Youngjin Corporation Batch Sonicator, SK7210HP) to disperse the copper nanowires . In another beaker, add 0.3 g of silver nitrate (AgNO 3 , JUNETECH) and dissolved in 200ml (0.012M) water (ultrapure water) and added 0.7ml (0.036M) ammonia water (NH 4 OH, Samchun Pure Chemical) to prepare a clear liquid to which 1 ml (0.083M) ethylenediamine (Sigma Aldrich) was added and stirred well for 1 minute. A solution containing silver nitrate, ammonia water, and ethylenediamine was added thereto and stirred at room temperature for 1 hour while stirring the copper nanowire solution at a stirring rate of 300 rpm. When the reaction was completed, the reaction product was washed with 2 L of water (ultrapure water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com