Intelligent submersible motor with built-in controller

A submersible motor and controller technology, applied in the direction of connection with control/drive circuit, electrical components, electromechanical devices, etc., can solve problems such as increased heat generation, affecting the service life of the controller, and mechanical oil seals cannot be effectively lubricated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following descriptions are only preferred embodiments of the present invention, and do not limit the protection scope of the present invention. The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

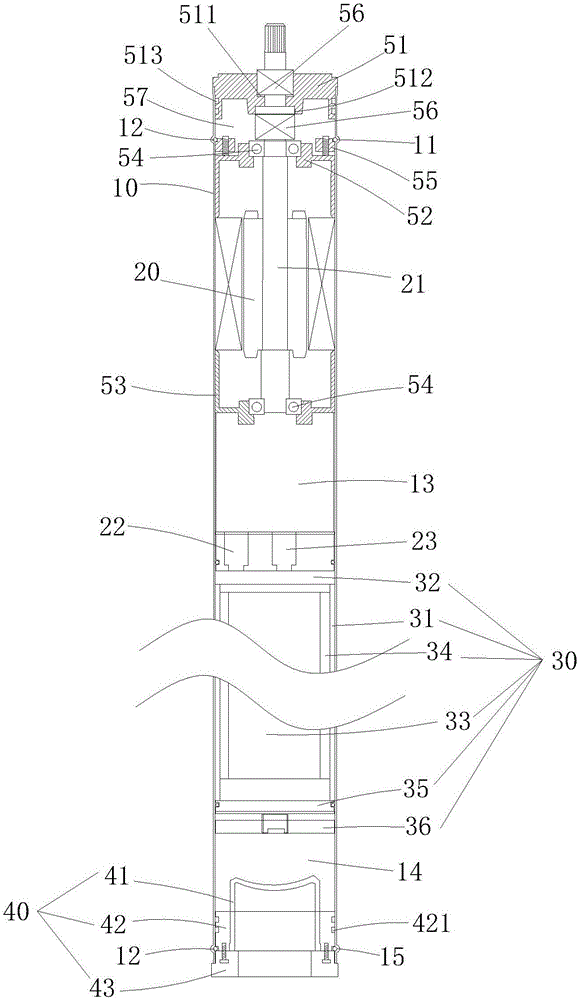

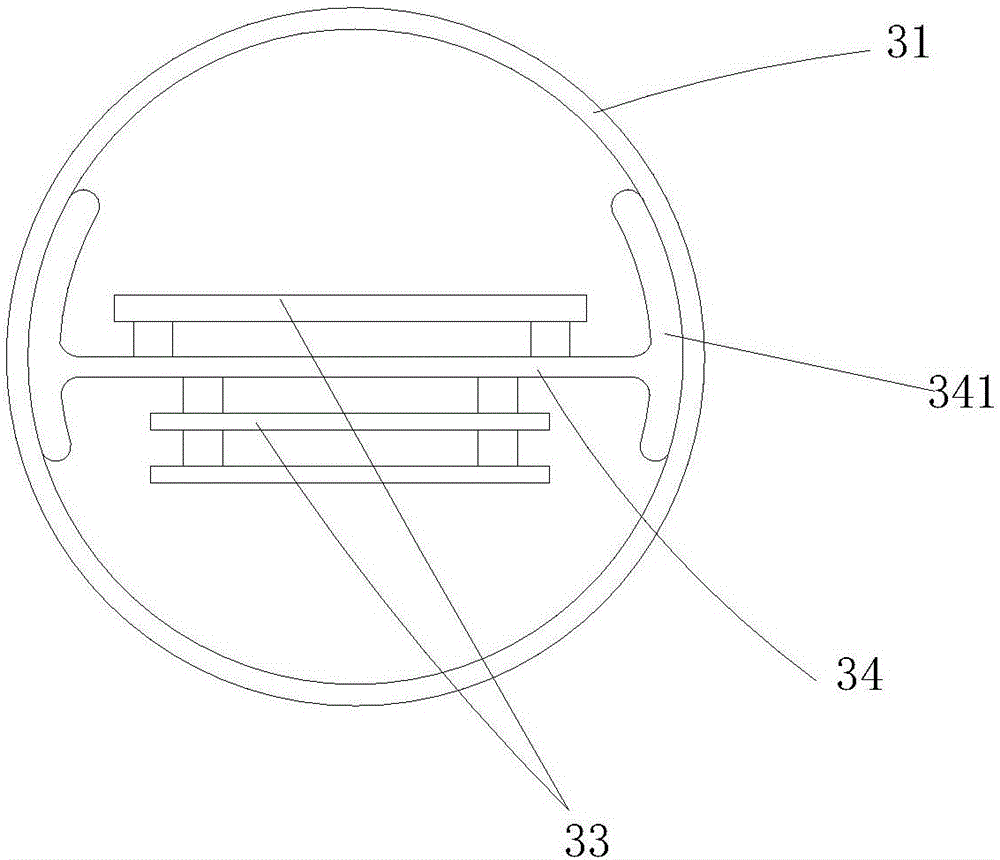

[0016] Examples, see figure 1 and figure 2 As shown: an intelligent submersible motor with a built-in controller, including a body 10, the body 10 is hollow inside and has a through structure at both ends. A brushless DC stator / rotor assembly 20, a variable frequency sealing device 30, a base sealing assembly 40 and an end cover sealing assembly are arranged inside the machine body 10. The end cover sealing assembly includes a motor end cover 51, an upper bearing seat 52, a lower bearing seat 53, The bearing 54, the top clamping plate 55 and the mechanical oil seal 56, the end of the motor end cover 51 is fixedly connected with the end of the body 10, and an outer mechanical oil seal groove 511 and an inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com