H-MoS2/NG nanocomposite material and preparation method and application thereof

A nanocomposite material and nanoparticle technology, which is applied in the field of H-MoS2/NG nanocomposite material and its preparation, can solve problems such as production limitations, and achieve the effects of easy scale, uniform growth, and low overpotential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

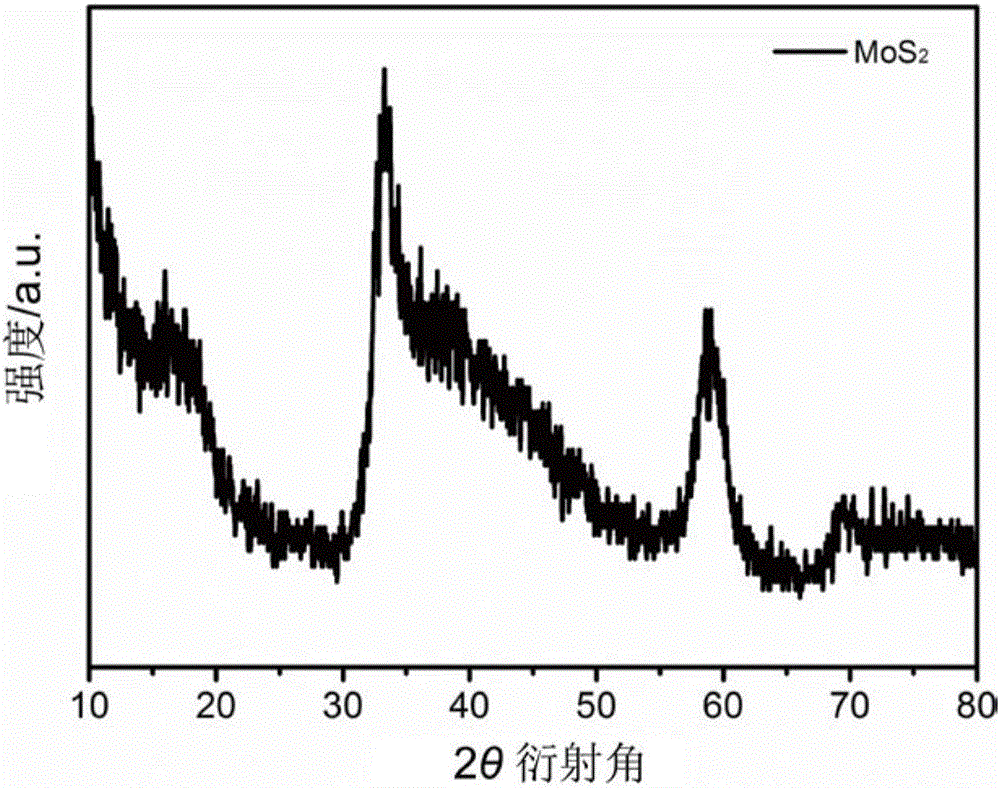

[0043] MoS 2 The composition of the hydrothermal reaction solution of hollow nanospheres is 0.87g molybdenum trioxide, 0.52g sodium fluoride, 1.93g potassium thiocyanate and 30mL deionized water.

[0044] The composition of the NG hydrothermal reaction solution was 30 mL of graphene oxide, 15 mL of ammonia water and 100 mg of NaOH.

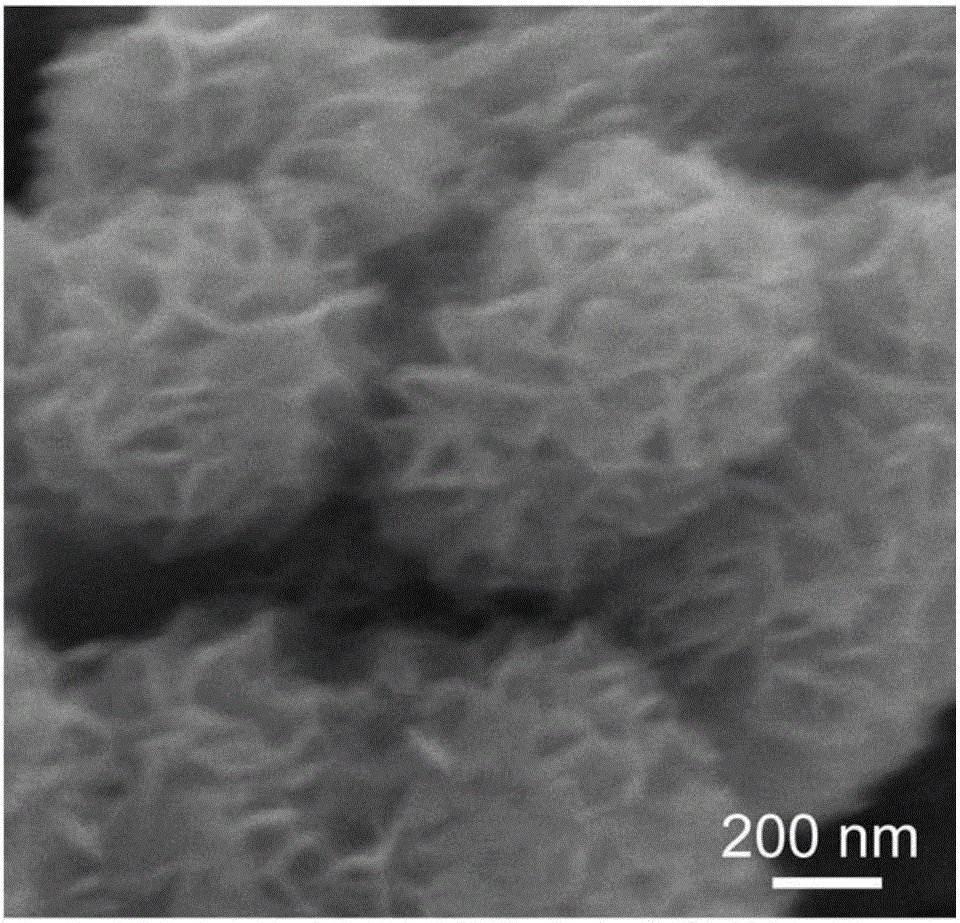

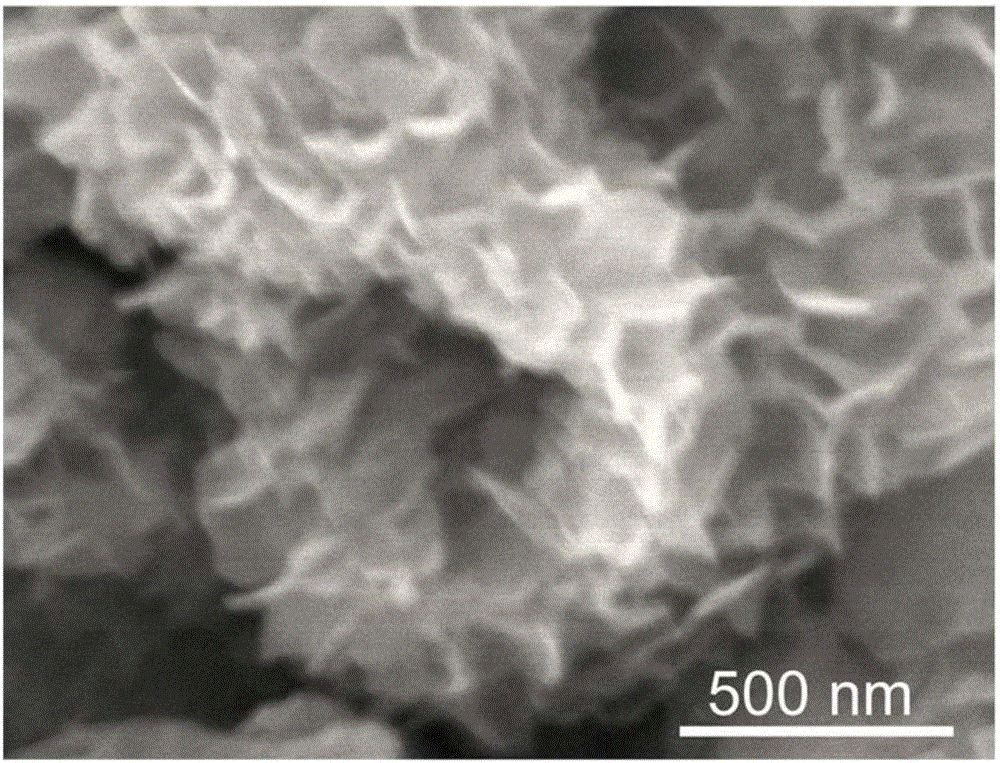

[0045] MoS 2 The synthesis of nano hollow spheres is realized by hydrothermal method. MoS 2 The hollow nanosphere growth solution is placed in a high-pressure reactor (the reaction solution is generally 80% of the volume of the reactor), and the hydrothermal reaction is maintained at 220° C. for 24 hours. After the reaction was completed, it was cooled to room temperature, and the obtained sample was repeatedly washed three times with deionized water, and dried at 80°C.

[0046] The MoS obtained above 2 Nanohollow spheres (0.5 g) were dispersed in toluene solution by ultrasound. After 1h, 0.5mL APS was added to the above solution, and APS-mo...

Embodiment 2

[0049] MoS 2 The composition of the hydrothermal reaction solution of hollow nanometer spheres is 0.85g molybdenum trioxide, 0.50g sodium fluoride, 1.8g potassium thiocyanate and 20mL deionized water.

[0050] The composition of NG hydrothermal reaction solution is graphene oxide 10mL, ammonia water 15mL and NaOH 80mg.

[0051] MoS 2 The synthesis of nano hollow spheres is realized by hydrothermal method. MoS 2 The hollow nanosphere growth solution is placed in a high-pressure reactor (the reaction solution is generally 80% of the volume of the reactor), and the hydrothermal reaction is maintained at 200° C. for 26 hours. After the reaction was completed, it was cooled to room temperature, and the obtained sample was repeatedly washed three times with deionized water, and dried at 80°C.

[0052] The MoS obtained above 2 Nanohollow spheres (0.2 g) were dispersed in toluene solution by ultrasound. After 1h, 0.2mL APS was added to the above solution and stirred for 24h to o...

Embodiment 3

[0054] MoS 2 The composition of the hydrothermal reaction solution of hollow nanospheres is 0.88g molybdenum trioxide, 0.51g sodium fluoride, 2g potassium thiocyanate and 40mL deionized water.

[0055] The composition of NG hydrothermal reaction solution is graphene oxide 40mL, ammonia water 30mL and NaOH 90mg.

[0056] MoS 2 The synthesis of nano hollow spheres is realized by hydrothermal method. MoS 2 The hollow nanosphere growth solution is placed in a high-pressure reactor (the reaction solution is generally 80% of the volume of the reactor), and the hydrothermal reaction is maintained at 230° C. for 18 hours. After the reaction was completed, it was cooled to room temperature, and the obtained sample was repeatedly washed three times with deionized water, and dried at 80°C.

[0057] The MoS obtained above 2 Nanohollow spheres (0.8 g) were dispersed in toluene solution by ultrasound. After 1h, 0.8mL APS was added to the above solution and stirred for 24h to obtain AP...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com