Explosion-proof safety top cover for battery

A top cover and safety technology, which is applied in the direction of battery cover/end cover, battery pack parts, battery box/coating, etc., can solve the problem of reduced strength of pressure relief valve, high battery scrap rate, affecting battery capacity, cycle and shelf performance To achieve the effect of preventing explosion safety accidents, improving explosion-proof safety performance, and good industrial application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing:

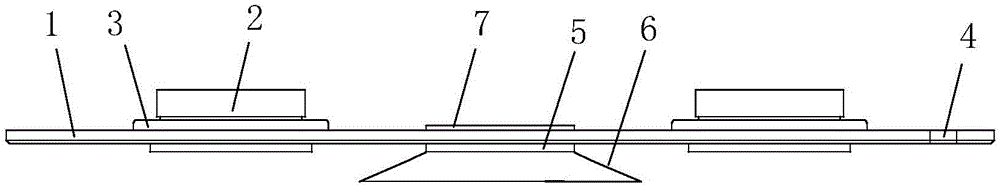

[0019] Such as figure 1 The explosion-proof safety top cover of the battery shown includes a top cover substrate 1, on which a pole 2, a metal spacer 3 and a liquid injection hole 4 are arranged, and the metal spacer 3 and the pole 2 are riveted or welded. The electrical connection is realized in a manner, and one or two of the poles 2 are insulated from the metal spacer 3 through insulating gaskets. The top cover substrate 1 is also provided with an explosion-proof assembly, and the explosion-proof assembly includes a gas collection hood base 5 fixed with the top cover substrate 1, a gas collection hood 6 connected to the gas collection hood base 5, and a gas collection hood 6 placed in the center of the gas collection hood base 5. Pressure relief valve 7 at.

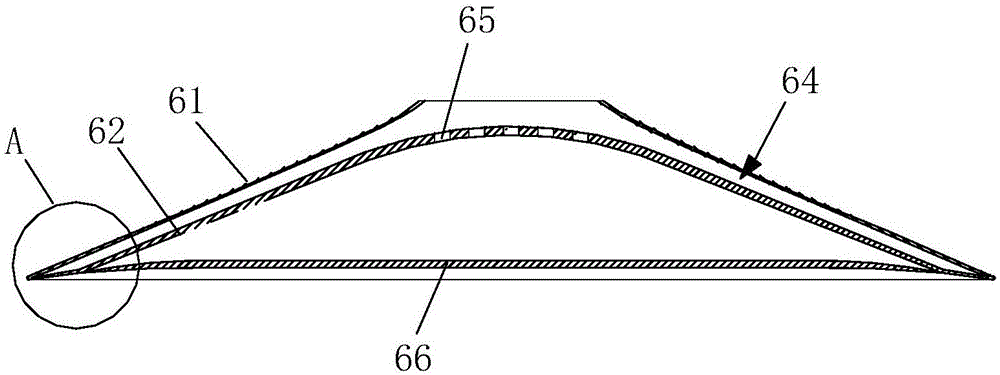

[0020] Further, such as figure 2 , image 3 , Figure 4 As shown, the gas collecting hood 6 has a gradually...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com