Flexible pressure sensor and preparation method therefor

A pressure sensor, flexible technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, measurement of elastic deformation force by measuring gauges, etc., can solve the needs of Annealing etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

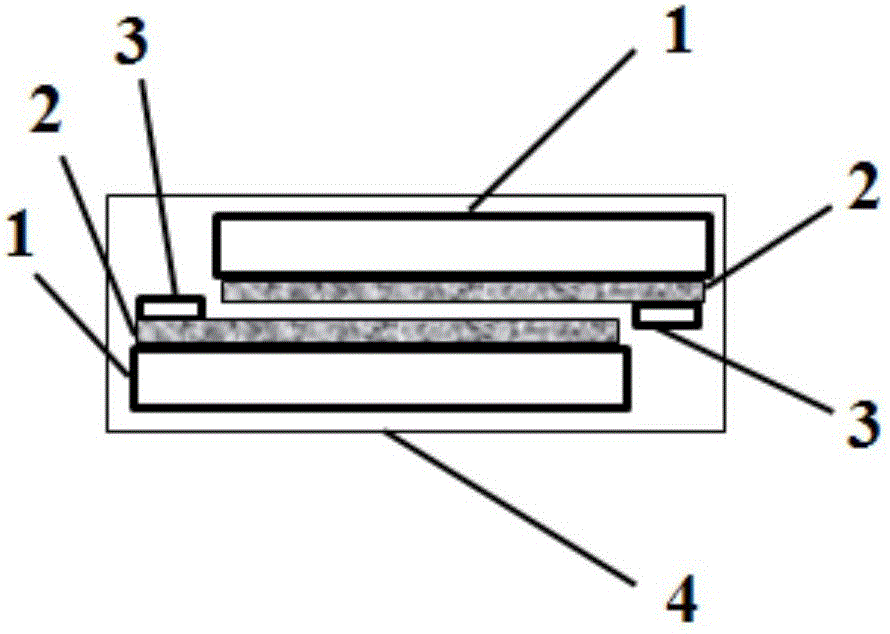

[0071] This embodiment provides a flexible pressure sensor, which includes an upper flexible substrate and a lower flexible substrate arranged in parallel, an upper sensitive layer conformally attached to the lower surface of the upper flexible substrate and an upper sensitive layer conformally attached to the upper surface of the lower flexible substrate. The lower sensitive layer; the upper sensitive layer is provided with an upper electrode, the lower sensitive layer is provided with a lower electrode, and the upper electrode and the lower electrode are respectively arranged on the edge of the upper sensitive layer and the lower electrode On the side of the sensitive layer, the upper electrode and the lower electrode do not cross each other; a contactable area is formed between the upper sensitive layer and the lower sensitive layer. An encapsulation layer 4 is contained outside the upper flexible substrate and the lower flexible substrate, such as figure 1 shown. Wherein,...

Embodiment 2

[0084] This embodiment provides a flexible pressure sensor. The structure of the flexible pressure sensor is the same as that in Embodiment 1.

[0085] This embodiment also provides a preparation method for the above-mentioned flexible pressure sensor, and the specific steps are as follows:

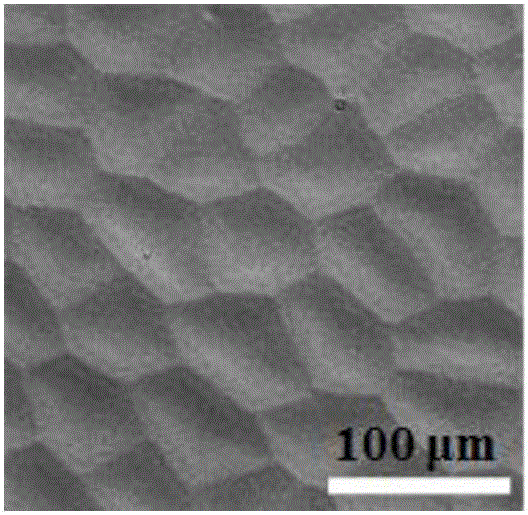

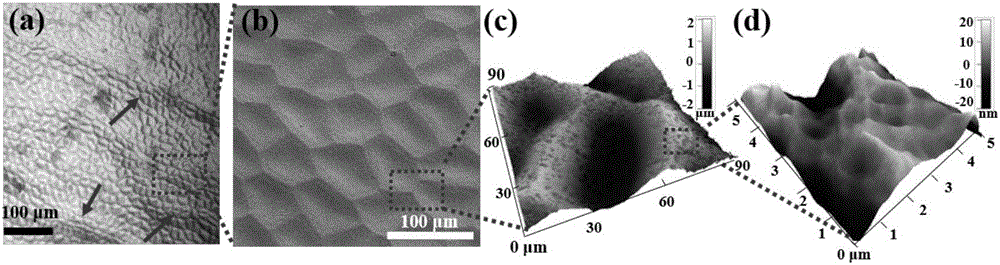

[0086] Step 1. Mix the precursor of polydimethylsiloxane and the curing agent evenly according to the ratio of 10:1, and drop-coat it on the surface of the cleaned and dried fresh pothos leaves;

[0087] Step 2. After the polydimethylsiloxane is basically flat on the surface of the blade, place it in an oven at 80°C to cure for 3 hours. After the curing is complete, remove the polydimethylsiloxane film to obtain a substrate with a microstructure;

[0088] Step 3. The carbon nanotube film is directly extracted from the vertical carbon nanotube array, with a width of 2 cm, placed on the surface of the copper foil, and ethanol is added dropwise, and the carbon nanotube film is firmly bonded...

Embodiment 3

[0097] This embodiment provides a flexible pressure sensor. This embodiment provides a flexible pressure sensor. The structure of the flexible pressure sensor is the same as that in Embodiment 1.

[0098] This embodiment also provides a preparation method for the above-mentioned flexible pressure sensor, and the specific steps are as follows:

[0099] Step 1. Mix the precursor of polydimethylsiloxane and the curing agent evenly according to the ratio of 10:1, and drop-coat it on the surface of the cleaned and dried fresh pothos leaves;

[0100] Step 2. After the polydimethylsiloxane is basically flat on the surface of the blade, place it in an oven at 70°C to cure for 3 hours. After the curing is completed, remove the polydimethylsiloxane film to obtain a substrate with a microstructure. The thickness of the flexible substrate is 250 μm;

[0101] Step 3, the carbon nanotube film is directly extracted from the vertical carbon nanotube array, placed on the surface of the copp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com