Test method applying compressing load and stretching load in vertical direction and horizontal direction simultaneously

A technology in a horizontal direction, a test method, applied in the direction of using a stable tension/pressure to test the strength of materials, etc., can solve the problem of poor shape memory effect, inability to give shape memory polymer-based materials at the same time shape memory effect, material fixation rate and recovery low rate issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

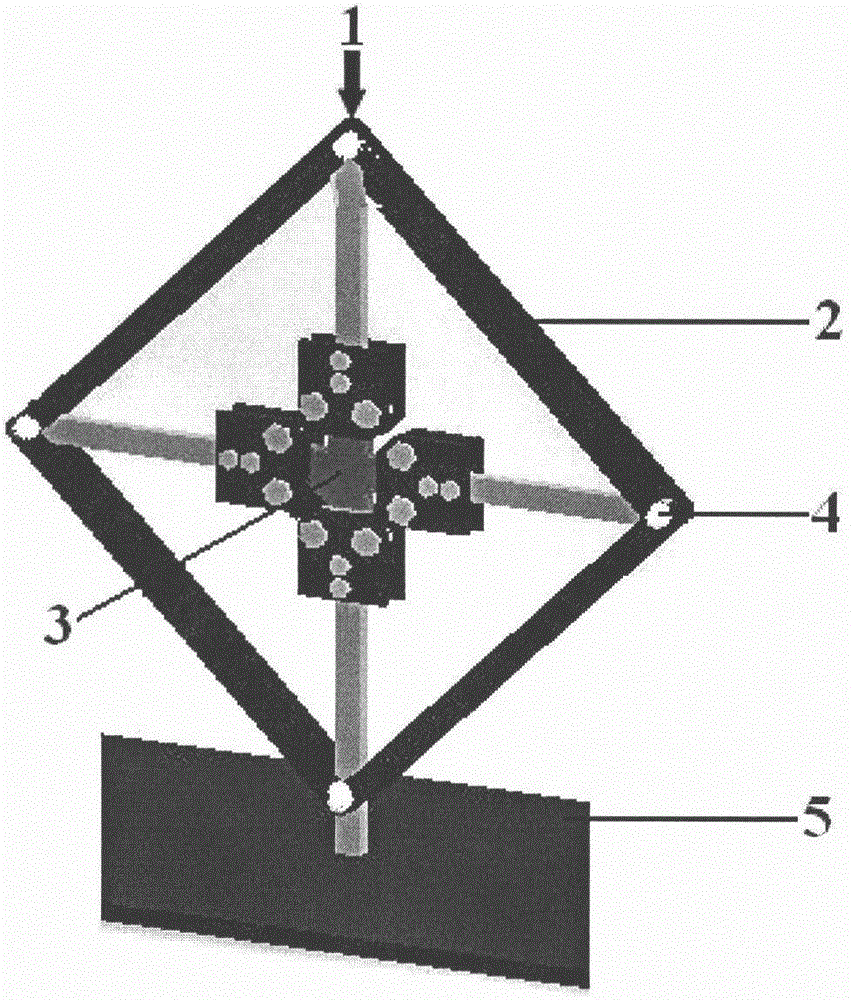

[0016] The invention provides a test method for applying compressive and tensile loads simultaneously in the vertical and horizontal directions, and the specific implementation steps are as follows:

[0017] (1) Select a polymer raw material with low price and good shape memory effect, prepare a shape memory polymer based material according to the compound formula, process it into a cross-shaped specimen, and mark the center of the cross-shaped specimen as a quartered square , installed and fixed in a biaxial training fixture;

[0018] (2) Using differential scanning calorimetry to determine the glass transition temperature of shape memory polymer-based materials, place the specimen fixed in the fixture in the environmental chamber, and apply a certain compressive load on the top of the fixture, and pass through the fixture bar The hinged structure enables the specimen to be subjected to compressive and tensile stresses in the vertical and horizontal directions respectively; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com