Novel mobile type hot-water boiler efficiency testing platform and method

A hot water boiler and efficiency detection technology, which is applied in the direction of measuring devices, machine/structural component testing, instruments, etc., can solve the problems of more testing personnel, low testing efficiency, and dangerous testing, so as to improve testing efficiency, The effect of increasing heat exchange area and saving consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

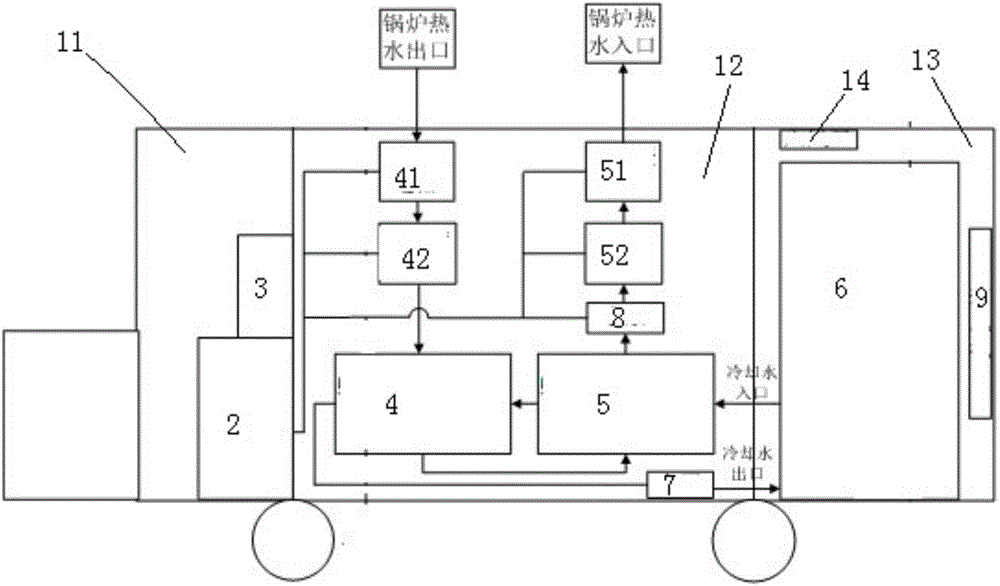

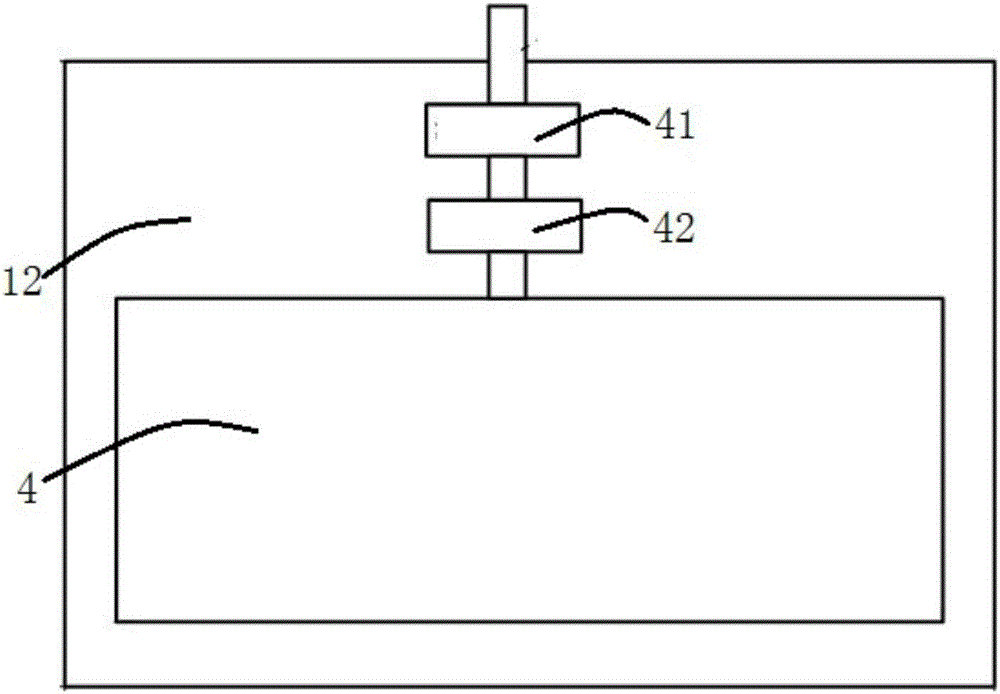

[0022] Such as Figure 1 to Figure 3 所示,一种新型移动式热水锅炉效率检测平台,包括可移动的车体,所述车体上设有集控室11、换热室12和冷却室13,所述集控室11内安装有PLC控制系统2和显示器3,所述冷却室13内安装有冷却水箱6,所述换热室12内安装有第一换热器4和第二换热器5,换热器通过固定支架对称安装在换热室12的两侧,所述冷却水箱6、第一换热器4和第二换热器5通过冷却水管道依次循环连接,所述冷却水管道上安装有冷却水泵7,所述换热室12内还安装有锅炉热水管道,所述锅炉热水管道依次连接所述第一换热器4和第二换热器5,所述第一换热器4的锅炉热水进口端还安装有第一流量监测器41和第一温度传感器42,所述第二换热器5的锅炉热水出口端安装有第二流量监测器51和第二温度传感器52,所述锅炉热水管道上安装有热水泵8;所述PLC控制系统2电气连接所述显示器3、第一流量监测器41、第一温度传感器42、第二流量监测器51、第二温度传感器52、冷却水泵7和热水泵8,根据所述第一流量监测器41、第一温度传感器42、第二流量监测器51和第二温度传感器52的反馈数据,实时计算锅炉效率并通过所述显示器3显示所计算结果,并同时控制所述冷却水泵7和热水泵8工作。 .

[0023] 所述第一换热器4和第二换热器5均采用螺旋板式换热器。

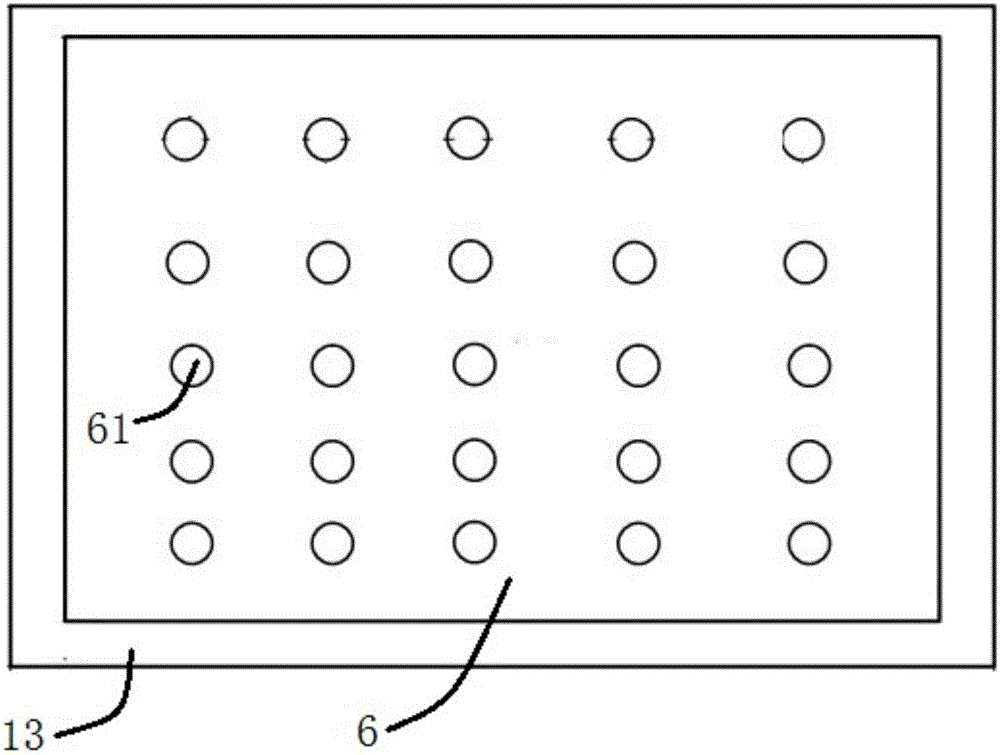

[0024] 所述车体上开设有连通所述冷却室13的通风口14,通风口14的直径为0.5m-1m,所述冷却室13内安装有冷却风机9,冷却风机安装在于车体后门的中间位置,根据锅炉检测需要,冷却风机的直径为0.5m-1m,冷却风机与冷却箱的距离为5-50cm,所述冷却水箱6中设有若干根通风管61,增加换热面积,确保冷却水被充分冷却。冷却水泵7选用普通的增压水泵,冷却风机9选用工业离心排风机,通风口14设置于冷却室13上方。

[0025] PLC控制系统2主要包括:温度、流量检测信号实时传输和给水泵、冷却水泵、抽风机的实时控制两部分。通过上位机软件,可以实时查看锅炉出水、入水温度和流量,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com