Flat pushing type feeding device for incineration fire grate

A feeding device and incinerator technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve the problems of reducing the economic benefits of waste incineration power plants, increasing the heat loss of waste combustion, and not being able to completely and fully burn, etc., to achieve effective Good for drying, reducing operating costs, and evenly burning waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

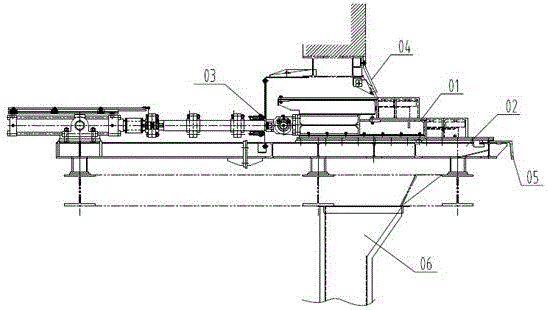

[0020] Such as figure 1 As shown, the horizontal push type incinerator grate feeding device is mainly assembled from four parts: the body component, the platform component, the driving device component, and the baffle plate component.

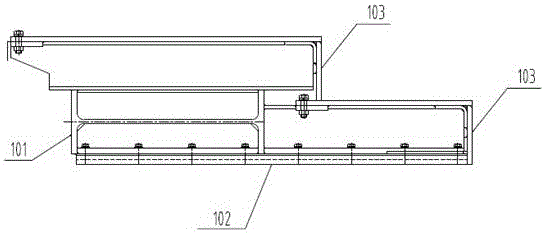

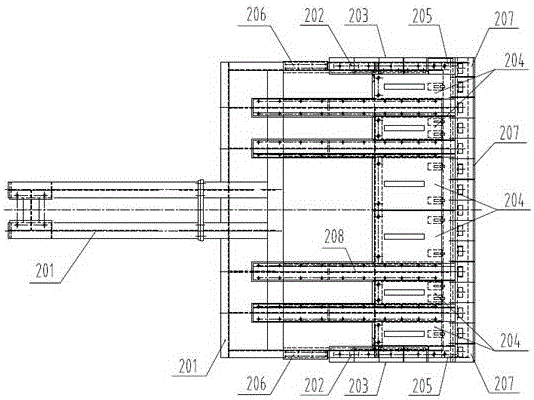

[0021] In the process of assembling the bench, first find the datum of the bench platform 201, and keep the horizontal state of 0°; figure 2 As shown, the side guide plate platform 202 is respectively installed on the left and right sides of the bench platform 201, and the side guide plate 203 is installed on the upper part of the side guide plate platform 202 to ensure the size of the furnace; the stainless steel bottom plate 205 is installed on the bench platform 201 at the tail ends of the left and right sides; the stainless steel guard plate (with a 30° inclination angle) 206 is installed in the middle of the left and right sides of the platform platform 201, so that it is easier for the garbage leachate to flow into the lower collection b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com