No-open-flame fuel gas uniform-temperature heating device

A heating device, no open flame technology, applied in the field of heat treatment, can solve the problems of heating temperature fluctuation, unevenness, slow workpiece running, etc., to achieve the effect of constant temperature, uniformity promotion, and temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

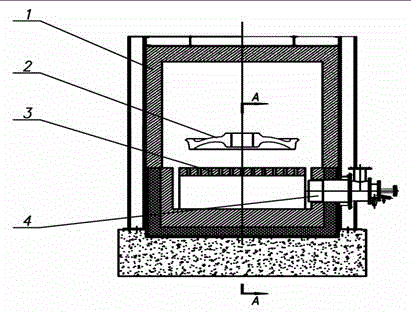

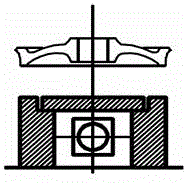

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

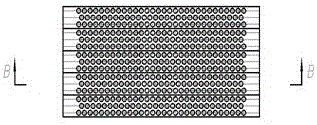

[0030] Such as figure 1 As shown, the heating furnace body 1 adopts light fiber and light bricks as the insulation layer, the workpiece to be heated 2 is suspended in the heating furnace body 1, and the soaking fire insulation box 3 is made of heavy refractory bricks. The side foundation wall is built by standard refractory bricks, and the upper refractory bricks are prefabricated and sintered with low cement castables. There are smoke distribution holes on the refractory bricks, and the high-temperature smoke rises evenly from the smoke distribution holes to heat the workpiece; the air And the gas is sprayed out of the burner after being burned in the combustion chamber of the gas burner 4. The flame is very short at about 200mm, but there is still an open flame sprayed out of the burner to form a bright radiation source, and the high-speed and high-temperature flue g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com