Overheat early warning method for supercritical boiler heating surface pipe wall using discretization conversion

A technology for supercritical boilers and heating surface tubes, which is applied in the direction of steam boilers, steam boiler accessories, steam boiler components, etc., and can solve the problems of simple prediction of temperature, high production process requirements, and inability to prevent overheating, etc. Problems, achieve the effect of reducing the number of overheating, reducing costs and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

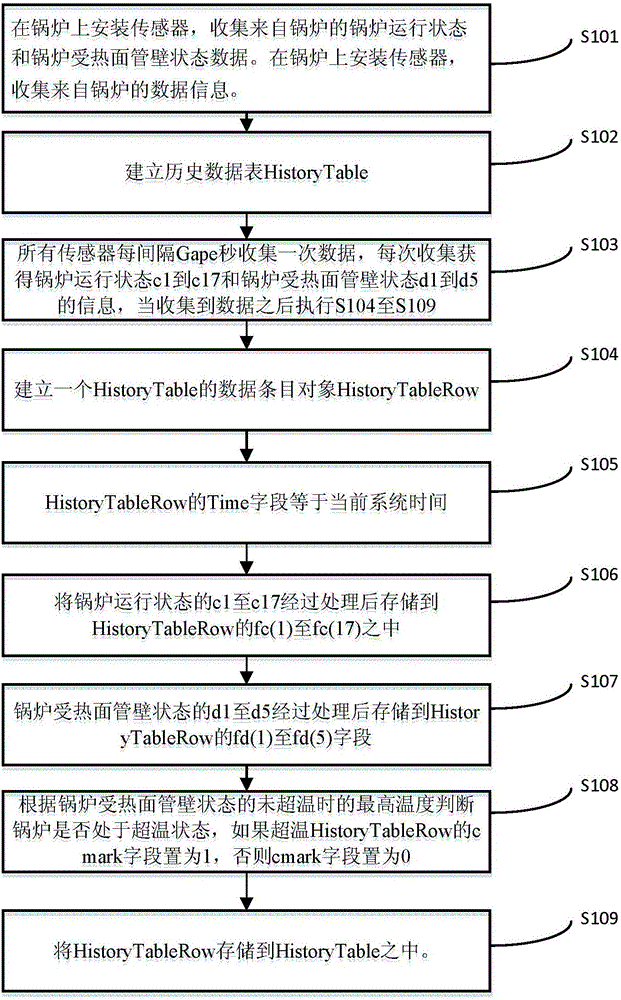

[0036] Specific implementation mode one: combine figure 1 A discretized conversion supercritical boiler heating surface tube wall overtemperature early warning method in this embodiment is specifically prepared according to the following steps:

[0037] Step 1. Install sensors on the boiler, collect M rows of boiler operating status data and M rows of boiler heating surface tube wall status data at intervals of Gape seconds and store them in the historical data table HistoryTable; the process of collecting and storing data is as follows figure 2 shown;

[0038] Among them, Gape is the number of seconds between data collection intervals, and the default is 10 seconds; the boiler operating status includes 17 kinds of status information:

[0039] Generator power c1, high pressure feed water pressure c2, high pressure feed water temperature c3, desuperheater inlet steam temperature c4, desuperheater outlet steam temperature c5, furnace side main steam pressure c6, furnace main st...

specific Embodiment approach 2

[0061] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 1, a sensor is installed on the boiler, and the boiler operation status data and boiler heating surface tube wall status data of the boiler are collected at intervals of Gape seconds and stored in the history The specific process in the data table HistoryTable is:

[0062] Step 11. Install sensors on the boiler to collect boiler operating status data from the boiler and boiler heating surface tube wall status data; install sensors on the boiler to collect data information from the boiler, which are divided into two categories:

[0063] Step 12. Establish a historical data table HistoryTable; the HistoryTable contains the following fields: the storage time Time of the data entry, the information fc1 to fc17 of c1 to c17 storing the operating state of the boiler, and the d1 to d5 of storing the tube wall of the heating surface of the boiler The information fd1 to fd5 an...

specific Embodiment approach 3

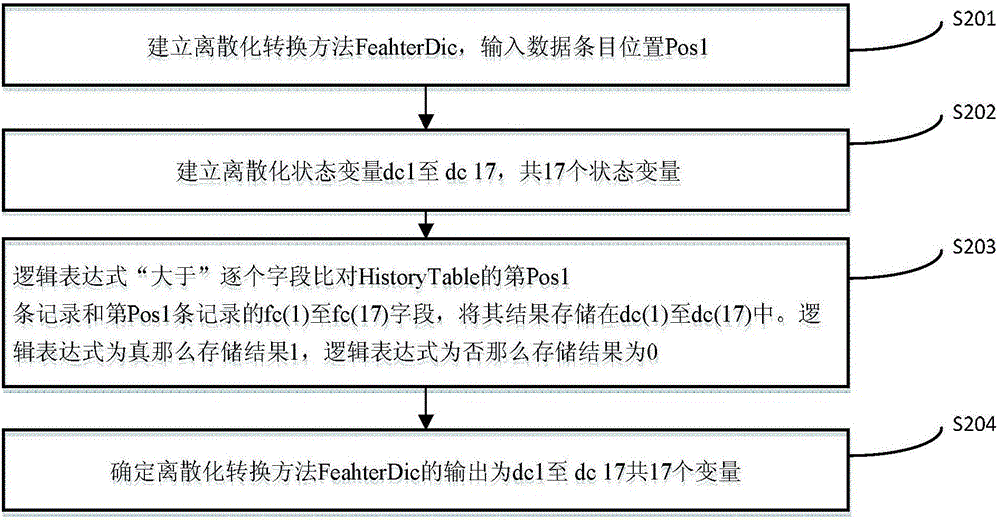

[0079] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: in the step 2, utilize the discretization conversion method FeahterDic to output dc1 to dc17 total 17 variables of the m row. The specific process is:

[0080] Step 21, establish the discrete conversion method FeahterDic, and input the data entry position Pos1 of HistoryTable;

[0081] Step 22, establishing discretized state variables dc1 to dc17, a total of 17 state variables;

[0082] Step two and three, determine the logical expression according to the 17 state variables c1 to c17, if the logical expression is true then store the result as 1, if the logical expression is false then store the result 0;

[0083] The logical expression "greater than" compares the fc1 to fc17 fields of the Pos1 record and the Pos1-1 record of the HistoryTable field by field, and stores the result in dc1 to dc17; if the logical expression is true, store the result 1, logical If the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com