Gas well automatic water draining plunger

An automatic drainage and plunger technology, applied in machine/engine, wellbore/well components, liquid fuel engine, etc., can solve problems such as process failure, increase workover operations, reduce plunger life, etc., to avoid excessive liquid leakage , The effect of improving the success rate of drainage and reducing management costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

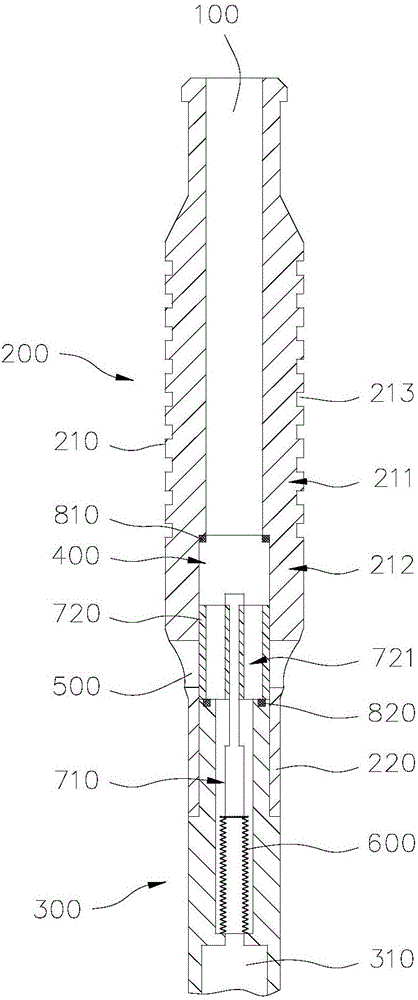

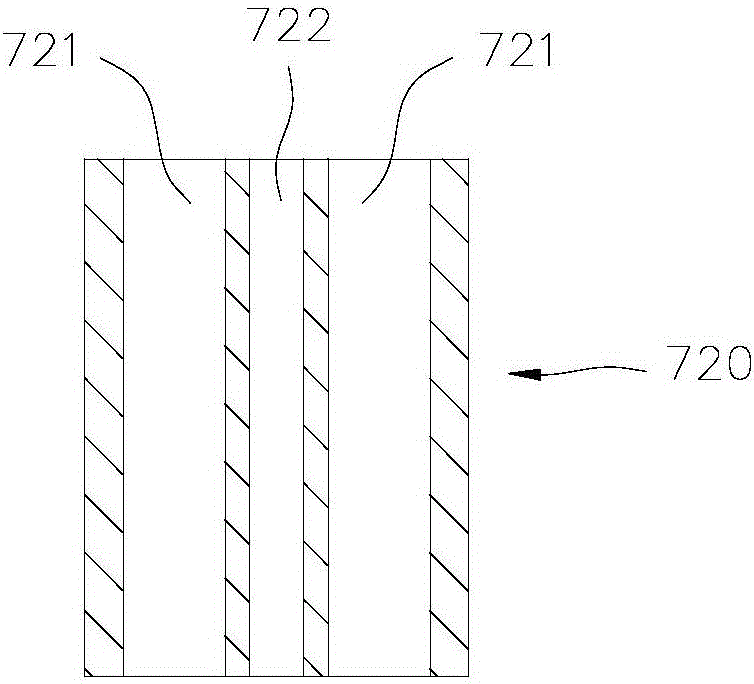

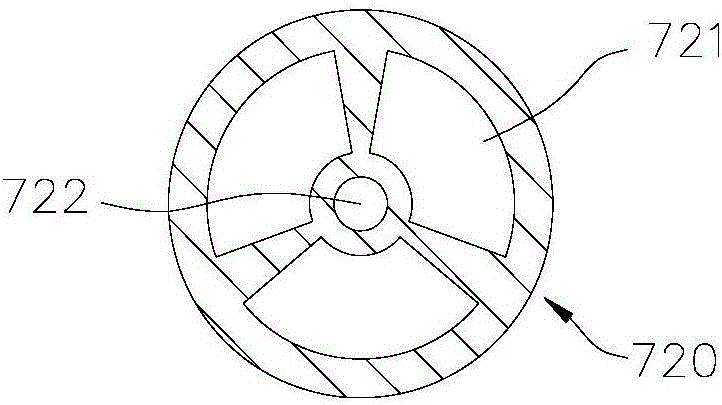

[0036] Such as figure 1 and Figure 5 As shown, the gas well automatic drainage plunger of the present invention includes a plunger cylinder body provided with a through hole 100 in the axial direction. The control mechanism of the plunger cylinder at least includes a first cylinder unit 210 and a second cylinder unit 220 with outer diameters from large to small, and the first cylinder unit 210 and the second cylinder unit 220 are provided with a limit The position groove 400, the second cylinder unit 220 is provided with a bypass channel 500 that can communicate with the through hole 100 along the radial direction of the limit groove 400, and the control mechanism is provided with the upper chamber and the lower chamber. The pressure difference between the chambers is transformed into an elastic sensitive element 600 for axial displacement, and the elastic sensitive element 600 is connected to and can slide reciprocally along the limit groove 400 under the action of the elas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com