Vertical environment-friendly novel copper foil production device

A kind of production equipment and vertical technology, applied in electrolysis process, electroforming, etc., can solve the problems of long production equipment cycle, high energy consumption, and difficult engineering, and achieve convenient and fast installation, guaranteed cleaning effect, and wide practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

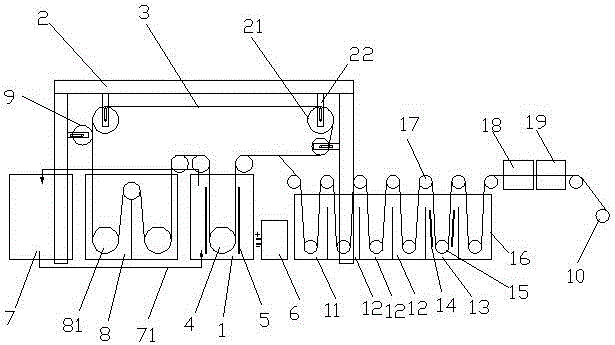

[0022] Such as figure 1 As shown, a new type of vertical environment-friendly copper foil production equipment includes a synchronous power supply 6, a copper foil working tank 1 and a bracket 2 arranged above the copper foil working tank 1, and the copper foil working tank 1 is provided with a The negative electrode of the synchronous power supply 6 is connected to the first cathode roller 4, and the first anode plate 5 connected to the positive electrode of the synchronous power supply 6 is provided on both sides of the first cathode roller 4, and the top of the support 2 is provided with There are two guide wheels 21, the guide wheels 21 and the first cathode roller 4 are connected by a strip-shaped copper foil generation carrier 3, and the copper foil generation carrier 3 enters the copper foil working tank 1 in a vertical manner , One side of the copper foil work...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com