Magnesium electrolyzer assembly line and method of merging single cell operation into assembly line

A magnesium electrolytic cell and assembly line technology, applied in the field of magnesium electrolysis, can solve the problems of complicated operation and interrupted operation of the assembly line, and achieve the effect of simple operation and reduced feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

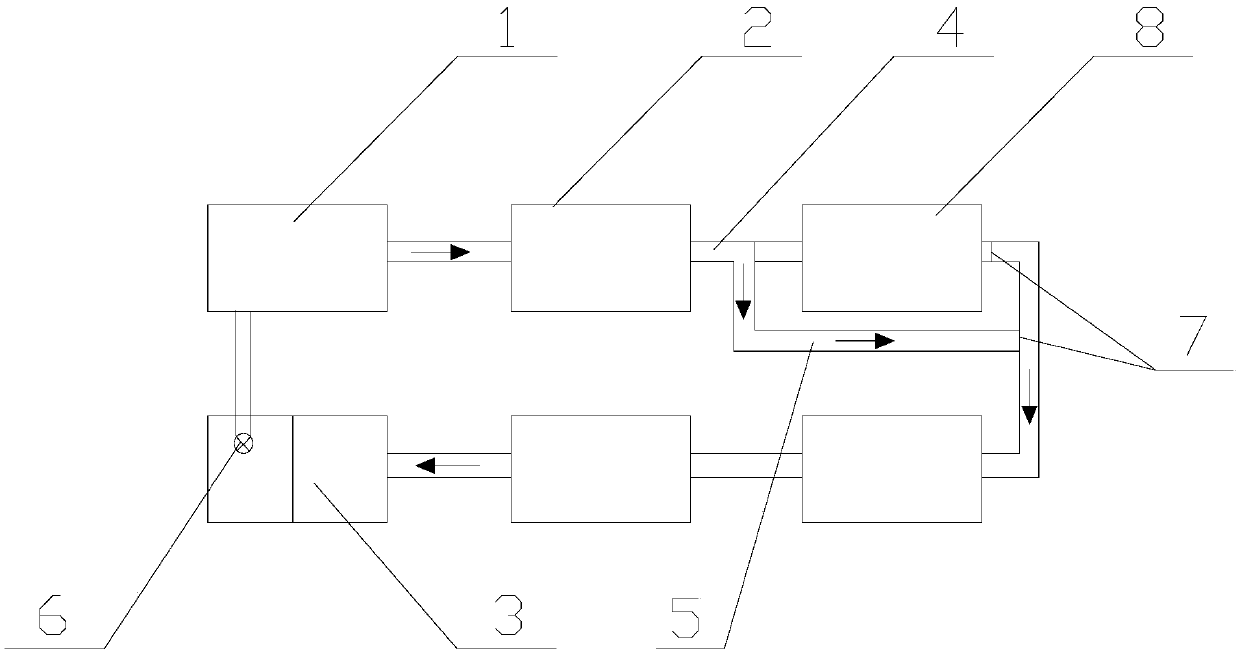

[0022] The present invention is further described below by accompanying drawing.

[0023] Such as figure 1 As shown, the magnesium electrolyzer assembly line of the present invention includes a head tank 1, an electrolyzer 2 and a separation tank 3 connected in sequence through a connecting channel 4, and the electrolyzer 2 includes a plurality and is connected in series, and each electrolyzer 2 A section of bypass channel 5 is arranged between the two ends, and the two ends of the bypass channel 5 are connected with the connecting channel 4. An air pump 6 is arranged in the separation tank 3, and the air pump 6 is used to displace the electrolyte in the separation tank 3. The melt is transported to the head tank 1 to form a circulation line. The head tank 1 is mainly used to add magnesium chloride and solid salt, the electrolytic tank 2 is used to generate magnesium and chlorine by electrolysis, the separation tank 3 is used to collect the magnesium produced by electrolysis,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com