Preparation method of insect-repelling bacteriostatic plant agent included in anti-corrosion reflective coating material

A reflective coating and corrosion-resistant technology, which is applied in the field of preparation of plant insect-repellent and antibacterial agents, can solve problems such as high price, toxicity, and adverse health effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

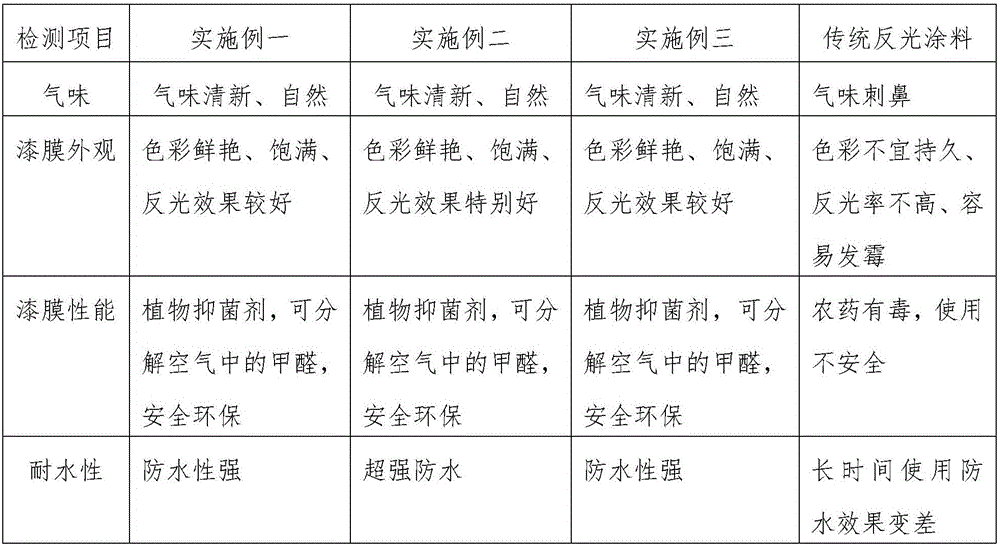

Examples

preparation example Construction

[0022] The preparation method of the plant insect-proof and bacteriostatic agent included in the corrosion-resistant reflective paint of the present invention comprises the following steps:

[0023] S1: Beat mint, garlic, ivy and begonia with a weight ratio of 1.5-2:1.8-2.3:1:2.5-3 into coarse powder, and pass through a 30-mesh sieve;

[0024] S2: Put mint, garlic, ivy and begonia coarse powder into the percolation cylinder, and use 60% hydrous ethanol for percolation extraction. If the weight of raw materials is 1kg, the amount of hydrous ethanol is 10 liters, and the flow rate is 8mL / min. collection of percolate;

[0025] S3: Concentrate the percolation liquid with a vacuum film under the conditions of a water bath temperature of 80°C, a vacuum degree of 0.08Mpa, and a feed flow rate of 200-250mL / min, and recover ethanol to obtain a concentrated solution containing 1.5g of raw materials per mL;

[0026] S4: Separating and enriching the obtained concentrated solution through...

Embodiment 1

[0028] Get the following materials in parts by weight: rosin resin 30, polyamide resin 25, ethylene glycol ether acetate 20, zinc borate 10, polybenzimidazole 6, ultraviolet absorber 9, nickel oxide 2, manganese oxide 3, magnesium oxide 1 , organic pigments 9, plant insect repellent and bacteriostatic agent 2. Mix the above substances evenly to obtain the anti-corrosion reflective coating.

[0029] The preparation method of the plant insect-proof and bacteriostatic agent included in the corrosion-resistant reflective paint of the present invention comprises the following steps:

[0030] S1: Beat mint, garlic, ivy and begonia with a weight ratio of 1.5:1.8:1:2.5 into coarse powder, and pass through a 30-mesh sieve;

[0031] S2: Put mint, garlic, ivy and begonia coarse powder into the percolation cylinder, and use 60% hydrous ethanol for percolation extraction. If the weight of raw materials is 1kg, the amount of hydrous ethanol is 10 liters, and the flow rate is 8mL / min. coll...

Embodiment 2

[0035] Get the following materials in parts by weight: rosin resin 33.6, polyamide resin 27.2, ethylene glycol ether acetate 23.4, zinc borate 13.3, polybenzimidazole 7.1, ultraviolet absorber 11, nickel oxide 4, manganese oxide 5.8, magnesium oxide 2.2 , Organic pigment 12, plant pest control and antibacterial agent 3.5. Mix the above substances evenly to obtain the anti-corrosion reflective coating.

[0036] The preparation method of the plant insect-proof and bacteriostatic agent included in the corrosion-resistant reflective paint of the present invention comprises the following steps:

[0037] S1: grind mint, garlic, ivy and begonia with a weight ratio of 1.8:2.1:1:2.7 into coarse powder, and pass through a 30-mesh sieve;

[0038] S2: Put mint, garlic, ivy and begonia coarse powder into the percolation cylinder, and use 60% hydrous ethanol for percolation extraction. If the weight of raw materials is 1kg, the amount of hydrous ethanol is 10 liters, and the flow rate is 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com