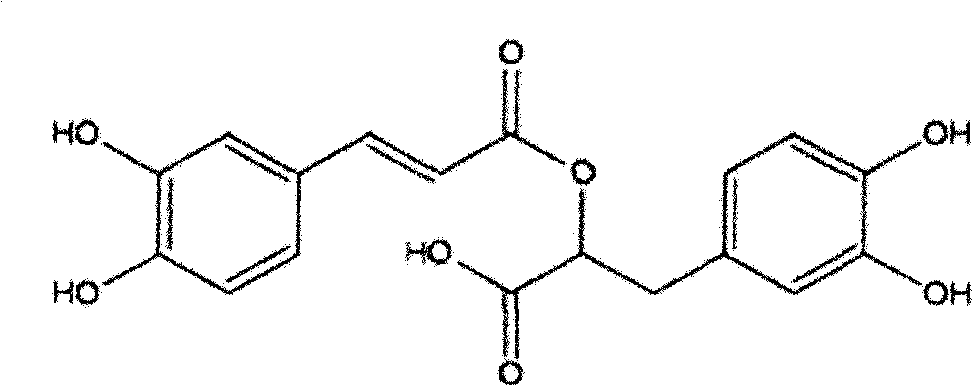

Preparation process of rosmarinic acid

A technology of rosmarinic acid and preparation process, applied in the separation/purification of carboxylate, organic chemistry and other directions, can solve the problems of large amount of ethanol, low product purity, low extraction rate and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] After crushing 20kg of Prunella vulgaris, soak in 240L of water at 60°C for 4 hours, then ultrasonically extract for 30 minutes, filter, add 60L of 15% ethanol to the filter residue for reflux extraction for 1 hour, filter, combine the two filtrates, add 560g of sodium metabisulfite, and then add Equal amount of 004×7 strong acidic cation exchange resin, stir while adding, let stand for 1 hour, filter and concentrate to 1 / 10 of the original volume, take 15 times the amount of 120-200 mesh neutral alumina column, add the concentrated solution to the column Adsorption, sequentially measure 2BV petroleum ether, 7BV ethyl acetate, 3BV30% ethanol, 2BV80% ethanol to elute, collect rosmarinic acid fraction, then add 5% activated carbon and indirectly heat to 60°C, stir for 30 minutes, and pump while hot Filtrate, then add 2% diatomaceous earth, heat to 50°C, stir and absorb for 30 minutes, filter and concentrate through KJ-NSRO-30 (4040) nanofiltration membrane, recover reagent...

Embodiment 2

[0027] After crushing 50kg of Eupatorium, soak in 750L of water at 55°C for 5 hours, then ultrasonically extract for 20 minutes, filter, add 200L of 30% ethanol to the filter residue for reflux extraction for 0.5 hours, filter, combine the two filtrates, add 450g of hydrogen peroxide, and then Add the same amount of D113 macroporous cation exchange resin, stir while adding, let it stand for 4 hours, filter and concentrate to 1 / 15 of the original volume, take 18 times the amount of pretreated XAD-761 macroporous resin to pack, add the concentrated solution Column adsorption, sequentially measure 2BV petroleum ether, 6BV ethyl acetate, 4BV30% ethanol, 2BV80% ethanol to elute, collect rosemarinic acid fraction, then add 2% activated carbon and indirect heat to 60 ° C, stir for 45 minutes, while hot Suction filtration, then add 1% diatomaceous earth, heat to 40°C, stir and absorb for 30 minutes, filter and concentrate through KJ-NSRO-30 (4040) nanofiltration membrane, recover the r...

Embodiment 3

[0029] Crush 50kg of mint and soak in 700L of water at 80°C for 3 hours, then ultrasonically extract for 45 minutes, filter, add 150L of 50% ethanol to the filter residue for reflux extraction for 2 hours, filter, combine the two filtrates, add 800g of sodium metabisulfite, and then add Measure 001×7 strong acidic cation exchange resin, stir while adding, let stand for 3 hours, filter and concentrate to 1 / 12 of the original volume, take 15 times the amount of pretreated HPD400 macroporous resin, and add the concentrated solution to the column for adsorption , sequentially measure 3BV petroleum ether, 5BV ethyl acetate, 5BV30% ethanol, 2BV80% ethanol to elute, collect the rosmarinic acid fraction, then add 5% activated carbon and indirectly heat to 60°C, stir for 60 minutes, and suction filter while hot , then add 1% diatomaceous earth, heat to 50°C, stir and adsorb for 30 minutes, filter and concentrate through KJ-NSRO-30 (4040) nanofiltration membrane, recover the reagent, add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com