CeO2 mesocrystals as well as preparation method and application thereof

A technology of mesoscopic crystals and mixed solutions, applied in chemical instruments and methods, catalyst carriers, chemical/physical processes, etc., can solve problems such as high cost and pollute the environment, and achieve good crystallinity, good monodispersity, and high yield. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Dissolve 7.68 g of ceric ammonium nitrate and 5.97 g of sodium sulfate in 50 mL of deionized water, calibrate the above mixed solution to 70 mL with deionized water, and then transfer it to a high-temperature reactor with a volume of 100 mL (that is, the molar concentration of ceric ammonium nitrate 0.2 mol / L, the molar ratio of ammonium cerium nitrate to sodium sulfate is 1:3). The reaction kettle was put into a blast drying oven, the reaction temperature was controlled at 150 °C, and the reaction time was 5 h. The obtained product was washed by centrifugation to remove impurity ions and then dried at 60 °C for 8 h to obtain CeO 2 mesoscopic crystals.

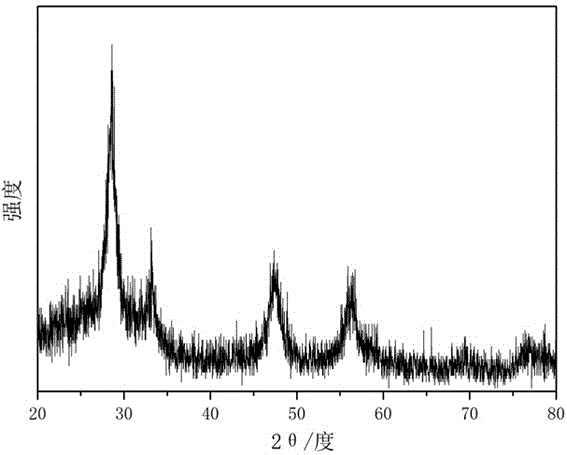

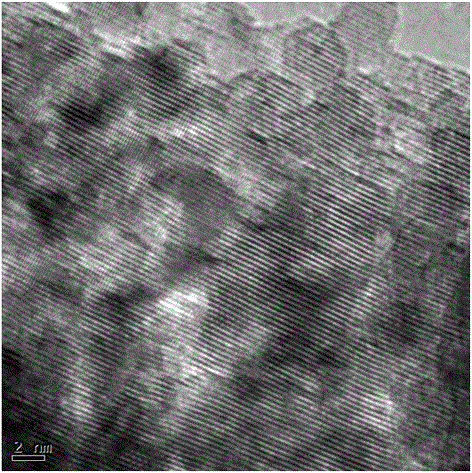

[0024] figure 1 It is the CeO prepared in this example 2 XRD patterns of mesoscopic crystals. Depend on figure 1 It can be seen that the product prepared in this embodiment is pure CeO 2 .

[0025] figure 2 It is the CeO prepared in this example 2 SEM images of mesoscopic crystals. Depend on figure 2 It can...

Embodiment 2

[0029] Dissolve 7.68 g of ceric ammonium nitrate, 0.11 g of ammonium nitrate, and 7.32 g of potassium sulfate in 50 mL of deionized water, calibrate the above mixed solution to 70 mL with deionized water, and transfer it into a high-temperature reaction kettle with a volume of 100 mL (ie The molar concentration of ammonium cerium nitrate is 0.2 mol / L, and the molar ratio of ammonium cerium nitrate, ammonium nitrate and potassium sulfate is 1:0.1:3). The reaction kettle was put into a blast drying oven, the reaction temperature was controlled at 170 °C, and the reaction time was 24 h. The obtained product was washed by centrifugation to remove impurity ions and then dried at 60 °C for 8 h to obtain CeO 2 mesoscopic crystals.

[0030] Figure 5 It is the CeO prepared in this example 2 SEM images of mesoscopic crystals. from Figure 5 It can be seen that the prepared CeO 2 The particles are also nano-spherical mesoscopic crystals, and the diameter of the sphere is about 300...

Embodiment 3

[0032] Dissolve 7.68 g of ceric ammonium nitrate, 0.22 g of ammonium nitrate, and 5.55 g of ammonium sulfate in 50 mL of deionized water, calibrate the above mixed solution to 70 mL with deionized water, and transfer it to a high-temperature reaction kettle with a volume of 100 mL (i.e. The molar concentration of ammonium cerium nitrate is 0.2 mol / L, and the molar ratio of ammonium cerium nitrate, ammonium nitrate and ammonium sulfate is 1:0.2:3). The reaction kettle was put into a blast drying oven, the reaction temperature was controlled at 200 °C, and the reaction time was 72 h. The obtained product was washed by centrifugation to remove impurity ions and then dried at 60 °C for 8 h to obtain CeO 2 mesoscopic crystals.

[0033] Image 6 It is the CeO prepared in this example 2 SEM images of mesoscopic crystals. from Image 6 It can be seen that the prepared CeO 2 The particles are also nano-spherical mesoscopic crystals, and the diameter of the sphere is about 200-600...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com