Preparation method of biomass based activated carbon with high CO2 adsorption efficiency

A technology based on activated carbon and CO2, applied in separation methods, chemical instruments and methods, educts, etc., can solve problems such as complex processes, and achieve the effects of extensive sources, excellent recycling, and low prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

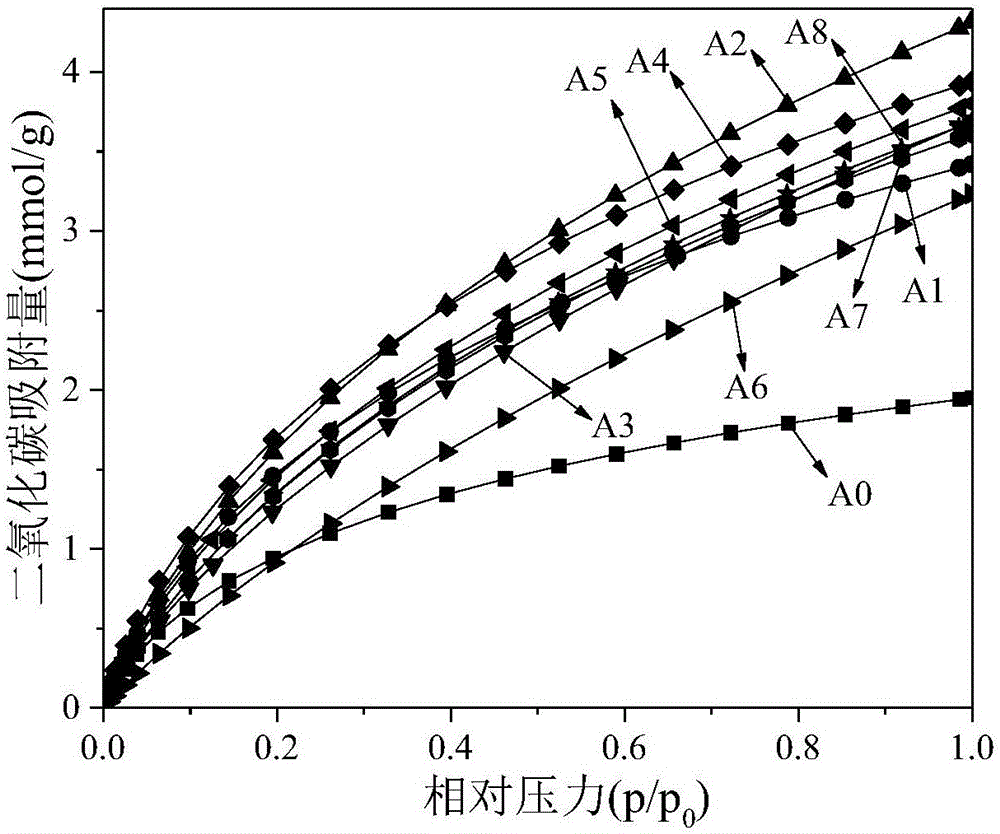

[0032] First, take the pecan husks washed and dried at 110°C for 12h and powder them to 20-40 meshes to obtain pecan husk powder; then, mix 3g of pecan husk powder, 3g of potassium oxalate (pecan husk The mass ratio of powder to potassium oxalate is 1:1) mixed with 30g of distilled water evenly, then transferred to a polytetrafluoroethylene-lined reactor and heated at 240°C for 12 hours to obtain a hydrothermal product; secondly, the hydrothermal product was heated at 110°C After drying for 24 hours, place in N 2 Carbonized material was obtained by carbonizing at 600°C for 2 hours under atmosphere (50ml / min); finally, the carbonized material was repeatedly washed with 0.1mol / L hydrochloric acid and distilled water until neutral, and dried at 110°C for 12 hours to obtain activated carbon. Its specific surface area is 638m 2 / g, its CO 2 The adsorption capacity is 3.42mmol / g (see figure 1 Middle curve A1).

Embodiment 2

[0034] First, take the pecan husk that has been washed and dried at 110°C for 12 hours and powder it to 20-40 meshes to obtain the pecan husk powder; then, mix 3g of pecan husk powder, 9g of potassium oxalate (pecan husk The mass ratio of powder to potassium oxalate is 1:3) mixed with 30g of distilled water evenly, then transferred to a polytetrafluoroethylene-lined reactor and heated at 240°C for 12 hours to obtain a hydrothermal product; secondly, the hydrothermal product was heated at 110°C After drying for 24 hours, place in N 2 Carbonized material was obtained by carbonizing at 700°C for 2 hours under atmosphere (50ml / min); finally, the carbonized material was repeatedly washed with 0.1mol / L hydrochloric acid and distilled water until neutral, and dried at 110°C for 12 hours to obtain activated carbon. Its specific surface area is 999m 2 / g, its CO 2 The adsorption capacity is 4.31mmol / g (see figure 1 Middle curve A2).

Embodiment 3

[0036] First, take the pecan husks that have been washed and dried at 110°C for 12 hours and powdered to 20-40 meshes to obtain pecan husk powder; then, 3g of pecan husk powder, 15g of potassium oxalate (pecan husk The mass ratio of powder to potassium oxalate is 1:5) mixed with 30g of distilled water evenly, and then transferred to a reaction kettle lined with polytetrafluoroethylene and heated at 240°C for 12 hours to obtain a hydrothermal product; secondly, the hydrothermal product was heated at 110°C After drying for 24 hours, place in N 2 Carbonized material was obtained by carbonizing at 800°C for 2 hours under atmosphere (50ml / min); finally, the carbonized material was repeatedly washed with 0.1mol / L hydrochloric acid and distilled water until neutral, and dried at 110°C for 12 hours to obtain activated carbon. Its specific surface area is 1485m 2 / g, its CO 2 The adsorption capacity is 3.69mmol / g (see figure 1 Middle curve A3).

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com