Method for preparing face-centered cubic vanadium nitride nano material and its product

A nanometer vanadium nitride, face-centered cubic technology, applied in chemical instruments and methods, nanotechnology, nitrogen compounds, etc., can solve the problem of high content of impurity elements, limiting the application of nanometer vanadium nitride and the promotion of production technology, and high production costs. problem, to achieve the effect of single composition, easy control of reaction temperature and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

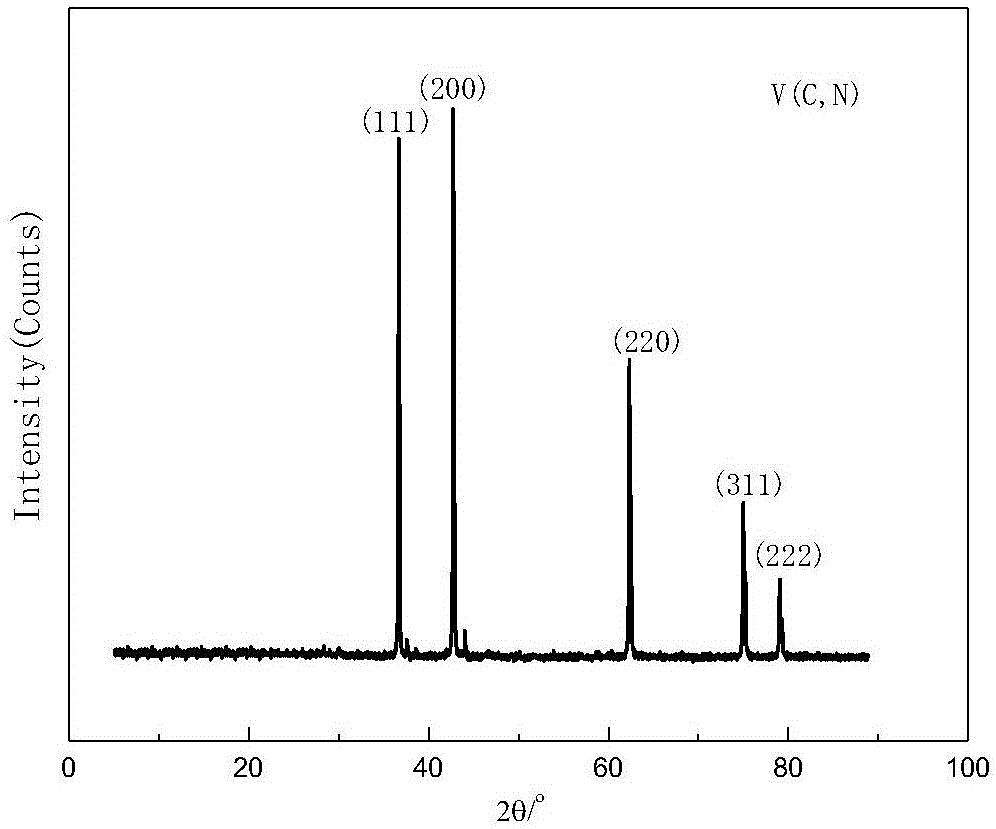

[0029] Get the powdery ammonium vanadate 2g, hydrazine hydrochloride (N 2 h 4 2HCl) 4g and sodium 3g were put into a stainless steel kettle, and the reaction kettle was tightly sealed. Put it into the feed bin of the pusher kiln, increase it from room temperature to 500 °C at a rate of 20 °C / min, and then naturally cool the obtained product to room temperature. Take out the crude product, remove the excess metal sodium with absolute ethanol, then wash with hydrochloric acid, deionized water and absolute ethanol respectively, collect the product, and finally dry it in a vacuum oven at 50°C for 1 hour. The nano-scale vanadium nitride obtained by analyzing the product has a face-centered cubic structure, and the average particle size of the powder is 80-100nm, and the purity reaches 96%.

Embodiment 2

[0031] Get powdered ammonium vanadate 1g, hydrazine hydrochloride (N 2 h 4 Put 2.1 g of 2HCl and 1.6 g of sodium into a stainless steel kettle, and seal the reaction kettle tightly. Put it into the feeding bin of the pusher kiln, increase from room temperature to 450 °C at a rate of 20 °C / min, and then naturally cool the obtained product to room temperature. Take out the crude product, remove the excess metal sodium with absolute ethanol, then wash with hydrochloric acid, deionized water and absolute ethanol respectively, collect the product, and finally dry it in a vacuum oven at 50°C for 1.2 hours. The nano-scale vanadium nitride obtained by analyzing the product has a face-centered cubic structure, and the average particle size of the powder is 100-130nm, and the purity reaches 96%.

Embodiment 3

[0033] Get the powdery ammonium vanadate 3g, hydrazine hydrochloride (N 2 h 42HCl) 6.3g and sodium 4.8g were put into a stainless steel kettle, and the reaction kettle was tightly sealed. Put it into the feeding bin of the pusher kiln, increase from room temperature to 550 °C at a rate of 20 °C / min, and then naturally cool the obtained product to room temperature. Take out the crude product, remove the excess metal sodium with absolute ethanol, then wash with hydrochloric acid, deionized water and absolute ethanol respectively, collect the product, and finally dry it in a vacuum oven at 50°C for 1.5 hours. The nano-scale vanadium nitride obtained by analyzing the product has a face-centered cubic structure, and the average particle size of the powder is 70-90nm, and the purity reaches 97%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com