A leather uncoiling and feeding system

A technology of leather material and material roll, which is applied in the field of uncoiling and feeding mechanism of leather material, which can solve the problems of troublesome loading and unloading, lack of material receiving stations, troublesome connection, etc., and achieve the effects of improving efficiency, reducing complexity, and avoiding slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

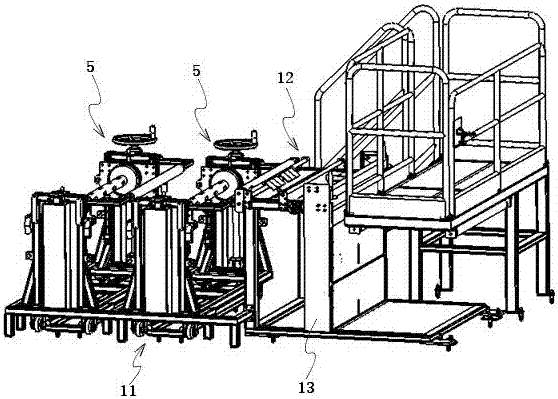

[0036] Such as figure 1 As shown, a leather uncoiling and feeding system includes a berth mechanism 11 , a pretreatment mechanism 12 installed on a frame 13 and an uncoiling trolley 5 .

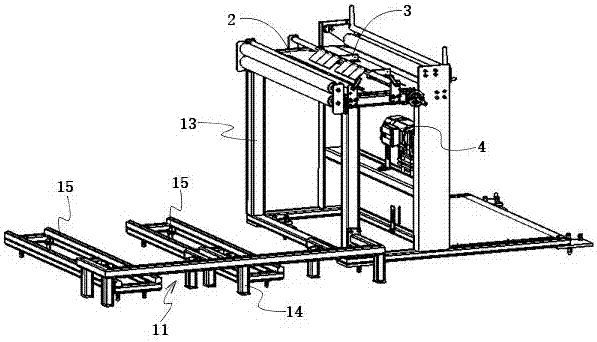

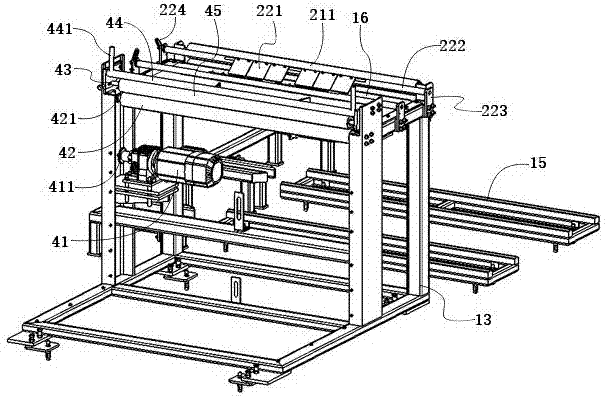

[0037] Berth mechanism 11 is used for unwinding dolly 5 to park, as figure 2 As shown, a parking space frame 14 and a parking track mechanism 15 are included. In this embodiment, there are two berth frames 14 and two berth track mechanisms 15, that is, the berth mechanism 11 can park two uncoiling trolleys 5 at the same time. berth track mechanism 15, such as Figure 4As shown, it consists of a track base 151 and two mutually parallel tracks 152 installed on the track base 151 . Raised ridges 153 are provided on the track 152 . The cross section of the ridge 153 is trapezoidal. On both sides of the ridge 153 are two valleys 154 formed on the top surface of the track 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com