Injection molding machine spray blowing type raw material adding system

A technology of injection and injection molding machines, applied in the field of plastic molding, can solve the problems of inability to meet large-scale production, cluttered pipelines, and many additional equipment, and achieves a compact structure that avoids long-term inefficient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

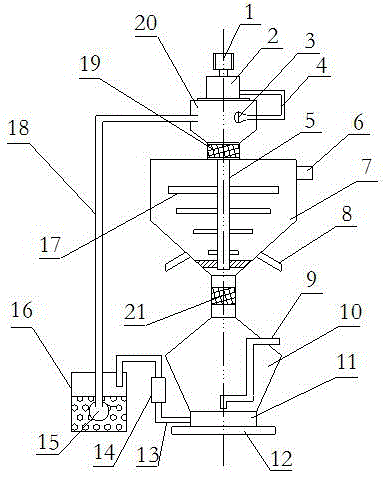

[0015] Such as figure 1 As shown, the injection molding machine injection type raw material addition system of the present embodiment, the injection molding machine injection type raw material addition system includes a raw material tank 6, a collection tank 2, a drying tank 3, a hopper 4 and a blower 5, and the lower part of the hopper 4 is It is fixed on the base 42, and its lower outlet 41 communicates with the screw rod of the injection molding machine. The drying tank 3 is arranged on the upper part of the hopper 4, and its outlet communicates with the raw material inlet of the hopper 4. The collection tank 2 is arranged in the drying tank 4. The upper part of the tank 3, its discharge port communicates with the raw material inlet of the drying tank 3, the blower 5 communicates with the collecting tank 2 through the feed pipe 7, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com