Program control variable-frequency double-shaft compound machine

A compound machine and program-controlled technology, applied in the field of machinery, can solve the problems of increasing production hours and low production efficiency, and achieve the effects of stable precision, strong rigidity and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

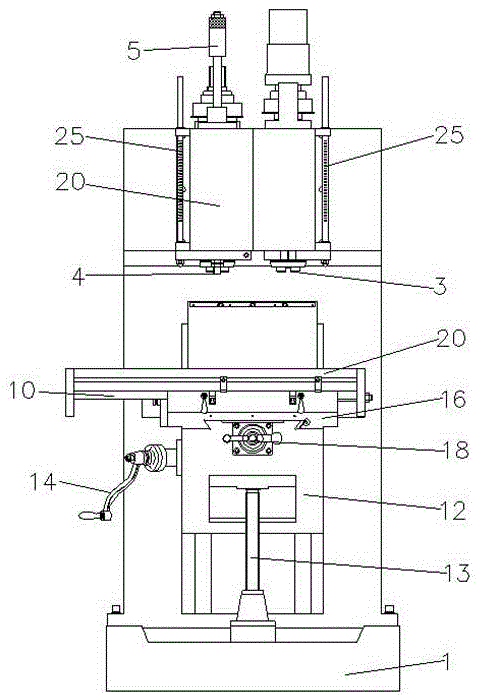

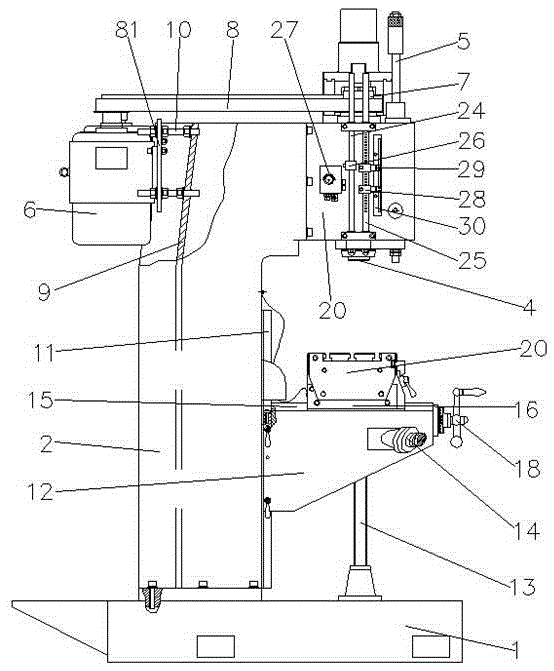

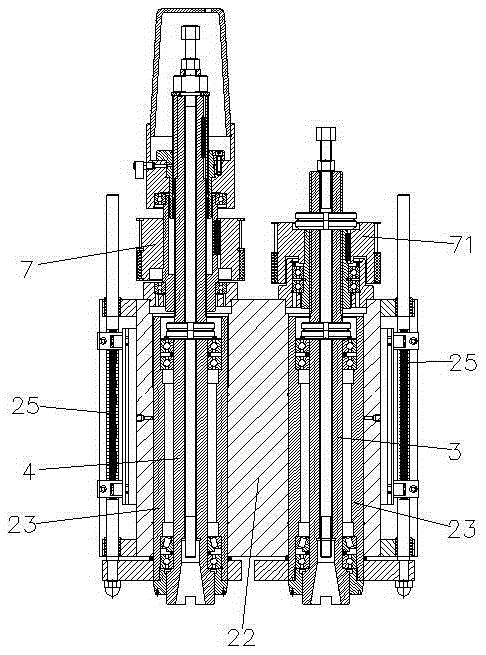

[0023] Please refer to the attached Figure 1 to Figure 4 As shown, the present invention is a program-controlled frequency conversion double-axis composite machine, including a base 1, a column 2 vertically arranged on the base 1, and a workbench transmission device installed on the base 1, installed on the top of the column 2 and located at the working position. The headstock transmission device with drilling shaft 3 and tapping shaft 4 above the table transmission, and two first oil cylinders 5 that respectively drive the drilling shaft 3 and tapping shaft 4 to move up and down, are fixed on the column 2 to drive the drilling shaft 3 and tapping shaft 4 The rotating power transmission device and the main control device connected with the above-mentioned first oil cylinder 5 and the power transmission device;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com