Upright type double-shaft drilling and reaming tapping combined machine tool

A composite machine tool, vertical technology, applied in metal processing mechanical parts, large fixed members, automatic control devices, etc., can solve the problems of increasing production hours and low production efficiency, and achieve strong structural rigidity, stable precision, and high transmission efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below through specific embodiments.

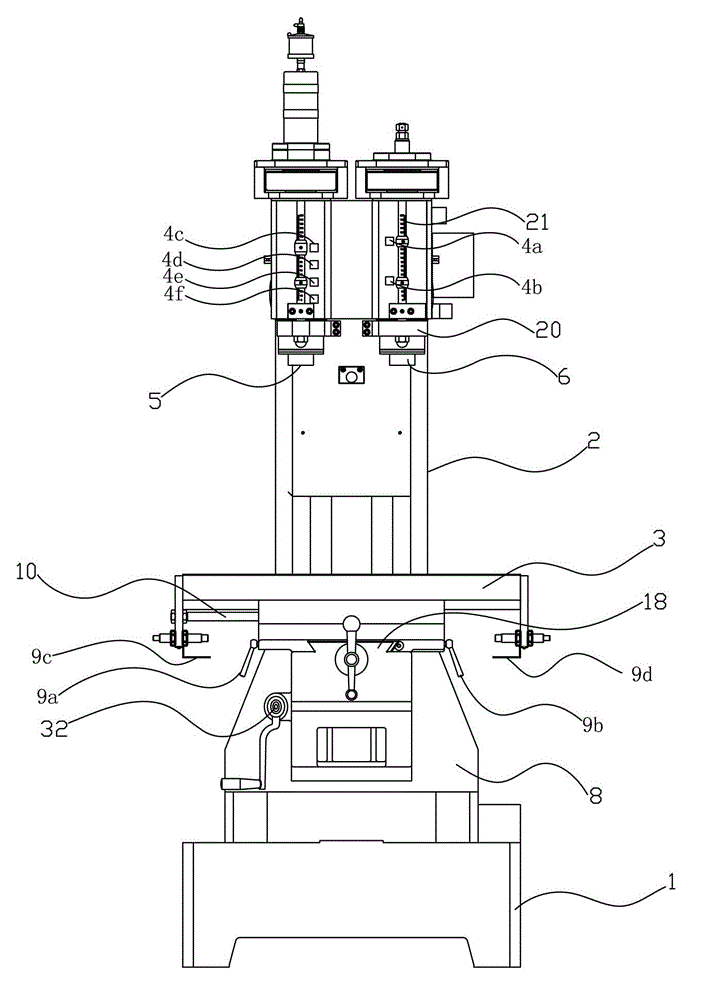

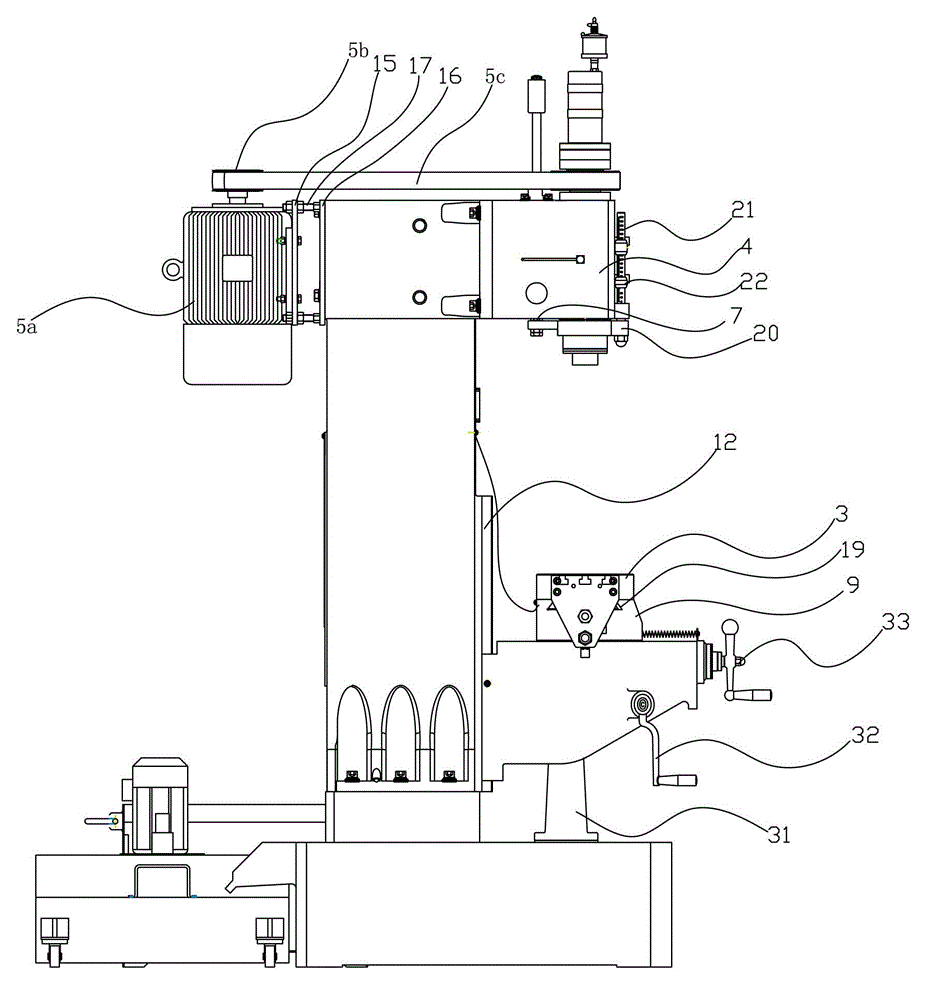

[0020] refer to figure 1 , figure 2 , a vertical double-axis drilling, reaming and tapping machine tool, including a base 1, a column 2 vertically fixed on the base 1, a workbench 3 on the base 1, a drill shaft installed on the top of the column 2 and above the workbench 3 5 and the spindle box 4 of the tapping shaft 6, two first oil cylinders 7 that respectively drive the drilling shaft 5 and the tapping shaft 6 to move up and down, the power unit fixed on the column 2 to drive the spindle box drilling shaft 5 and the tapping shaft 6 to rotate, and the above-mentioned The main control device that the first oil cylinder 7 is connected with the power unit. The power unit includes a first motor, a first synchronous wheel and a first synchronous belt for driving the drill shaft 5 to rotate, a second motor 5a, a second synchronous wheel 5b and a second synchronous belt 5c for driving th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com