A New Type of Process Metal Pipeline Welding Method

A welding method and metal pipe technology, which are applied in metal processing, welding equipment, metal processing equipment, etc., can solve the problems of high cost, difficult to guarantee welding quality, slow welding speed, etc., to reduce construction costs, shorten the welding period, reduce The effect of labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

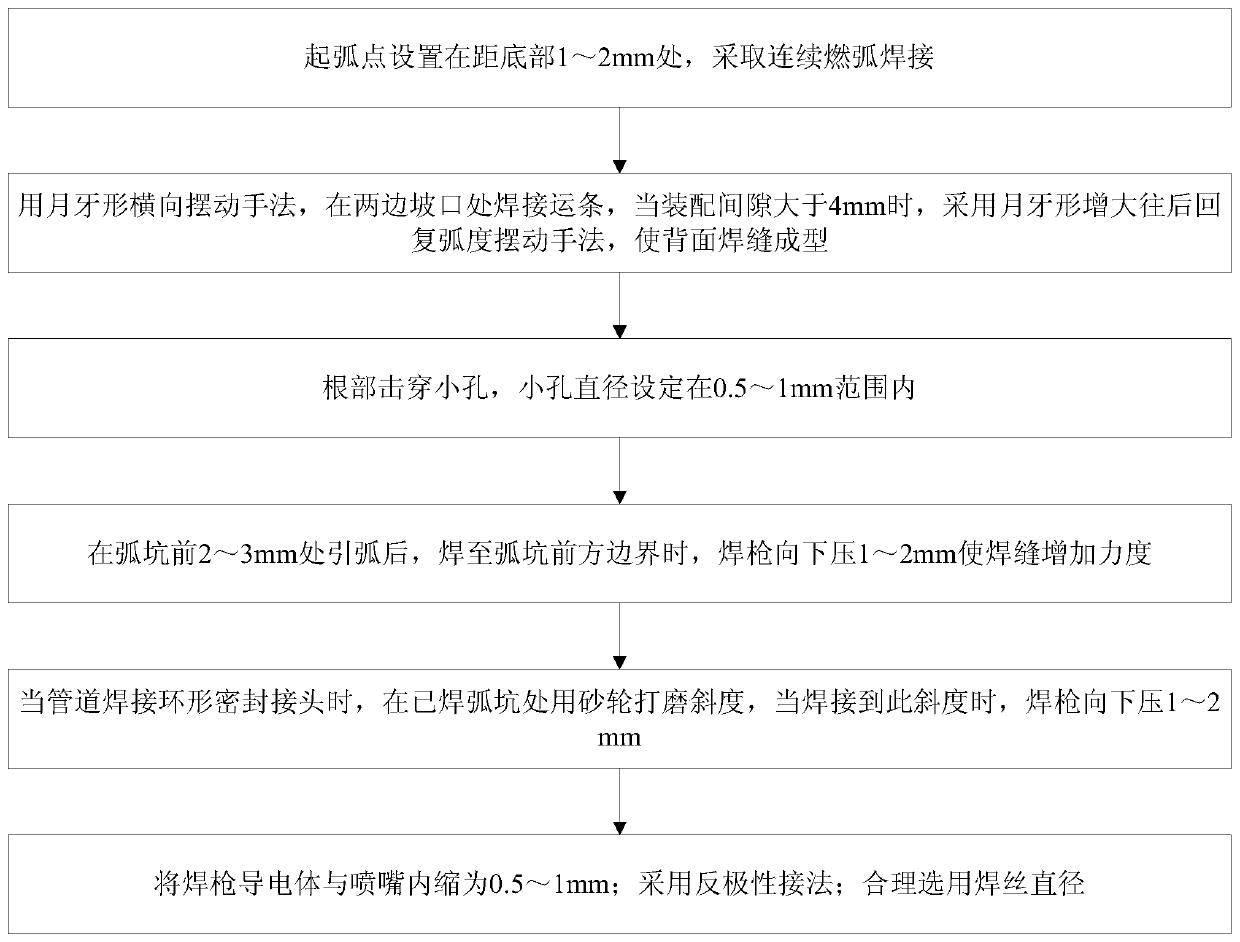

[0026] A new welding method for process metal pipes, see figure 1 , the welding method includes the following steps:

[0027] 101: The arc starting point is set at 1~2mm from the bottom, and continuous arc welding is adopted;

[0028] Among them, if the gap at the arc starting point is too small, the formed weld on the back will leak out, and the fusion weld cannot be formed, and there is an obvious dent boundary at the junction of the two formed welds, and there is no transitional fusion zone. When the gap is too large, it is easy to produce welding bumps, and even the welding penetration cannot be formed normally. Therefore, it is a very critical operation technique to grasp the position of the arc starting point.

[0029] 102: Use the crescent-shaped horizontal swing method to stop for a while at the grooves on both sides to weld the strip. When the assembly gap is greater than 4mm, you can use the crescent-shaped swing method to increase and return the arc, so that the ba...

Embodiment 2

[0045] Below in conjunction with specific construction, the scheme in embodiment 1 is verified for feasibility, see the following description for details:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com