Large-diameter double-nozzle-seat massive forging type main pipeline hot section structure

A technology for taking over the seat and the main pipeline, which can be used in the fields of reactors, greenhouse gas reduction, nuclear engineering, etc., and can solve the problems of high cost and difficult manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

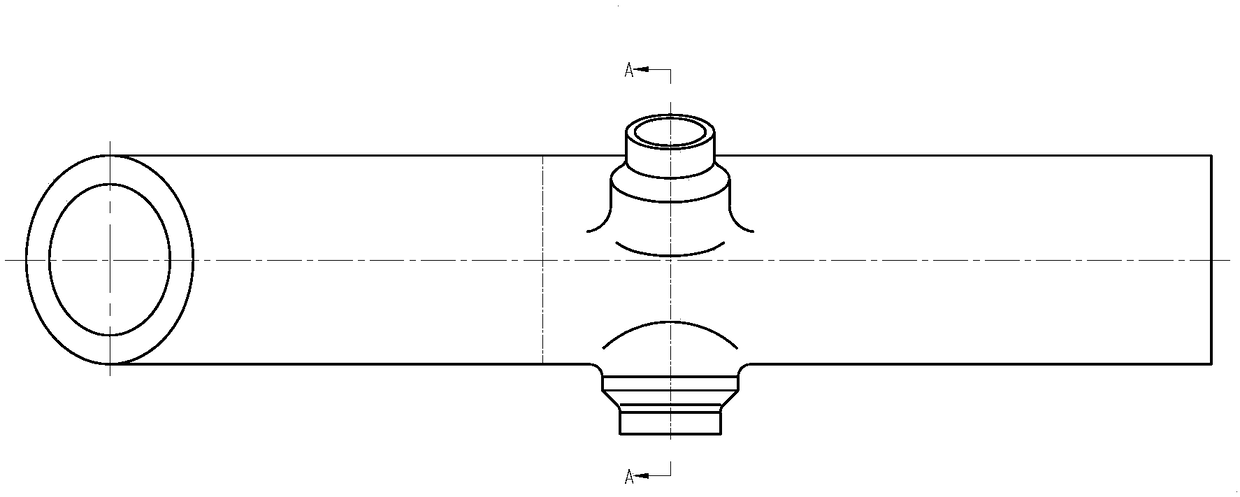

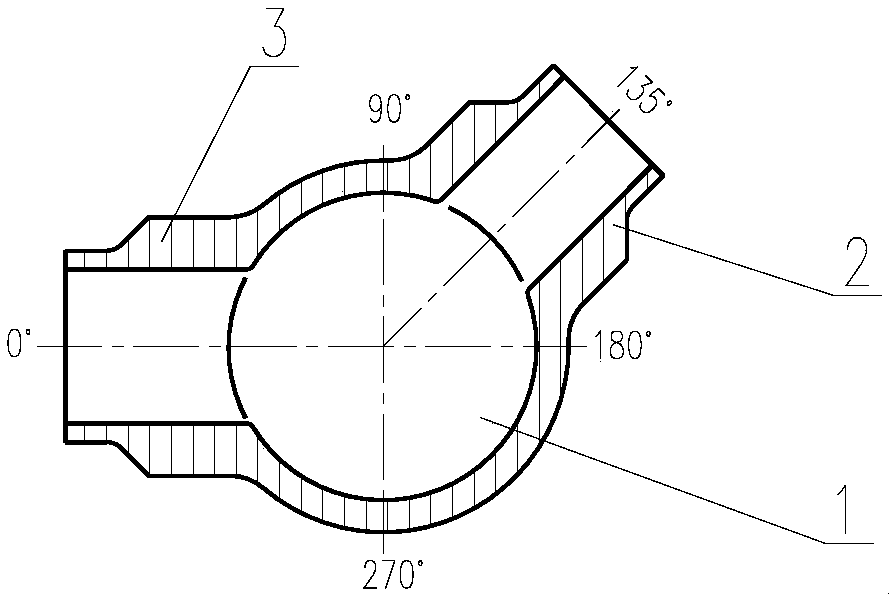

[0037] like figure 1 and figure 2 As shown, the large-diameter double-connection seat integral forged main pipe hot section structure in this embodiment includes the main pipe hot-section body 1, wave pipe connection seat 2 and ADS connection seat 3, and the wave pipe connection seat 2 and ADS The connecting seat 3 is integrally forged and integrally forged with the hot section body 1 of the main pipeline.

[0038] The centerline of the fluctuating pipe connecting seat 2 and the central line of the ADS connecting seat 3 are located on the same vertical plane as the centerline of the hot section body 1 of the main pipe, between the centerline of the wave pipe connecting seat 2 and the centerline of the ADS connecting seat 3 The included angle is 135°.

Embodiment 2

[0040] like image 3 and Figure 4 As shown, the large-diameter double-connection seat integral forged main pipe hot section structure in this embodiment includes the main pipe hot-section body 1, wave pipe connection seat 2 and ADS connection seat 3, and the wave pipe connection seat 2 and ADS The connecting seat 3 is integrally forged and integrally forged with the hot section body 1 of the main pipeline.

[0041] The centerline of the fluctuating pipe connecting seat 2 and the central line of the ADS connecting seat 3 are located on the same vertical plane as the centerline of the hot section body 1 of the main pipe, between the centerline of the wave pipe connecting seat 2 and the centerline of the ADS connecting seat 3 The included angle is 90°.

[0042] In combination with embodiment 1, the included angle between the centerline of the fluctuating pipe socket 2 and the centerline of the ADS socket 3 may be between 45°-135°.

Embodiment 3

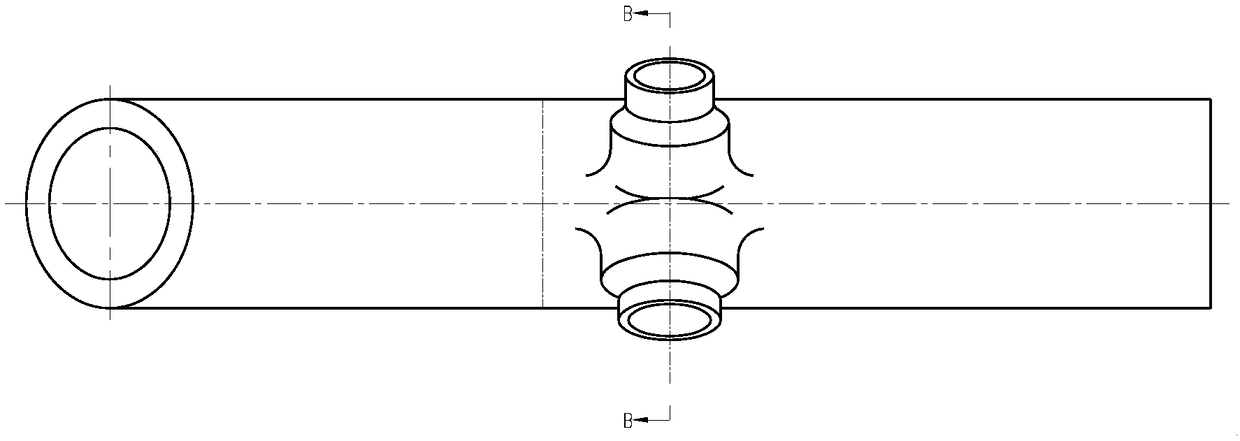

[0044] like Figure 5 and Image 6 As shown, the large-diameter double-connection seat integral forged main pipe hot section structure in this embodiment includes the main pipe hot-section body 1, wave pipe connection seat 2 and ADS connection seat 3, and the wave pipe connection seat 2 and ADS The connecting seat 3 is integrally forged and integrally forged with the hot section body 1 of the main pipeline.

[0045] The center line of the fluctuating pipe connecting seat 2 and the center line of the ADS connecting seat 3 are located on two parallel vertical surfaces of the center line of the hot section body 1 of the main pipeline, and the ADS connecting seat 3 is located behind the wave pipe connecting seat 2 along the incoming flow direction. The included angle between the center line of the fluctuating pipe connection seat 2 and the center line of the ADS connection seat 3 is 135°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com