Turning Tool for Regular Polygon Inner Hole Machining

A regular polygon and inner hole technology, which is applied in the field of turning tooling, can solve the problems that it is difficult to effectively meet the high-precision technical requirements of large-scale mechanical equipment, poor reliability and practicability, and difficult to take out punches, so as to achieve low processing cost and universal Good performance and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

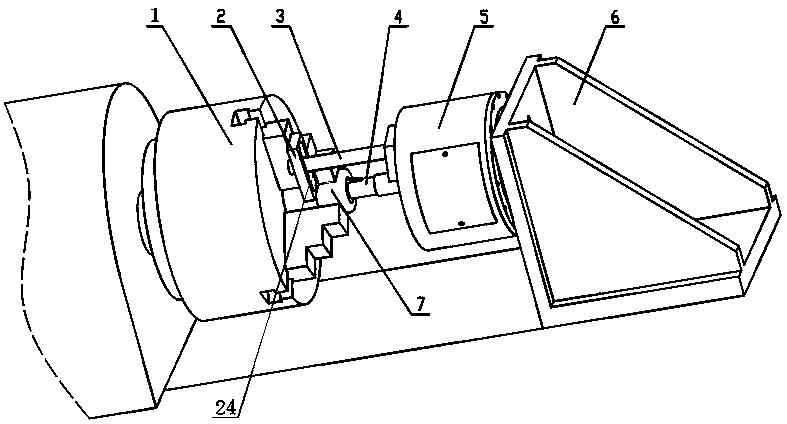

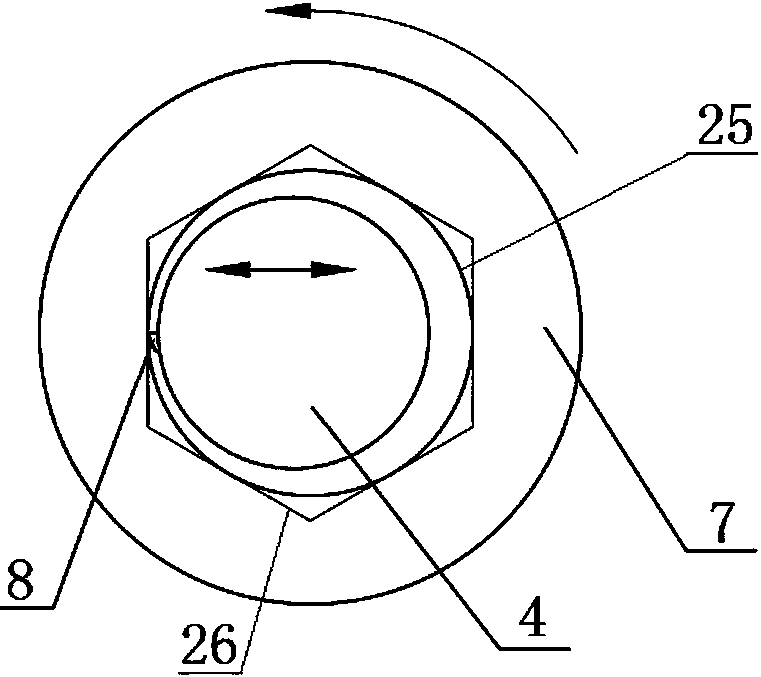

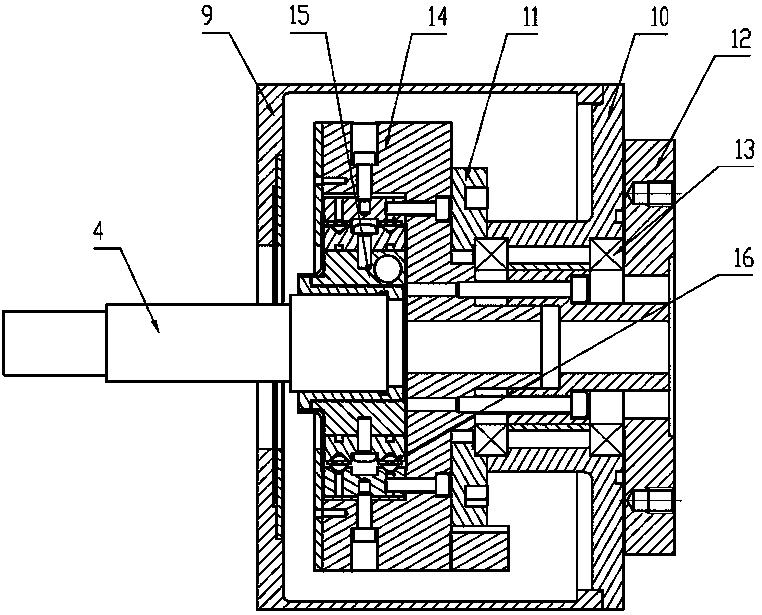

[0030] see figure 1 , figure 2 , image 3 and Figure 4 As shown, the present invention includes a lathe and a tool feed mechanism 5, and the regular polygon inner hole on the workpiece 7 (such as a screw) to be processed is an inner hexagonal hole structure.

[0031] The lathe is a horizontal lathe, and the lathe has a chuck 1 and a tool rest arranged transversely opposite to each other. Chuck 1 is a three-jaw chuck. Chuck 1 is used to clamp the workpiece 7. The processing end surface of the workpiece 7 faces the tool holder. The processing end surface of the workpiece 7 is pre-processed with a circular bottom inscribed in the designed inner hexagonal hole. hole 25; a guide block 2 is fixed on a claw of the chuck 1, and the guide block 2 is arranged along the direction of the claw. The arrangement position of the guide block 2 should avoid the clamping space of the workpiece 7, and the guide block 2 A linear guide hole 24 is provided, and the length of the guide hole 24 ...

Embodiment 2

[0039] The invention includes a lathe and a tool feeding mechanism, and the regular polygonal inner hole on the workpiece (such as a screw) to be processed is an inner hexagonal hole structure.

[0040] The lathe is a horizontal lathe, and the lathe has a chuck and a tool holder arranged transversely opposite to each other. The chuck is a four-jaw chuck. The chuck is used to clamp the workpiece. The processing end of the workpiece is facing the tool holder. On the processing end of the workpiece, a circular bottom hole inscribed in the designed inner hexagonal hole is pre-processed; A guide block is fixed on one of the claws, and the guide block is arranged along the direction of the claw. The arrangement position of the guide block should avoid the clamping space of the workpiece, and a linear guide hole is provided on the guide block. The knife holder is a cross knife holder structure.

[0041] The knife feed mechanism is fixed on the surface of the knife holder facing the ...

Embodiment 3

[0048] The other contents of this embodiment are the same as those in Embodiment 1 or 2, except that the regular polygon inner hole on the processed workpiece is an inner octagonal hole structure; correspondingly, the arc groove on the cam disc is The contour structure of a regular octagon with rounded corners and straight segments with a certain degree of camber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com