Detachable denture and preparation method thereof

A manufacturing method and technology of dentures, applied in the field of dentures, can solve the problems of unsatisfactory requirements of various indicators, weak proficiency and sense of responsibility, and high cost of manual production of dentures, so as to achieve easy control of product composition, convenient cleaning and disinfection, and save Effect of work steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

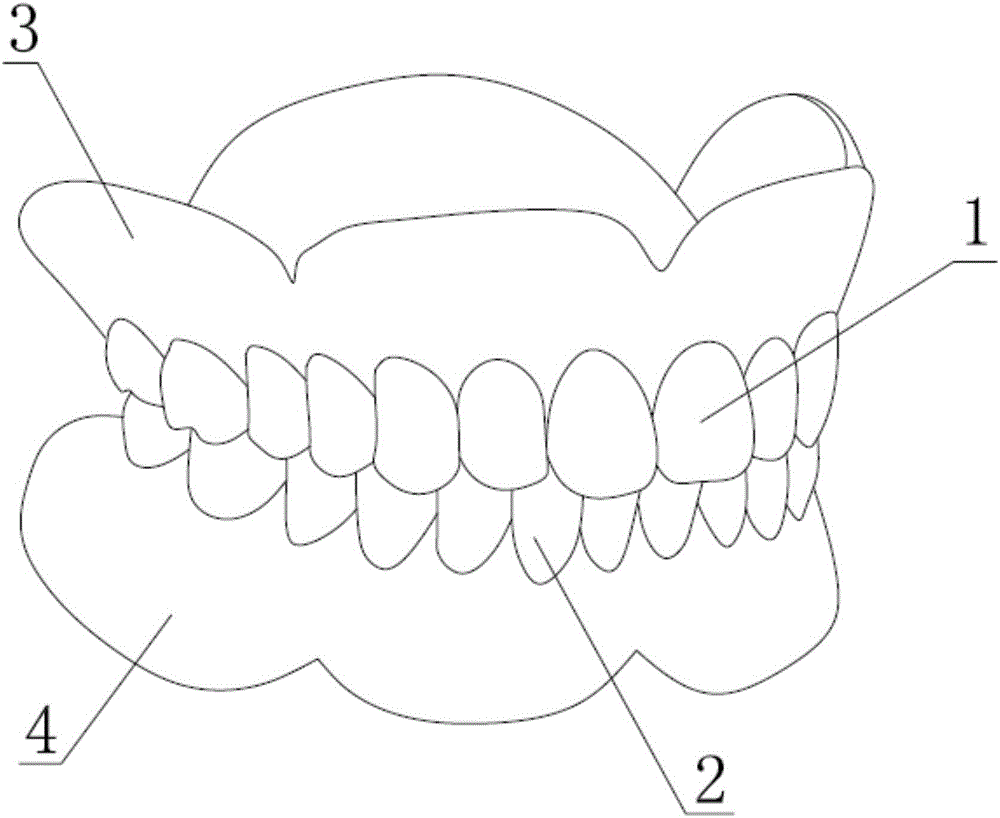

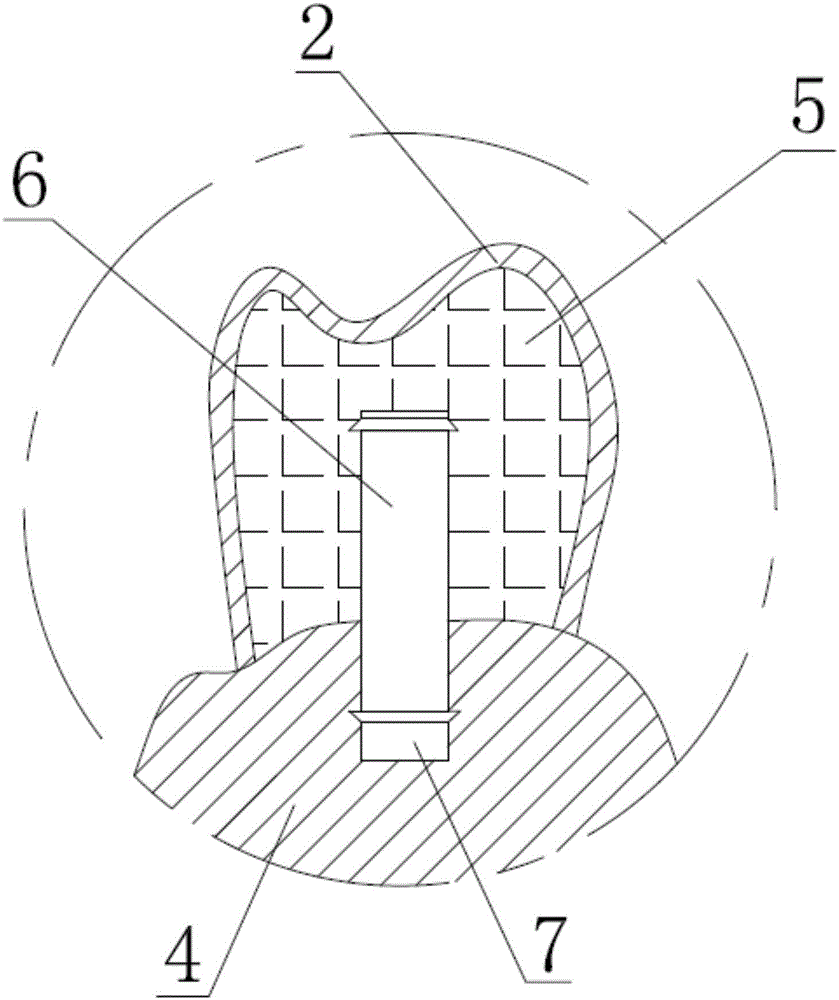

[0035] Such as Figure 1 ~ Figure 2 As shown, a detachable denture, including the installation unit, also includes the upper crown 1, the lower crown 2, the upper tray 3 and the lower tray 4 formed by 3D printing, the upper crown 1 and the lower crown 2 The filling body 5 is filled, and the installation unit includes an implant abutment 6 and an abutment yoke 7, the implant abutment 6 is fixed in the upper crown 1 and the lower crown 2, and the abutment yoke 7 is fixed in the upper tray 3 and the lower In the tray 4, the filling body 5 is filled in the upper crown 1 and the lower crown 2, the abutment yoke 7 is magnetically connected to the implant abutment 6, the upper crown 1 is connected to the upper tray 3, and the lower crown 2 is connected to the lower crown 2. The connection gap between the trays 4 is filled with paste. The present invention has a simple structure, and a single denture forms an integral upper crown 1 and a lower crown 2, and the upper crown 1 and the l...

Embodiment 2

[0059] Step 6, after mixing the photocurable solution and ceramic powder in a volume ratio of 3:1, mix the photocurable solution and ceramic powder in a volume ratio of 3:1, under the premise of ensuring stable photocuring operation , reduce the mixing amount of ceramic powder, reduce the time of the photocuring step, and speed up the photocuring efficiency, and the upper and lower crown prime blanks after photocuring are sintered at a temperature of 800 ° C, and then kept for 3 hours, the shrinkage time Less, large shrinkage, but the strength of the formed porcelain body is higher.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com