Processing method of Zijuan flower tea

A processing method and technology for purple azalea tea, applied in the field of tea processing, can solve the problems of difficult preparation process, inconsistent quality, difficult to ensure stable purple soup color, etc., and achieve simplified processing technology, improved aesthetics, and better shape of tea leaves. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

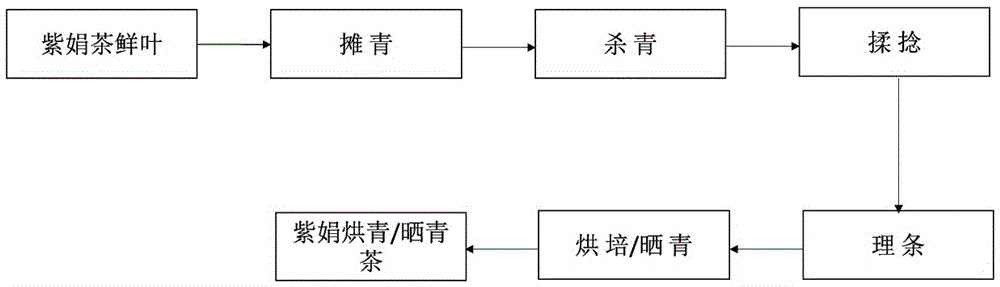

Embodiment 1

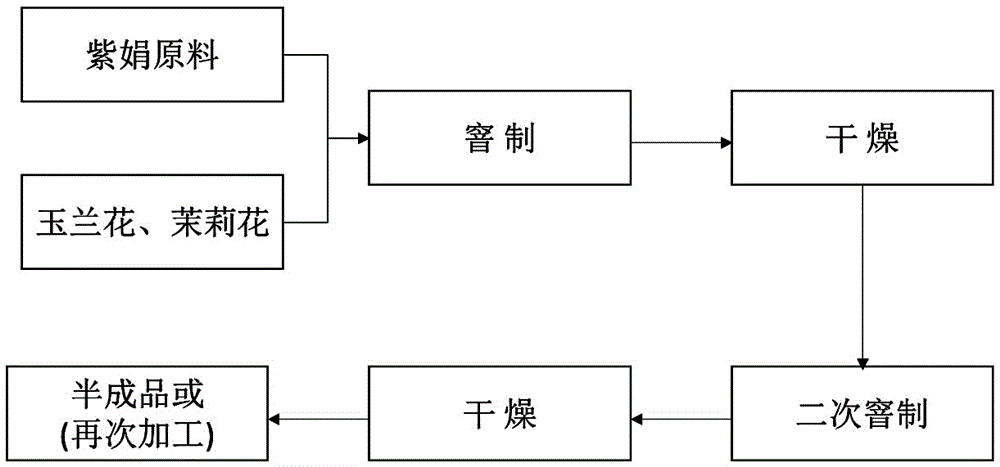

[0014] Example 1: Harvest 100 kg of fresh Zijuan with one bud and two leaves, spread green according to the thickness of 10 cm, let it dry for 8 hours, and then use the green fixer to control the temperature at 280°C to carry out the green treatment, and the degree of green fixation is controlled until the grass gas disappears in the fresh leaves Then use the kneading machine to knead. The degree of kneading is controlled so that the tea juice overflows when the tea is held in the hand. Then, the strip machine is used to organize the strips. The temperature of the strips is controlled at 100±5°C for the strips until the rope is tight and straight. Use a dryer for roasting, the primary fire temperature is controlled at 110±5°C for 30-45 minutes, the full fire is 90±5°C for 30 minutes; dry to a moisture content of 13-15wt% to make green raw materials.

[0015] 20 kg of Zijuan baked green raw materials processed above were selected for use, and high-quality magnolia with a mass fr...

Embodiment 2

[0016] Example 2: Pick 100 kg of fresh Zijuan, one bud and one leaf, spread green according to the thickness of 12 cm, spread it out for 8 hours, and then use the temperature control machine to control the temperature of 290°C to carry out the greening treatment, and the degree of greening is controlled so that the green leaves disappear That’s it, then use the kneading machine to knead, the kneading degree is controlled so that the tea juice overflows when the tea is held in the hand, and then the strip machine is used for stripping, and the strip temperature is controlled at 35±5°C for stripping, until the rope is tight and straight Dried in the sun, the thickness of the spread leaves is 0.6 cm, the drying time is 9 hours, and dried to a moisture content of 13-15wt% to make sun-dried green raw materials.

[0017] 20 kg of Zijuan sun-dried green raw materials processed above were selected for use, and high-quality magnolia with a mass fraction of 1.5% of Zijuan sun-dried green...

Embodiment 3

[0018] Example 3: Harvest 200 kg of fresh Zijuan with one bud and two leaves, spread green according to the thickness of 15 cm, let it dry for 8 hours, and then use the green fixer to control the temperature at 300°C to carry out the green treatment, and the degree of green fixation is controlled until the grass gas disappears in the fresh leaves That’s it, then use the kneading machine to knead, the kneading degree is controlled so that the tea juice overflows when the tea leaves are held in hand, and then the strip machine is used for stripping, and the strip temperature is controlled at 110±5°C for stripping, until the rope is tight and straight It is dried in the sun, the thickness of the leaves is 1.0 cm, the drying time is 12 hours, and the water content is 13~15wt% to make the sun-dried green raw material.

[0019] 50 kg of Zijuan sun-dried green raw materials processed above were selected for use, and high-quality magnolia with a mass fraction of 2.0% of Zijuan sun-drie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com