Self-magnetic field accelerated ultra-high enthalpy arc heater

An arc heater, ultra-high technology, applied in the direction of discharge heating, electric heating devices, electrical components, etc., can solve problems such as failure to provide, and achieve the effect of prolonging the test time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

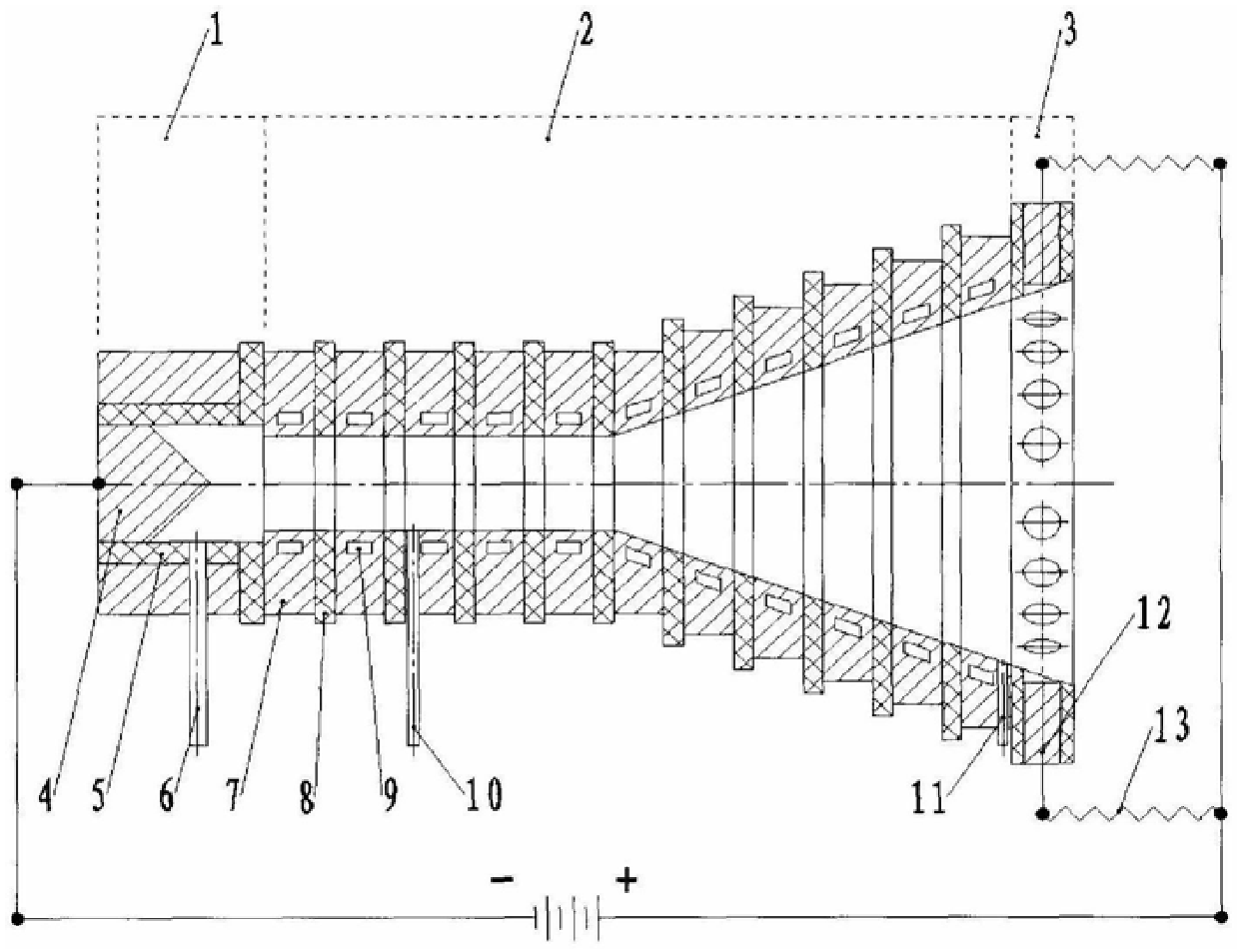

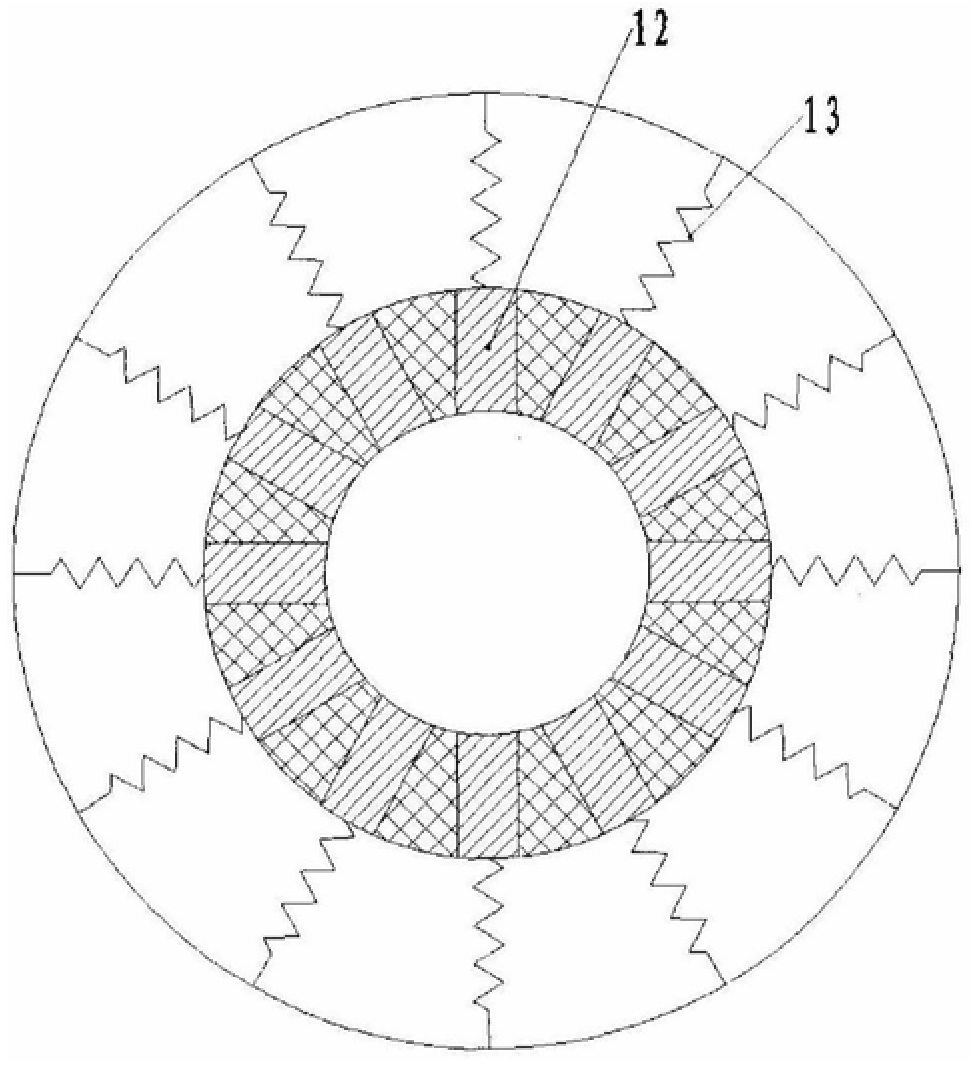

[0012] As shown in Figure 1, the self-accelerated ultra-high enthalpy arc heater is composed of a cathode 1, a nozzle 2, and an anode 3. Each part

Insulate and seal each other.

[0013] The cathode 1 is composed of a cathode rod 4 and a high-temperature-resistant insulating sleeve 5. The working gas passes downstream of the cathode rod 4

The air inlet 6 rotates tangentially to enter. The cathode rod 4 is made of a tungsten alloy with high temperature resistance and low electron overflow work. Cathode 1

It is insulated from nozzle 2 and sealed and fixed.

[0014] The nozzle 2 is composed of a number of water-cooled metal rings 7 and insulating sheets 8 arranged alternately. Water-cooled metal ring 7 and

The number and size of the insulating sheets 8 can be adjusted according to the requirements of the simulation parameters. Each water-cooled metal ring 7 has water-cooled

Road 9. The air inlet 10 downstream of the compression channel can introduce gas of the composition requi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com