Power-driven stripping machine

A peeling machine, electric technology, applied in the installation of circuits, electrical components, cables, etc., can solve the problems of inconvenient artificial intelligence operation, increase the safety of manual operation, etc., and achieve simple structure, precise milling depth, and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

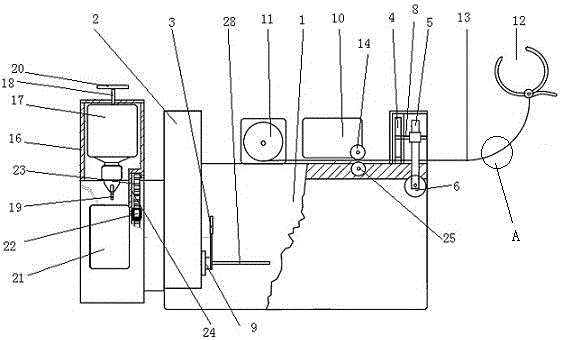

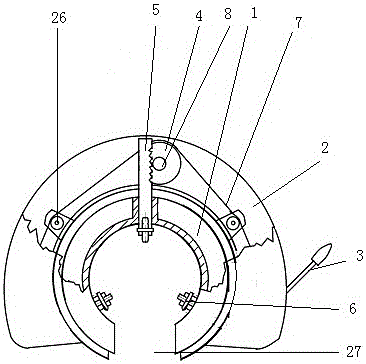

[0019] Below in conjunction with accompanying drawing, the present invention is further described:

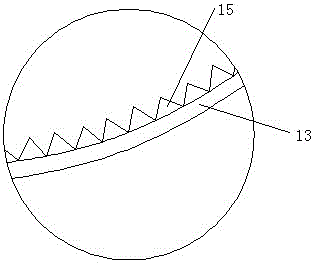

[0020]As shown in the drawings, an electric stripping machine is provided with a cable sleeve 1, which is characterized in that the cable sleeve 1 is provided with a clamping guide mechanism, a traction drive mechanism and a cutting mechanism, and the clamping guide mechanism is located on the cable At both ends of the sleeve 1, the clamping guide mechanism is composed of a clamping housing 2 surrounding the edge of the cable sleeve 1, a positioning clamping assembly and a clamping ratchet handle 3, and the clamping around the edge of the cable sleeve 1 There are at least three sets of positioning and clamping components in the tight housing 2. The positioning and clamping components are composed of a linkage wheel 4, a driving tooth column 5, a guide roller 6 and a connecting drive timing belt 7. The driving tooth column 5 The upper end is connected with the linkage wheel 4 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com