Organic light-emitting device (OLED) display panel, display device and manufacturing method

An electroluminescent display and display panel technology, which is applied in the direction of circuits, electrical components, and electrical solid devices, can solve problems such as low product packaging yield, and achieve the effect of improving yield and high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0046] The present invention provides a solution to the problem that the existing OLED display screen cannot realize in cell touch.

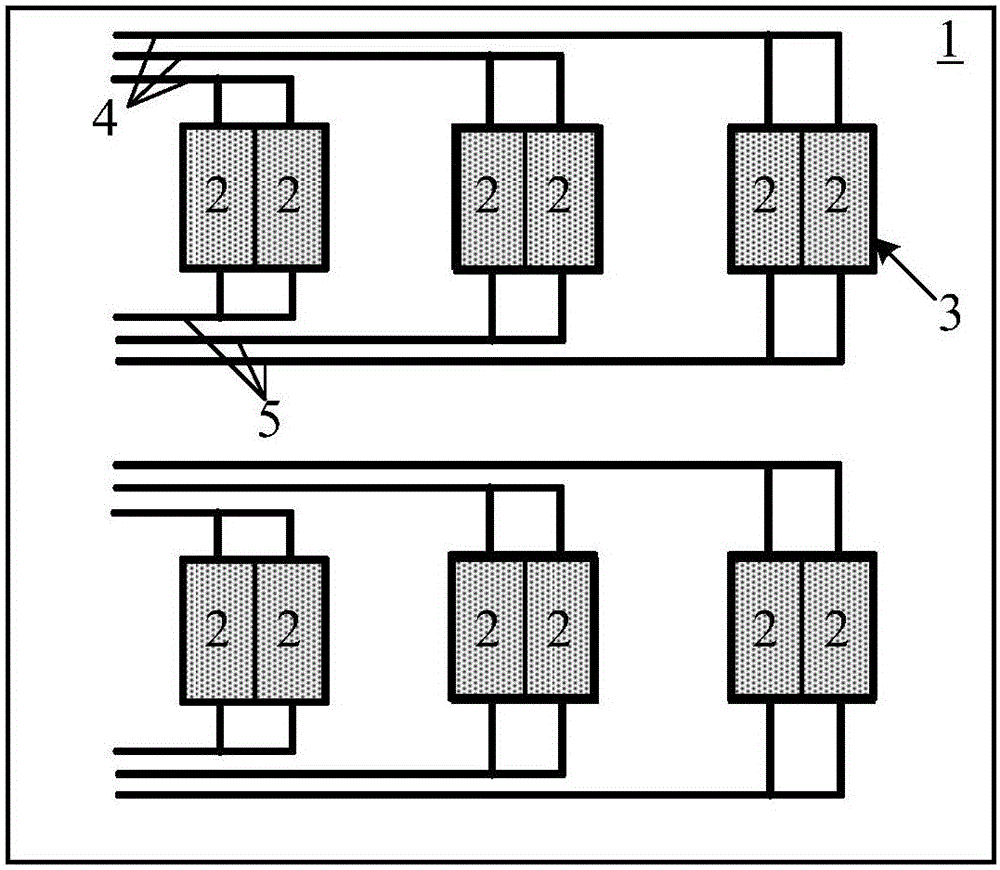

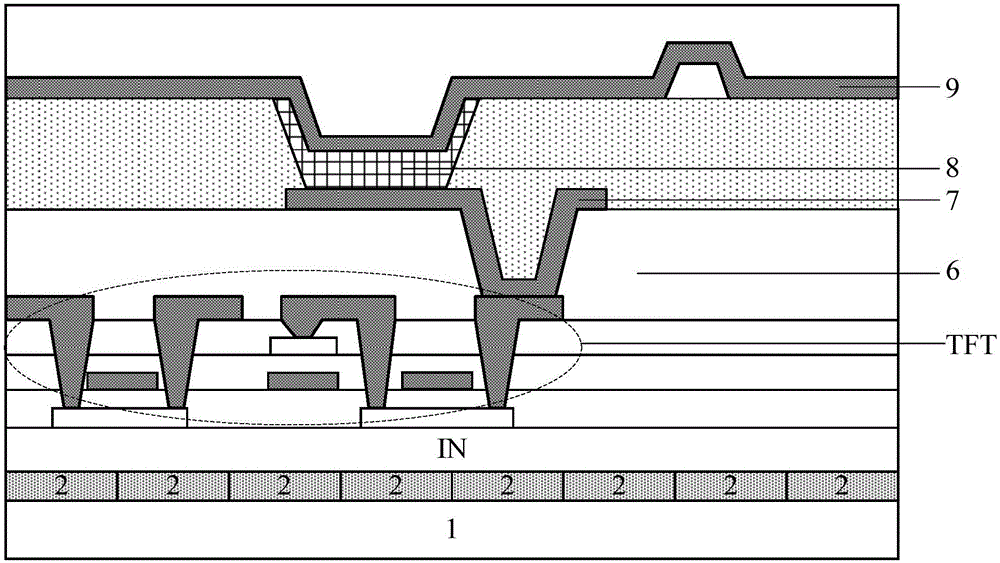

[0047] On the one hand, an organic electroluminescent display panel of the present invention, such as figure 1 shown, including:

[0048] substrate substrate 1;

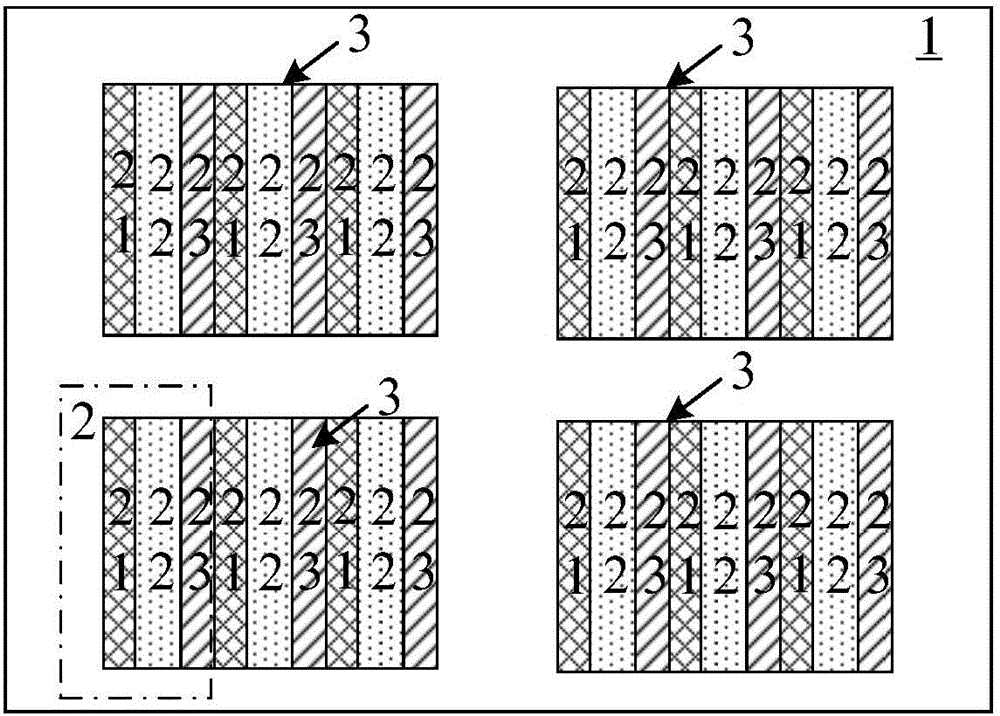

[0049] A plurality of photosensitive elements 2 formed on the base substrate 1;

[0050] A plurality of touch detection units 3, each touch detection unit 3 is composed of at least one photosensitive element 2 ( figure 1 Take two photosensitive elements forming a touch detection unit as an example);

[0051] The signal input line 4 and the signal output line 5 correspond one-to-one to the touch detection unit 3 . The signal input line 4 is connected to the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com