Flexible halogen-free flame-retardant fire-prevention cable and manufacturing method thereof

A fireproof cable, flexible technology, applied in the direction of cable/conductor manufacturing, insulated cable, bendable cable, etc., can solve the problems of difficult to popularize, difficult to promote, expensive equipment, etc., to achieve good market prospects, simple processing technology, Easy to install and install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

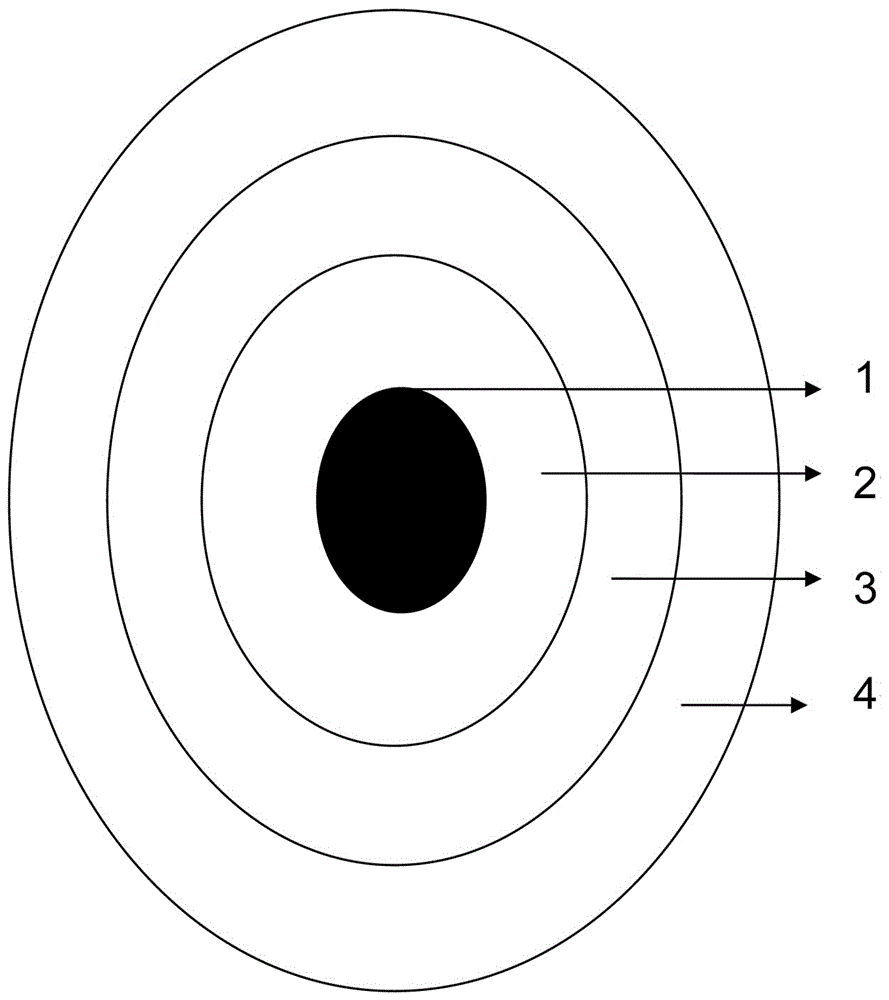

[0017] The copper rod is drawn on a wire drawing machine, then annealed and then coiled for use. 100 parts by mass of dimethyl silicone rubber, 20 parts of silicon dioxide particles with a particle size of 100 nanometers, 2 parts of diphenylsilanediol, 1 part of dicumyl peroxide, 2 parts of other additives, Knead in a vacuum kneader for 5 minutes, then use an internal mixer for 10 minutes to prepare a special rubber / inorganic nanoparticle hybrid composite material, and then pass the special rubber / inorganic nanoparticle hybrid composite material through a rubber cable special extruder , Extruded and coated on the copper core wire at 60°C to form a special rubber / inorganic nanoparticle hybrid composite material insulation fireproof layer. Then the composite mica tape is passed through the wrapping machine, and is overlapped and wrapped on the insulating fireproof layer. The overlapping rate in the wrapping process is 50%, and the wrapping angle is 50°. Mix 100 parts of polyet...

Embodiment 2

[0019] The copper rod is drawn on a wire drawing machine, then annealed and then coiled for use. 100 parts by mass of methyl vinyl silicone rubber, 30 parts of silicon dioxide particles with a particle size of 100 nanometers, 2 parts of diphenylsilanediol, 2 parts of dicumyl peroxide, 5 parts of other additives , kneading in a vacuum kneader for 8 minutes, followed by mixing with an internal mixer for 20 minutes to prepare a special rubber / inorganic nanoparticle hybrid composite material, and then passing the special rubber / inorganic nanoparticle hybrid composite material through a rubber cable special extruder , Extruded and coated on the copper core wire at 80°C to form an insulating fireproof layer. Then the composite mica tape is passed through the wrapping machine, and is overlapped and wrapped on the insulating fireproof layer of the special rubber / inorganic nanoparticle hybrid composite material. The overlap rate in the wrapping process is 30%, and the wrapping angle i...

Embodiment 3

[0021] The copper rod is drawn on a wire drawing machine, then annealed, stranded and coiled for use. 100 parts by mass of ethyl silicone rubber, 25 parts of inorganic silica particles with a particle size of 300 nanometers, 2 parts of diphenyl dihydroxysiloxane, 2 parts of benzoyl peroxide, 2 parts of other auxiliary kneading in a vacuum kneader for 10 minutes, followed by kneading in an internal mixer for 15 minutes to obtain a special rubber / inorganic nanoparticle hybrid composite material, and then the special rubber / inorganic nanoparticle hybrid composite material was extruded for rubber cables Out of the machine, extrude and coat the copper core wire at 70°C to form an insulating fireproof layer. Then the composite mica tape is passed through the wrapping machine, and is overlapped and wrapped on the insulating fireproof layer of the special rubber / inorganic nanoparticle hybrid composite material. The overlapping rate in the wrapping process is 40%, and the wrapping ang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| Overlap degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com